February 15th, 1942. Singapore. When British Lieutenant General Arthur Persal surrendered Singapore to Japanese forces, 85,000 Allied troops became prisoners of war. But the military defeat was only part of the catastrophe. With Singapore’s fall, Japan controlled 60% of the world’s tin production.

Virtually all the tin mining regions of Malaya and the Dutch East Indies. Within weeks, American housewives would discover what military planners already knew. The soup can, as they knew it, was about to disappear. Not because of food shortages, but because of something far more fundamental. America had lost access to the metal that lined every tin can in the country.

Before World War II, the United States imported 97% of its tin, with the majority coming from British Malaya. The country maintained a strategic stockpile of just 75,000 tons, enough for about 1 year of peacetime consumption. When Japan seized Southeast Asia in early 1942, that stockpile became America’s entire tin supply.

This is the documented story of how American engineers facing the complete loss of a critical strategic material reinvented food packaging in 18 months. Replacing traditional tin plate with innovations that would permanently change how food was canned, stored, and distributed. The tin can was a misnomer. A typical food can in 1940 wasn’t made of tin at all.

It was made of steel coated with a microscopically thin layer of tin on both sides. This process called hot dip tin plating had remained essentially unchanged since the early 1800s. Steel sheets were cleaned, dipped in molten tin at approximately 550° F, then cooled. The tin coating, typically just 0.001 to 0.00005 0005 in thick prevented the steel from rusting and protected food from metallic taste.

A standard soup can required approximately 1.5 lb of tin plate containing about 1.5% tin by weight. That meant each can used roughly 0.0225 lb, 10 g of tin. It doesn’t sound like much until you scale up. In 1941, America produced 20 billion cans, consuming approximately 225,000 tons of tin annually just for food packaging.

The tin came overwhelmingly from Southeast Asia. British Malaya alone produced 41% of the world’s tin in 1941 with additional major sources in Dutch East Indies 16% and Thailand 9%. Bolivia was the only significant non-Asian producer at 13% of world supply. American industry depended absolutely on imported tin. Domestic production was negligible.

Small amounts from Alaska and minor recovery from scrap recycling. The United States Geological Survey classified tin as one of the nation’s most critical strategic materials alongside rubber, tungsten, and chromium. When Pearl Harbor was attacked on December 7th, 1941, tin was already in government crosshairs. But planners assumed the Southeast Asian supplies would remain available even during war.

British Malaya was a fortress, Singapore impregnable, the Royal Navy supreme in Asian waters. Those assumptions lasted exactly 10 weeks. Japan’s invasion of Malaya began on December 8th, 1941, the same day as Pearl Harbor across the international dine. The campaign was devastatingly swift. Japanese forces pushed down the Malayan Peninsula, outflanking British defensive positions using bicycles and captured vehicles to maintain rapid advance.

On January 31st, 1942, the last British forces retreated across the Johor causeway to Singapore Island. By midFebruary, Singapore, touted as the Gibralar of the East, was surrounded, its water supply cut, and under constant bombardment. General Persal surrendered on February 15th. Winston Churchill would later call it the worst disaster and largest capitulation in British history.

For American industrial planners, the disaster was also economic. The Kinta Valley tin mines of Malaya, which had supplied America with hundreds of thousands of tons of tin for decades, were now under Japanese occupation. Japan moved quickly to exploit its conquest. By June 1943, despite Allied submarine attacks disrupting shipping, Japan was transporting tin from Malaya.

But the tin was going to Japan, not America. The US strategic stockpile of 75,000 tons looked substantial in January 1942. By March, analysts realized it would last perhaps 16 months at peacetime consumption rates, and wartime would dramatically increase demand. Military equipment required enormous quantities of tin, bronze bearings, 90% copper, 10% tin.

solder for electronics, 60% tin, 40% lead, bronze bushings for vehicles, and of course, food cans for rations. On April 2nd, 1942, the US government imposed the first restrictions. Consumers had to turn in empty tin tubes, toothpaste, shaving cream to purchase new ones. It was a symbolic gesture that signaled the crisis to ordinary Americans.

