At 0600 on June 8th, 1944, Technical Sergeant Robert E. Orlowski crouched beneath the left wing of a B17G Flying Fortress at RAF Rattlesden, watching fuel drip from a seal he had just replaced, knowing that in 12 hours, this airplane would carry 10 men into combat over France.

26 years old, three years as an aircraft mechanic, zero missions flown. The 447th Bomb Group had lost 21 B7s in April. Only the Bloody Hundth had lost more bombers in a single month. 11 crew chiefs had watched their fortresses go down. Most never came back. Ori tightened the seal and moved to the number three engine.

The right R1800 Cyclone had logged 42 hours since its last oil change. He pulled the dipstick clean. No metal fragments, but that meant nothing. Engines failed without warning. Hydraulic systems ruptured mid-flight. At any given moment, half the B7s at Rattlesden were grounded with mechanical problems. This particular Fortress had arrived 2 days earlier. Serial number 4337756.

No name yet, no mission marks, just another replacement aircraft in a bomb group burning through fortresses faster than Boeing could build them. Orloski’s job was simple. Keep this airplane flying. Every inspection, every repair, every system check. The crew that flew this fortress would depend on his work to bring them home. 10 men, 10 lives.

His responsibility. He climbed onto the wing and opened the cowling on the number two engine. The ignition harness needed checking. He traced every wire with his fingers, searching for fraying, corrosion, any sign of weakness. One failed wire could cause an engine fire. One engine fire could force an abort.

The 447th had flown its first mission on Christmas Eve 1943. Since then, the group had lost dozens of aircraft. Some to flack, some to fighters, but many simply turned back with mechanical failures, fuel leaks, engine problems, hydraulic failures. A bomber that aborted was a bomber that did not drop its bombs. Ori had learned his trade at technical schools across America.

Engine mechanics, hydraulics, electrical systems, 18 months of training before he ever touched a combat aircraft. Now he was responsible for every system on this fortress. Four engines, fuel system, hydraulics, electrical, oxygen. Every component had to work perfectly every time or men died. The navigator on the first crew assigned to this aircraft was August Altis, a transfer from the 15th Air Force in Italy.

When Altis and his crew returned from their first mission over Berlin on June 21st, someone asked what they thought of flying out of England compared to Italy. Altise said it was a milk run. Easy routine. The crew named their aircraft milk wagon. They painted a cartoon cow on the nose. Between the words milk and wagon.

For every mission the fortress completed, they would paint another milk bottle on the fuselage. White bottles on a black background. Orloski thought it was stupid. A cow. Milk bottles. But the name stuck. And now this silly cartoon was his responsibility, too. He finished the engine inspection and climbed down. The morning briefing would start soon. The ground crews would load bombs and ammunition.

5,000 rounds of 50 caliber ammunition, 2500lb bombs, 2400 g of fuel. Orloski walked around the fortress one more time. He checked the landing gear, the tire pressure, the brake lines. He inspected the control surfaces. Everything moved smoothly, but he knew the statistics. B7s averaged 30 accidents per 100,000 flight hours.

Half of all fortresses in the Eighth Air Force were out of commission at any given time. Some waited for parts. Some waited for repairs. Some would never fly again. If you want to see how Oloski’s obsessive attention to detail kept Milk Wagon flying mission after mission, please hit that like button. It helps us share more forgotten stories like this one. And please subscribe.

Back to Orloski. He stood back and looked at the fortress. The cow looked ridiculous, but this was his airplane now, his responsibility, and he had made a decision that morning that would define the rest of his war. Every other crew chief at Rattlesden maintained their assigned aircraft. They performed the required inspections. They fixed the problems they found. They did their jobs. Ori would do more.

He would inspect every system before every mission. Not just the required checks, everything. He would replace parts before they failed. He would catch problems before they became emergencies. He would turn this cowpainted fortress into the most reliable bomber in the Eighth Air Force. On July 19th, 1944, Milk Wagon was scheduled to fly to a synthetic oil plant in Germany.

That morning, three other B7s at Rattlesden aborted before takeoff with mechanical problems. By noon, two more had turned back over the channel. One with engine trouble, one with hydraulic failure. Orloski watched them return. He knew those crew chiefs, good men, skilled mechanics, but their fortresses had failed. Anyway, Milk Wagon took off at 0730 on July 19th.

Ori watched from the hard stand as the fortress climbed into formation with 35 other B7s from the 447th. The mission lasted 8 hours. The target was hit. The bomber returned without damage, no mechanical problems, no systems failures, no abort. One mission complete, one milk bottle painted on the nose. Ori had the aircraft back in 20 hours.

He performed a complete post-flight inspection. He checked every engine cylinder for cracks. He tested every hydraulic line for leaks. He inspected every electrical connection. He found nothing wrong. The fortress had performed perfectly, but perfect meant nothing if it could not be repeated. Over the next three weeks, Milk Wagon flew seven more missions.

Berlin, Msburg, Munich. Every flight lasted between 6 and 9 hours. Every flight exposed the aircraft to flack, fighters, and the brutal stress of combat formation flying. And every flight, the Fortress returned without mechanical failure. Eight missions, eight milk bottles, zero aborts. Other B7s at Rattlesden were not so fortunate.

On July 24th, three fortresses aborted before reaching the target. Engine failures. On August 1st, two more turned back with hydraulic problems. On August 9th, a B7 suffered electrical failure over Germany and barely made it back on emergency power. Orloski studied every abort. He talked to the other crew chiefs. He learned what had failed and why.

Fuel pumps, oil coolers, supercharger regulators, ignition systems, hydraulic actuators. Every failure taught him something about what could go wrong. And he applied those lessons to Milk Wagon. He began replacing parts before they reached their service limits. Oil filters every 25 hours instead of 50. Spark plugs every 100 hours instead of 200. Hydraulic seals at the first sign of seepage.

He kept detailed maintenance logs. He tracked every component. He knew the history of every part on the aircraft. The other crew chiefs thought he was obsessive. They followed the technical manuals. They performed the required maintenance. They fixed problems when they appeared. Orloski went further. He inspected components that did not require inspection.

He tested systems that were not scheduled for testing. He spent hours tracing wiring, checking connections, hunting for problems that had not yet manifested. By September, Milk Wagon had flown 20 missions, 20 milk bottles on the nose, 20 successful missions without a single mechanical abort, the longest streak in the 708th Bomb Squadron. The pattern continued through autumn.

While other fortresses grounded themselves with mechanical failures, Milk Wagon kept flying, mission after mission. Berlin, Hamburg, Cologne, Keel. The bomber absorbed battle damage, flag holes, shrapnel, damaged control surfaces, but the mechanical systems never failed. Ori and his ground crew repaired the battle damage between missions. They patched holes.

They replaced damaged panels. They straightened bent metal, but the engines, the hydraulics, the electrical systems continued to function without failure. October brought worse weather. Missions through clouds and ice. Temperatures at altitude dropped to 40 degrees below zero. The cold stressed every component. Fuel lines froze. Hydraulic fluid thickened. Electrical systems became brittle.

Other B7s began abboarding with cold weather failures. Milk wagon kept flying. By November, the fortress had completed 50 missions. 50 milk bottles lined the fuselage. The longest uninterrupted mission streak in the 447th bomb group. The longest streak in the Third Air Division. possibly the longest streak in the entire eighth air force. Orloski received orders to report to the group engineering officer.

He walked to headquarters expecting a reprimand. Excessive maintenance, unauthorized part replacements, using resources that could have been spread across multiple aircraft. Instead, the engineering officer asked him how he was doing it. Orloski explained his process.

pre-mission inspections beyond the technical manual requirements, preventive part replacement, detailed maintenance logs, constant monitoring of every system. The engineering officer listened. He did not order to change his methods. He did not criticize the extra maintenance. He simply told Orloki to continue what he was doing.

Milkwagon was now the most reliable bomber at Rattlesden. When other aircraft aborted, Milkwagon completed the mission. When mechanical failures grounded half the bomb group, Milk Wagon was ready to fly. By December 1944, Milkw Wagon had flown 70 missions.

The fortress was approaching the highest mission count of any B7 in the European theater, and the war was far from over. On December 16th, Germany launched a massive counteroffensive through the Arden’s forest. The Battle of the Bulge had begun. The eighth air force would fly maximum effort missions against German supply lines. Every available bomber would be needed, including Milk Wagon. Ori performed his pre-mission inspection on December 24th, Christmas Eve.

The temperature on the flight line was below freezing. Ice covered the wings. He checked the oil one more time. He tested the hydraulics one more time. He inspected the electrical connections one more time. Everything appeared normal, but the mission ahead would be brutal.