Your toothpaste tube was now a strategic material. The real blow came in early 1942 when the war production board calculated total tin requirements. Military needs alone would consume the entire stockpile within 2 years. Civilian use, especiallyfood cans, had to be drastically cretailed. On March 1st, 1943, rationing of canned goods began.

Each family received ration points to purchase canned foods from specified categories. Blue stamps in war ration book 2 were designated for canned fruits, vegetables, soups, and juices. But rationing wasn’t a solution. It was triage. America needed to find a way to package food without tin or the military would starve and the home front would face severe shortages.

The most obvious solution was glass jars. Glass required no tin, was domestically produced, and had been used for home canning for decades. The government encouraged this shift aggressively. Posters proclaimed, “Of course I can. I’m patriotic as can be.” And ration points won’t worry me. Companies reformulated products for glass packaging.

Dog food manufacturers prohibited from using tin cans switched to dehydrated products in cardboard boxes or glass jars. By 1943, grocery store shelves showed the transition. Products that had always come in cans now appeared in glass. Some companies adapted successfully. Others found glass prohibitively expensive or impractical for their products.

Glass had serious limitations for military use. It was heavy. A glass jar weighs 3 to five times more than an equivalent tin can. It was fragile. Shipping canned rations to combat zones already involved significant breakage losses. Glass would be catastrophic, and glass production capacity couldn’t be expanded quickly enough to replace billions of tin cans.

In July 1944, recognizing the pressure on home canners, the government released 400,000 pressure cookers for sale, preferably for community use, PTAs and civic organizations purchased them to share within communities. In Antioch, California, the PTA bought a pressure cooker that residents could reserve for home canning sessions.

But community pressure cookers and glass jars couldn’t solve the fundamental problem. America needed industrialcale food packaging that didn’t require tin. Engineers would have to reinvent the can itself. The traditional hot dip tin plating process was wasteful. Dipping steel sheets in molten tin resulted in thick, uneven coatings.

A typical hot dip can used 1.5% tin by weight with coating thickness varying from 0.00001 to 0.00005 in depending on the dipping time. Metallergists had known since the early 1900s that tin could be electroplated onto steel, deposited atom by atom through electrolysis rather than wholesale dipping. Electrolytic tin plating could apply coatings as thin as 0.

00005 in or 50 millionth of an inch uniformly across the entire surface. The math was compelling. Electrolytic tin plate could reduce tin consumption by 80 to 90% compared to hot dip methods while providing equal or better corrosion protection. But electrolytic tin plating required massive capital investment in new equipment.

Pre-war economics made it uncompetitive with established hot dip methods. Steel mills had no incentive to spend millions retooling when hot dip tin plate worked fine and tin was cheap and abundant. The war changed that equation overnight. Tin wasn’t cheap. It was unobtainable. The government was willing to fund capital investment and food manufacturers were desperate for any solution that would keep products on shelves.

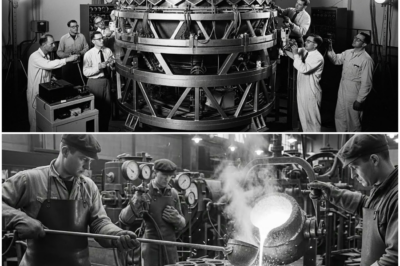

The first modern electrolytic tin plating line in the United States was already under construction when the war began at the US steel plant in Fairless Hills, Pennsylvania. Construction accelerated dramatically in 1942. Other steel mills began planning similar lines. The elegant process clean steel strip passed continuously through electrolytic baths containing dissolved tin salts.

Electric current caused tin ions to migrate from solution and deposit onto the steel surface. By controlling current and line speed, operators could precisely control coating thickness far more accurately than hot dipping ever allowed. After electroplating, the tin coating underwent a refflow process, brief heating above tin’s melting point, 449° F, then rapid quenching.

This fused the tin coating into a smooth bright finish while creating an iron tin alloy layer at the interface that actually improved adhesion and corrosion resistance. The result electrolytic tin plate using only.15 to.25% tin by weight compared to hot dip using 1.5%. A soup can that previously required 10 g of tin could now be made with 1 to 2 g.