The weather forecast predicted heavy clouds over Germany, icing conditions above 15,000 ft, limited visibility. Milkwagon took off at 0800. The mission was a strike against German rail yards near Collins. The Eighth Air Force sent over 700 B7s, the largest Christmas Eve mission of the war. The bombers would attack in waves, formation after formation, hour after hour.

The mission lasted 9 hours. Milk wagon returned at 1700 hours. No mechanical failures. Mission 71 complete. Another milk bottle added to the fuselage. The cowpainted fortress had now flown more consecutive missions without abort than any other B7 in the 447th bomb group. But the battle of the Bulge continued. The weather remained terrible. Snow, ice, fog.

Ground crews worked in conditions that made routine maintenance nearly impossible. Engines refused to start in the cold. Hydraulic fluid turned to sludge. Electrical systems failed from moisture and ice. Orloki adapted. He preheated the engines before every mission. He drained and replaced hydraulic fluid more frequently.

He sealed electrical connections with extra insulation. He worked longer hours. He slept less. He refused to let weather become the reason Milkw Wagon aborted. Between December 24th and January 1st, Milk Wagon flew six missions. Six missions in 8 days. Six successful missions without mechanical failure.

Other B7s aborted regularly, cold weather problems, ice accumulation, frozen control surfaces, but Milk Wagon kept flying. By January 1945, the fortress had completed 80 missions, 80 milk bottles. The other crew chiefs at Rattlesden had stopped questioning Orlok’s methods. They watched him work. They saw the results. Some began adopting his techniques.

Preventive maintenance, more frequent inspections, early part replacement. But none matched his obsession. None spent as many hours on pre-flight checks. None tracked component history with his level of detail. None could replicate what he had achieved with Milk Wagon. The war entered its final phase. Allied armies pushed deeper into Germany.

The Eighth Air Force shifted targets, oil refineries, transportation hubs, marshalling yards. The mission tempo increased. More sorties, shorter turnaround times, less time for maintenance between flights. Orloski maintained his standards. Every inspection remained thorough. Every system check remained complete. Every component received the same attention it had received since June. He would not compromise. He would not cut corners.

Not with 90 missions complete. Not when the record was within reach. By February, Milk Wagon had flown 100 missions. 100 milk bottles covered both sides of the fuselage. The cow looked small now, dwarfed by the mission markers. The fortress was famous across the third air division. The bomber that never turned back, the most reliable B7 in England.

Newspaper correspondents came to Rattlesden to photograph the aircraft. They interviewed the flight crews. They asked about the secret to Milk Wagon’s success. The pilots credited the airplane itself. The navigators praised its reliability. The gunners talked about luck. None mentioned Orloski by name. He preferred it that way.

He was not flying the missions. He was not dropping the bombs. He was not facing the flack and fighters. He was simply maintaining an aircraft, doing his job, keeping the fortress flying. But his superiors noticed. On March 15th, 1945, Orloki received orders to attend an awards ceremony.

He reported in his cleanest uniform, unsure what to expect, the group commander read the citation. Bronze Star Medal for exceptionally meritorious service for maintaining B17G serial number 4337756 through over 100 combat missions without a single mechanical abort. The medal was pinned to his uniform. The ceremony lasted 10 minutes. Photographs were taken. Hands were shaken. Then Orloki returned to the flight line.

Milk Wagon was scheduled to fly the next morning. The engines needed checking. The hydraulics needed testing. The electrical systems required inspection. By April, the fortress had flown 120 missions. The end of the war was approaching. German resistance was crumbling. Allied armies were crossing the Rine. The Eighth Air Force was running out of targets.

On April 19th, 1945, Milk Wagon flew mission 128, a strike against a marshalling yard at Inglestat, Germany. The mission was routine, light opposition, no damage. The bomber returned without incident. 2 days later on April 21st, Milk Wagon was scheduled for mission 129. The target was another marshalling yard, Inglestat.

Again, the same target as 2 days earlier. German rail traffic was still moving through the area. The Eighth Air Force wanted it destroyed completely. Orloski performed his pre-flight inspection at0500 mission 129. He checked the engines, the hydraulics, the electrical systems, the control surfaces. Everything functioned normally. The fortress was ready.