By 1943, electrolytic tin plating lines were producing material for food cans. By 1944, significant percentages of American canned goods used the new tin plate. The transition happened faster than anyone thought possible, driven by crisis and government funding. But even 90% reduction in tin use wasn’t enough.

American engineers asked a more radical question. Could steel be coated with something other than tin? The answer came from chromium. Electrochemical research showed that a microscopically thin layer of metallic chromium topped with a film of chromium oxide couldprotect steel from corrosion almost as effectively as tin.

Tin-free steel or TFS, also called electrolytic chromium coated steel or ECCS, was born from wartime necessity. The coating consisted of metallic chromium about 100 to 150 millionth of an inch thick overlaid with chromium oxide a few millionth of an inch thick. TFS had different properties than tin plate.

The chromium coating couldn’t be refflowed into a bright finish. It remained matte. It required lacquer or enamel coating before use with acidic foods. The manufacturing process was more complex than tin electroplating, but it contained zero tin. For certain applications, crown caps, bottle caps, can ends, and containers for non-acidic products.

TFS worked perfectly. It couldn’t fully replace tin plate for all uses, but it eliminated tin consumption for perhaps 20 to 30% of applications. Development accelerated through 1943 to 1944. By war’s end, TFS production lines were operating commercially and food manufacturers were reformulating products to use tinfree containers where possible.

The innovation would have lasting impact. Today, TFS remains a major packaging material worldwide, preferred for its lower cost compared to tin plate and its suitability for certain product types. Aluminum offered another alternative. While aluminum was itself a critical war material, it wasn’t as desperately scarce as tin. Aluminum cans could potentially replace tin cans for some applications.

Pre-war, aluminum cans were rare, used mainly for beer and a few specialty products. Aluminum required different seaming equipment, different processing techniques, and manufacturers were reluctant to invest in retooling. The war changed priorities. Aluminum production was expanding massively for aircraft manufacturing.

Some of that capacity could potentially be diverted to can production, and aluminum required no tin whatsoever. Wartime aluminum can development focused on military rations rather than civilian products. Aluminum’s lightweight, about 1third that of steel, was an advantage for products that had to be carried by soldiers.

Crations and Krations began incorporating aluminum containers were appropriate. But aluminum cans wouldn’t become dominant until the 1960s 1970s when manufacturing processes matured and recycling infrastructure developed. During World War II, they were a niche solution rather than a general replacement for tin plate. While industry retoolled, American households adapted.

Victory Gardens, which produced 40% of American vegetables by 1944, created enormous quantities of produce that needed preservation. Home canning became a patriotic duty. The government published extensive guides. Home canning of fruits, vegetables, and meats from the USDA Bureau of Human Nutrition distributed nationwide.

These guides recommended canning individual vegetables separately rather than mixing to avoid botulism risks. Community caneries, facilities where neighbors gathered to preserve harvests using shared equipment, expanded dramatically. These had existed since the late 1800s, but proliferated during World War I and the depression. By 194344, they were essential infrastructure.

In Jefferson Town, Kentucky, a community canery started by the WPA, Work Projects Administration, was operated by the State Vocational Education Department. Women paid 3 cents per can and 2 cents for pressure cooker use. Similar operations existed nationwide. The advantage, community caneries could obtain tin cans through government allocation that individuals couldn’t.

Processors could also safely handle the high temperature, high pressure sterilization required to prevent botulism, a constant risk in home canning. Glass jar canning at home use different preservation techniques. The classic water bath canning method worked for high acid foods, fruits, pickles, and tomatoes, but was unsafe for low acid vegetables and meats without pressure cooking.

Families learned these distinctions through trial, error, and government education programs. Thousands of pounds of food were successfully preserved by Americans who had never canned before. The learning curve was steep. Improperly sealed jars spoiled. Underprocessed foods harbored bacteria. And mishaps were common. But necessity drove competence.

When you can’t import new tin, you recover old tin. Scrap metal collection became a national mobilization. Children were recruited as junior commandos, digging through attics and basement for old tin items. Families donated pots, pans, metal toys, and broken tools. Storekeepers collected empty tin toothpaste and shaving cream tubes from customers before selling new ones.