But something felt different that morning. The war was ending. Everyone knew it. German forces were collapsing across the front. Soviet armies were in Berlin. American forces were deep into Bavaria. This might be one of the last combat missions the 447th Bomb Group would ever fly. Milkwagon took off at 0715. The mission proceeded without incident.

Light flack over the target. No fighter opposition. The bombs hit the railard. The formation turned for home. By noon, the fortress was back at Rattlesden. Mission 129 complete. No mechanical failures, no aborts. Not on the first mission. Not on the 129th mission. Never. That afternoon, word came down from 8th Air Force headquarters. All combat operations would continue until Germany surrendered.

But the mission tempo would decrease. Targets were becoming scarce. Resistance was minimal. The bombing campaign that had devastated Germany for 3 years was entering its final days. Milk wagons sat on the hard stand at Rattlesden. 129 milk bottles painted on the fuselage. The cartoon cow barely visible behind the mission markers. The most successful B7 in the Third Air Division.

Possibly the most reliable bomber in the entire war. Orloski continued his maintenance routine. He inspected the engines. He checked the systems. He prepared the aircraft for the next mission, but no new missions came. April 21st, 1945 had been Milk Wagon’s last combat flight. On May 7th, Germany surrendered. The war in Europe was over.

The 447th Bomb Group had flown its last mission. The ground crews began preparing aircraft for the flight back to America. Some fortresses would return to the United States. Others would be scrapped in England. Others would be sold for parts. Milk Wagon would fly home. The 447th Bomb Group began redeploying in June. The Air Echelon would ferry their B7s across the Atlantic. The ground echelon would sail on transport ships.

Orloski was assigned to the ground echelon. He would not fly in Milkwagon on its journey home. His war was over. His work was complete. On July 9th, 1945, Milkwagon took off from Rattlesden for the last time. The destination was Bradleyfield, Connecticut. The ferry flight would take 2 days, refueling stops in Iceland and Newfoundland, then home. Orloski watched the fortress climb into the sky.

He had maintained that aircraft for 13 months. From its arrival in June 1944 to its departure in July 1945, he had inspected every system. He had replaced countless parts. He had spent thousands of hours ensuring the bomber would not fail. And it never had. 129 missions, zero mechanical aborts. A record that would never be broken.

A record that might never even be matched. The cowpainted B7 with the ridiculous name had become the most reliable bomber in the Eighth Air Force. Milk Wagon arrived in the United States on July 9th. The fortress was assigned to the 4168 base unit at South Plains Army Airfield in Texas. The bomber would be processed for disposal.

The war was over. The Army Air Forces no longer needed thousands of B7s. Most would be scrapped. Their aluminum would be recycled. Their engines would be salvaged. Their service would be forgotten. On November 21st, 1945, Milk Wagon was sold to the Reconstruction Finance Corporation.

The bomber was flown to Kingman, Arizona, the desert storage facility where surplus aircraft went to die. Thousands of B7s lined the field at Kingman. Rows upon rows of flying fortresses, all waiting to be scrapped. Milk Wagon was cut apart in December 1945. The engines were removed. The wings were separated from the fuselage. The aluminum was melted down. The most reliable bomber in the Eighth Air Force was reduced to raw materials.

No museum claimed it. No organization preserved it. The fortress simply disappeared. But the record remained. 129 consecutive missions without a single mechanical abort. Achieved by a ground crew led by technical sergeant Robert E. Orloki, a mechanic who refused to accept that aircraft failed. A crew chief who believed that obsessive maintenance could overcome the chaos of war. He was right.

The statistics told the story. Between June 1944 and April 1945, the 447th Bomb Group flew 258 combat missions. Those missions involved over 8,000 individual bomber sorties. Of those 8,000 sorties, approximately 15% failed to reach their targets. Most turned back due to mechanical failures.

Milk Wagon flew 129 missions, zero aborts, zero mechanical failures, zero turnbacks. The probability of achieving that record was astronomical. B7s averaged 30 accidents per 100,000 flight hours. Mechanical failures were routine, expected, inevitable. Every aircraft had systems that would eventually fail. Every engine had components that would eventually break.

Every hydraulic line would eventually leak except on Milk Wagon. Orlosk’s achievement was not simply maintaining an aircraft. Every crew chief maintained aircraft. Every ground crew performed inspections and repairs. What made Orloski different was his refusal to accept failure as inevitable. He did not wait for components to break.