The Girl Scouts organized regular can drives across the country. Between November 1942 and March 1943, Americans turned in enough tin containing materials to recover thousands of tons of tin for recycling. Some drives became absurdly ambitious. Actress Rita Hworth removed metal fenders from her car for scrap.

Townsand cities, including Dayton, Ohio, sent historic cannons and monuments to be melted down. Cemeteries salvaged metal fountains and rot iron fences. The recovered material went to dinning plants where tin was chemically stripped from steel. The tin was purified and sent back to tin plate manufacturers. The steel was recycled into new products.

Denning was a mature technology, but capacity had to expand dramatically. By 1943, dinninging plants across America were processing millions of pounds of scrap tin plate monthly. The recovered tin wasn’t enough to meet all needs, but every pound helped stretch the strategic stockpile. Statistics tell the story of transformation.

1941, America consumed approximately 225,000 tons of tin annually with food packaging accounting for the majority. 1943, tin consumption for civilian purposes dropped to approximately 45,000 tons, an 80% reduction. 1945, despite manufacturing more total products, including military rations, total tin consumption remained below pre-war levels.

The reduction came from multiple sources. Electrolytic tin plate reducing tin per can by 80 to 90%. Tin-free steel, eliminating tin entirely for many applications. Glass and cardboard replacing cans for suitable products. Rationing reducing total canned goods consumption. Dinning and recycling stretching available supplies. American industry had accomplished in 3 years what would have seemed impossible in peace time.

Eliminating 4fs of tin consumption while actually increasing food packaging production for military needs. When World War II ended in August 1945, tin supplies gradually normalized as Southeast Asian mines resumed production. Prices dropped. The emergency pressure lifted. But the wartime innovations didn’t disappear. They had proven too valuable.

Electrolytic tin plate became the industry standard. By the 1950s, hot dip tin plating was obsolete in the United States. The superior consistency, reduced cost, and tin savings made electrolytic methods permanently advantageous. Today, virtually all tin plate worldwide is produced electrolytically. Tinfree steel remained in production for applications where its properties were suitable.

Modern TFS production continues, particularly for cann, crown caps, and containers for non acidic products. The technology born from wartime necessity became a permanent member of the packaging material family. Home canning remained popular through the 1950s, though it gradually declined as frozen foods and improved preservation methods made commercial products more convenient.

The pressure cookers released in 1944 stayed in American kitchens for decades. Recycling infrastructure established during the war created pathways for post-war environmental movements. The concept that materials could and should be recovered rather than discarded took root during wartime necessity and grew into modern recycling programs.

The war had fundamentally changed how America thought about resource conservation and material substitution. Industries learned that seemingly indispensable materials could be replaced when necessity demanded it. British forces retook Malaya in 1945, but tin production recovered slowly. Mine equipment had been damaged or destroyed during occupation.

Transportation infrastructure was wrecked. Labor forces were dispersed or dead. By 1950, Malayan tin production had recovered to roughly 60% of pre-war levels. Full recovery took until the mid 1950s. The United States, having learned painful lessons about strategic dependence, began stockpiling refined tin metal from 1946 to 1953 to ensure supply in any future conflict.

The strategic tin stockpile eventually grew to hundreds of thousands of tons, far exceeding the 75,000 tons that proved so inadequate in 1942. But by that time, American industry had learned to use tin efficiently. Consumption per unit of production was a fraction of pre-war levels. In the 1950s to 1960s, aluminium cans began displacing steel cans for beverages.

In the 1970s to 1980s, polymer coatings and laminates created new packaging options. By the 21st century, tin was one option among many rather than an indispensable necessity. The modern food can still exists, though in forms its 1941 ancestor wouldn’t quite recognize. The steel is thinner. The tin coating measured in millionths of an inch.

The interior polymer coated to prevent any metal food interaction. Some tin cans contain no tin at all, aluminium or tinfree steel throughout. The evolution began in 1942 driven by crisis and transformed an entire industry permanently. The tin crisis of World War II demonstrated principles that resonate beyond that particular shortage.

Material substitution is possible when necessary. Technologies considered impossible or uneconomic became viable when circumstances changed. Electrolytic tin plating had been known for decades but wasn’t adopted until crisis made it essential. Government investment can accelerate innovation.