He replaced them before they failed. He did not wait for problems to appear. He found them before they manifested. Other crew chiefs followed the technical manuals. Orloski went beyond them. Other mechanics performed required maintenance. Orloski performed maintenance that was not required but was necessary.

Other ground crews fixed problems. Orloki prevented problems. The result was a bomber that never let its crew down, a fortress that completed every mission it started. An aircraft that became legendary for its reliability in an environment where reliability was rare. But Orlowski was not the only person responsible for Milk Wagon’s success.

His ground crew worked alongside him. Assistant crew chiefs, engine mechanics, hydraulic specialists, electricians, armorers, radio technicians. Each specialist maintained their systems with the same obsessive attention to detail that Olski demanded. They worked in terrible conditions. Winter cold that made metal brittle and fingers numb. Summer heat that made the flight line unbearable. Rain, mud, wind.

They worked at night after missions returned. They worked before dawn to prepare aircraft for morning launches. They worked through air raid warnings when German bombers attacked English bases. And they never let Milk Wagon fail. The flight crews also contributed to the record. The pilots who flew the fortress treated it with respect. They followed procedures. They monitored systems carefully.

They reported problems immediately. They did not abuse the aircraft. They understood that their survival depended on the reliability of their machine. The navigators plotted courses that avoided the worst weather when possible. The bombarders operated their equipment carefully. The engineers monitored the engines constantly.

The gunners maintained their weapons properly. Every crew member understood that Milk Wagon’s reputation for reliability was something worth preserving. But ultimately, the record belonged to Orloski. He set the standard. He established the maintenance procedures. He made the decisions about when to replace parts.

He spent the extra hours performing additional inspections. He accepted responsibility for keeping the fortress flying. And he succeeded for 129 consecutive missions. No other B7 in the European theater matched that achievement. Some bombers flew more total missions. Memphis Bell completed 25 and became famous. Hell’s Angels completed 48 in the Pacific.

Other fortresses exceeded 100 missions, but none completed 129 consecutive missions without a single mechanical abort. The difference was abort rate. Most B7s aborted regularly. Mechanical problems forced them to turn back before reaching targets. Engine failures, hydraulic leaks, electrical malfunctions. These were normal occurrences, expected events, part of bomber operations.

Milk wagon never aborted. Every mission started was a mission completed. Every takeoff ended with a landing back at Rattlesden. Every bomb load was dropped on target. The bomber that never turned back. After the war, Orloki returned to civilian life. He settled in Pennsylvania. He worked as a mechanic. He raised a family. He rarely spoke about his wartime service.

The Bronze Star was stored in a drawer. The memories of Rattlesden remained private. He did not consider himself a hero. He had not flown combat missions. He had not faced enemy fighters. He had not dropped bombs on Germany. He had simply maintained an aircraft, done his job, kept a bomber flying.

But his contribution to the war effort was significant. Every mission Milk Wagon completed was a mission that struck at Germany’s ability to wage war. Every bomb load delivered helped shorten the conflict. Every successful sorty brought victory closer, and none of those missions would have happened if the fortress had aborted due to mechanical failure.

The technical challenge of maintaining a B7 flying fortress was immense. The aircraft contained over 400,000 individual parts. Four right R1820 Cyclone engines. Each engine had 18 cylinders. 72 cylinders total across four engines. Each cylinder required inspection. Each spark plug required checking. Each valve required adjustment.

The fuel system included 24 fuel tanks distributed across the wings and fuselage. Miles of fuel lines connected the tanks to the engines. hundreds of connections. Any connection could leak. Any line could rupture. Any valve could fail. A single fuel system failure could force an abort. The hydraulic system powered the landing gear, brakes, bomb bay doors, and turret systems. High-pressure hydraulic fluid flowed through dozens of actuators, valves, and cylinders.

The system operated at over 1,500 lb per square in. A ruptured line could drain the system in minutes. A failed seal could cause gradual pressure loss. Either problem could prevent landing gear extension or bomb bay door operation. The electrical system was equally complex. Generators on each engine produced electrical power.

Distribution panels routed electricity to hundreds of components. Navigation lights, radio equipment, oxygen system heaters, gun turret motors, instrument panel displays. A failed generator meant operating on reduced power. A short circuit could disable critical systems. Orloski mastered every system. He understood how each component functioned. He knew the failure modes.