Private industrywouldn’t have spent billions retooling for electrolytic tin plate in peace time. Government funding and guaranteed markets made rapid transformation possible. Constraints drive creativity. Tin-free steel was invented because tin became unavailable. Necessity removed the conservative bias toward existing solutions. Infrastructure changes persist.

Wartime innovations became peacetime standards because they were genuinely better once the engineering challenges were solved. Strategic resource dependence is dangerous. Depending on foreign supplies of critical materials creates vulnerability. Diversification and stockpiling are worth the cost. Modern echoes appear in semiconductor shortages, rare earth element dependencies, and debates about supply chain resilience.

The lessons of 1942 remain relevant. Critical materials require alternatives, stockpiles, and domestic production capacity. In early 1942, the tin can appeared doomed. America had lost access to 60% of world tin production. The strategic stockpile would last barely a year. Food packaging faced collapse, threatening both military rations and civilian nutrition.

18 months later, the crisis had been solved. Not by finding new sources of tin, but by reinventing how tin was used. Electrolytic tin plate reduced consumption by 80 to 90%. Tinfree steel eliminated tin entirely for many applications. Glass, aluminum, and cardboard replaced cans where appropriate.

The soup can survived by transforming itself. The 1945 can looked identical to the 1941 can on the outside, but its metallurgy was fundamentally different, a testament to engineering adaptation under pressure. American households largely didn’t notice the transformation. Soup still came in cans. The cans still opened with can openers. Food tasted the same.

The difference was invisible, measured in millionth of an inch of tin coating that wasn’t there anymore. But in factories, steel mills, and research laboratories, engineers knew that had accomplished something remarkable. They had made a critical strategic material nearly obsolete through innovation, eliminated a vulnerability through technology, and proved that American industry could adapt to any challenge when necessary.

The tin crisis was solved not by conquering Malaysia from Japan, not by discovering new tin mines, but by using almost no tin at all. And that solution, born from desperate wartime necessity, proved so effective that it became the permanent standard. Today, when you open a can of soup, you’re using technology developed in 1942 to 1945 by engineers racing against a ticking clock.

The electrolytic tin plate containing less than 1% of the tin used in pre-war cans. The chromiumcoated steel containing no tin whatsoever. The aluminum can that replaced steel entirely. The soup can was reinvented because America lost Malaysian tin. And the reinvention worked so well that even after tin became available again, nobody went back.

That may be the ultimate measure of innovation when an emergency solution proves superior to the original and necessities inventions become permanent improvements.

News

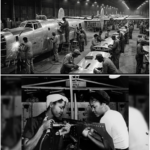

Inside Willow Run Night Shift: How 4,000 Black Workers Built B-24 Sections in Secret Hangar DT

At 11:47 p.m. on February 14th, 1943, the night shift bell rang across Willow Run. The sound cut through frozen…

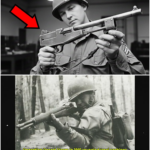

The $16 Gun America Never Took Seriously — Until It Outlived Them All DT

The $16 gun America never took seriously until it outlived them all. December 24th, 1944. Bastonia, Belgium. The frozen forest…

Inside Seneca Shipyards: How 6,700 Farmhands Built 157 LSTs in 18 Months — Carried Patton DT

At 0514 a.m. on April 22nd, 1942, the first shift arrived at a construction site that didn’t exist three months…

German Engineers Opened a Half-Track and Found America’s Secret DT

March 18th, 1944, near the shattered outskirts of Anzio, Italy, a German recovery unit dragged an intact American halftrack into…

They Called the Angle Impossible — Until His Rifle Cleared 34 Italians From the Ridge DT

At 11:47 a.m. on October 23rd, 1942, Corporal Daniel Danny Kak pressed his cheek against the stock of his Springfield…

The Trinity Gadget’s Secret: How 32 Explosive Lenses Changed WWII DT

July 13th, 1945. Late evening, Macdonald Ranchhouse, New Mexico. George Kistakowski kneels on the wooden floor, his hands trembling, not…

End of content

No more pages to load