He recognized the warning signs that preceded breakdowns. He could diagnose problems by sound, by smell, by touch. He could feel a bearing beginning to fail. He could hear an engine running rough before instruments showed problems. His maintenance philosophy was simple. Replace components before they failed, not at their rated service life, before their rated service life.

If a spark plug was rated for 200 hours, replace it at 150 hours. If a hydraulic seal was rated for 500 hours, replace it at 400 hours. If an oil filter was rated for 50 hours, replace it at 30 hours. This approach required more parts, more labor, more maintenance time, but it prevented failures.

A component replaced early would never fail in flight. A seal changed before it leaked would never cause a hydraulic system failure. An oil filter replaced frequently would catch contamination before it damaged an engine. Other crew chiefs considered this wasteful. Parts were expensive. Labor was limited.

Time between missions was short. They replace components when they failed, not before. They followed the technical manuals. They performed scheduled maintenance at prescribed intervals. Orloski proved his method worked. While other B7s aborted with mechanical failures, Milk Wagon completed every mission. While other crew chiefs scrambled to repair broken systems, Orloski prevented systems from breaking.

While other fortresses sat grounded waiting for parts, Milk Wagon was ready to fly. His maintenance logs documented everything. Engine oil analysis results, hydraulic pressure readings, electrical system voltages, component replacement dates, service hours on every part.

When he replaced a fuel pump, he recorded the date, the engine, the total hours on the old pump, and the serial number of the new pump. When he changed spark plugs, he noted which cylinders received new plugs and why. These logs allowed him to identify patterns. He noticed that fuel pumps on the number three engine failed more frequently than pumps on other engines. He began replacing the number three fuel pump more often.

He noticed that hydraulic seals in the landing gear system degraded faster in cold weather. He began replacing those seals before winter missions. He noticed that electrical connections near the bomb bay corroded from exposure to moisture. He sealed those connections with protective coating. Every pattern he identified led to a preventative measure.

Every preventative measure reduced the chance of failure. Every failure prevented meant another successful mission. Over 13 months and 129 missions, those preventative measures accumulated into an unbreakable record. The other ground crew members at Rattlesden respected his methods even if they could not replicate them. They saw the results.

They understood the achievement. They knew that what Orloki had accomplished with Milk Wagon was extraordinary. But they also knew that his success required a level of commitment that few could sustain. The long hours, the obsessive attention to detail, the refusal to accept good enough. Orloski maintained one aircraft.

Most crew chiefs maintained multiple aircraft. They could not spend as many hours on each bomber. They could not track every component with his level of detail. Ori had made Milk Wagon his sole focus. His entire war effort concentrated on keeping one B7 flying. And it worked perfectly. The flight crews who flew Milk Wagon understood what they had. A bomber they could trust.

An aircraft that would not fail them over Germany. A fortress that would bring them home. That confidence affected their performance. They flew more aggressively. They held formation longer. They pressed attacks harder. They knew their aircraft would not let them down. Other crews were not so fortunate.

A pilot whose bomber aborted frequently learned to expect mechanical failures. A navigator whose aircraft turned back regularly planned for abort possibilities. A crew that could not trust their fortress flew more cautiously. They worried about systems failing. They monitored instruments constantly. They prepared for emergencies that might force them to leave formation.

Milk Wagon’s crews flew without that burden. They focused on the mission, on navigation, on bombing accuracy, on formation flying, on defensive gunnery. They trusted Orloki and his ground crew to handle the mechanical reliability. That trust translated into better mission performance. The Eighth Air Force noticed.

By early 1945, Milk Wagon was frequently assigned to lead positions in bomber formations. Lead aircraft required the most reliable bombers. They carried the best navigators and bombaders. They set the course for entire formations. They determined when bomb bay doors opened. They controlled when bombs released.

A lead aircraft that aborted forced the entire formation to reorganize. A lead aircraft that failed could compromise the entire mission. Milk Wagon never failed in a lead position, never aborted, never forced a formation to reorganize. The reliability that ori built into the fortress made it the most trusted bomber in the 447th bomb group. That reliability also meant the aircraft flew more often.

When other B7 sat grounded with mechanical problems, Milk Wagon was available. When missions required maximum bomber strength, Milk Wagon was ready. The Fortress flew more missions because it could fly more missions. The aircraft that never broke down was the aircraft that flew the most. This created a paradox.

Increased flying meant increased wear on components, more engine hours, more hydraulic system cycles, more electrical system usage, more stress on every part. Under normal circumstances, higher utilization led to more failures, more maintenance, more downtime. But Orlok’s preventative maintenance strategy counteracted the increased wear.

By replacing components before they failed, he prevented the accumulation of small problems that led to major failures. By tracking every system closely, he identified wear patterns before they became critical. By maintaining detailed logs, he knew when components approached their limits. The result was an aircraft that flew more missions while maintaining higher reliability than bombers that flew fewer missions. Milk Wagon’s operational availability exceeded 90%.

Most B7s achieved availability rates between 50 and 60%. The difference was Orloski’s maintenance program. The 447th Bomb Group’s engineering staff studied Milk Wagon’s maintenance records. They examined Orlok’s procedures. They compared his methods to standard technical manual requirements. They analyzed the parts usage, the labor hours, the maintenance costs.

The analysis showed that Milk Wagon consumed more parts than other B7s. The preventive replacement strategy required more spark plugs, more hydraulic seals, more oil filters, more fuel pumps than aircraft maintained by reactive methods. The labor hours were also higher.

Orloski and his crew spent more time on inspections and maintenance than other ground crews, but the bomber flew more missions, completed more sorties, delivered more bombs. The return on investment was clear. The extra parts and extra labor produced an aircraft that never failed.

An aircraft that was always available, an aircraft that contributed more to the war effort than any other B7 in the group. The engineering staff recommended that other crew chiefs adopt Orloski’s methods. Some did. They increased inspection frequency. They replaced parts earlier. They tracked components more carefully. Their aircraft reliability improved. Abort rates decreased.

Mission completion rates increased, but none achieved what Orloki achieved with Milk Wagon. None maintained zero aborts over extended periods. None reached 100 missions without mechanical failure. The combination of Olok’s skill, his crew’s dedication, and the flight crews careful operation created a unique result. By April 1945, Milk Wagon had become more than an aircraft.

The bomber represented what was possible when maintenance excellence met operational excellence. When ground crews and flight crews worked toward the same goal. When individuals refused to accept that failure was inevitable. The cowpainted fortress with the ridiculous name proved that aircraft did not have to fail. That mechanical reliability was achievable.

That one mechanic’s obsessive attention to detail could overcome the chaos and complexity of bomber operations. 129 consecutive missions without a single mechanical abort. The record stood alone in the Eighth Air Force in the entire European theater, possibly in the entire war. Other B7s flew more total missions. Some fortresses accumulated over 140 sorties, but those aircraft aborted regularly.

Mechanical failures forced them to turn back. They did not maintain uninterrupted streaks. They did not achieve perfect reliability. Milkwagon did. The achievement was documented in official 447th bomb group records, mission logs, maintenance reports, engineering summaries. The statistics were verified. The record was confirmed.

129 missions, zero mechanical aborts, verified by multiple sources. Robert E. Orloki’s Bronze Star citation recognized his achievement. The medal acknowledged his exceptionally meritorious service, his skill, his dedication, his contribution to the war effort. But the citation could not capture the full scope of what he accomplished.

He proved that aircraft reliability was not a matter of luck. It was a matter of maintenance, proper maintenance, preventive maintenance, obsessive maintenance. The kind of maintenance that most organizations could not sustain, but that produced results no other approach could match. After the war, Orloki returned to civilian life. He worked as a mechanic in Pennsylvania.

He maintained civilian aircraft, automobiles, industrial equipment. He applied the same principles he learned during the war. Preventive maintenance, early part replacement, detailed recordkeeping. The equipment he maintained rarely failed. He died in 2004 at age 86. His obituary mentioned his military service, his bronze star, his work on the milk wagon, but the obituary could not convey the significance of what he achieved during 13 months at RAF Rattlesen.

His son remembered his father as a quiet man, humble, unassuming, someone who did his job without seeking recognition. Someone who took pride in his work but did not boast about his achievements. Someone who believed that doing a job right was its own reward. That attitude defined his wartime service. He maintained an aircraft because that was his assignment.

He performed preventive maintenance because that was what the job required. He achieved a perfect reliability record because he refused to accept anything less. He never sought fame. He never promoted his achievement. He simply did his work. But his work saved lives. Every mission Milk Wagon completed was a mission where 10 airmen flew in an aircraft they could trust.

Every sorty was a sorty where the crew focused on fighting the war rather than worrying about mechanical failures. Every bombing run was a run where the bomber stayed in formation and delivered its weapons on target. And over 129 missions, that reliability contributed to Allied victory.

Each successful mission weakened Germany’s ability to wage war. Each bomb load delivered struck at enemy infrastructure. Each sordy that did not abort meant maximum bomber strength over target. Orlosk’s work enabled combat effectiveness. His maintenance philosophy translated directly into military success. The Milk Wagon was scrapped in December 1945.

The aircraft no longer exists. No museum preserved it. No organization saved it. The most reliable bomber in the Eighth Air Force was cut apart and melted down 6 months after the war ended. But the record remains. 129 consecutive missions without a mechanical abort. Achieved by a B17G Flying Fortress named Milk Wagon, maintained by Technical Sergeant Robert E. Orloski and his ground crew.

An achievement that has never been matched. A standard of reliability that stands as a testament to what skilled maintenance can accomplish. If this story moved you the way it moved us, do me a favor, hit that like button. Every single like tells YouTube to show this story to more people.

Hit subscribe and turn on notifications. We’re rescuing forgotten stories from dusty archives every single day. Stories about ground crew mechanics who kept aircraft flying through obsessive attention to detail. Real people, real heroism. Drop a comment right now and tell us where you’re watching from.

Are you watching from the United States, United Kingdom, Canada, Australia? Our community stretches across the entire world. You’re not just a viewer. You’re part of keeping these memories alive. Tell us your location. Tell us if someone in your family served. Just let us know you’re here. Thank you for watching and thank you for making sure Robert E. Ori doesn’t disappear into silence.

These men deserve to be remembered, and you’re helping make that

News

Inside Willow Run Night Shift: How 4,000 Black Workers Built B-24 Sections in Secret Hangar DT

At 11:47 p.m. on February 14th, 1943, the night shift bell rang across Willow Run. The sound cut through frozen…

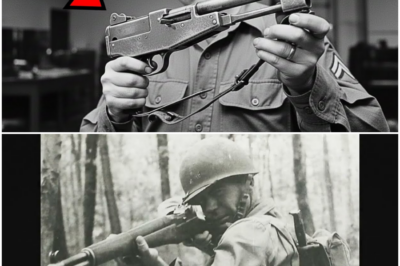

The $16 Gun America Never Took Seriously — Until It Outlived Them All DT

The $16 gun America never took seriously until it outlived them all. December 24th, 1944. Bastonia, Belgium. The frozen forest…

Inside Seneca Shipyards: How 6,700 Farmhands Built 157 LSTs in 18 Months — Carried Patton DT

At 0514 a.m. on April 22nd, 1942, the first shift arrived at a construction site that didn’t exist three months…

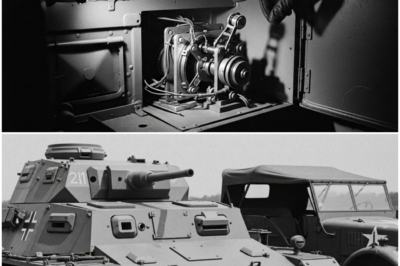

German Engineers Opened a Half-Track and Found America’s Secret DT

March 18th, 1944, near the shattered outskirts of Anzio, Italy, a German recovery unit dragged an intact American halftrack into…

They Called the Angle Impossible — Until His Rifle Cleared 34 Italians From the Ridge DT

At 11:47 a.m. on October 23rd, 1942, Corporal Daniel Danny Kak pressed his cheek against the stock of his Springfield…

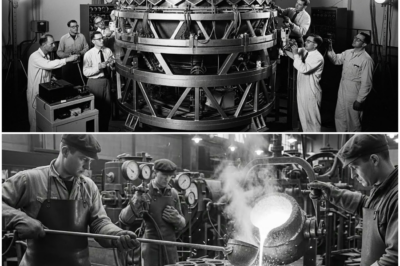

The Trinity Gadget’s Secret: How 32 Explosive Lenses Changed WWII DT

July 13th, 1945. Late evening, Macdonald Ranchhouse, New Mexico. George Kistakowski kneels on the wooden floor, his hands trembling, not…

End of content

No more pages to load