The chemist stands in the Scopa plant on a cold morning in March 1943, watching the polymerization tanks bubble and hiss as they transform coal and limestone into something that resembles rubber. Barely resembles it, he would admit in private. The booners coming off the production line that day would go into tires for Vermach trucks, for Luftvafa bombers, for the panzas grinding eastward through mud that swallowed machines whole. He knows the numbers.

He’s always known the numbers. And the numbers don’t work. They’ve never worked. By this point in the war, they never will. What he couldn’t know, what none of them could know, was that they were trying to solve a problem that had become mathematically impossible. Not difficult, not challenging, impossible.

The arithmetic was brutal and simple, and no amount of German engineering could change it. But to understand how this moment came to pass, how an entire military machine could be brought to its knees by something as mundane as rubber, we need to go back to before the war to a Germany cut off from the world and desperately trying to build an empire on coal and chemistry.

In 1933, when Hitler took power, Germany imported nearly 90% of its rubber from foreign sources, mainly from British and Dutch colonies in Southeast Asia. Rubber plantations in Malaya and the Dutch East Indies supplied over 95% of the world’s natural rubber. All of it controlled by powers that would become Germany’s enemies. Every tire, every gasket, every seal, every insulated wire in the German military depended on rubber that came from places Germany could never reach once war began.

The Nazi leadership understood this vulnerability with unusual clarity. They had lived through the First World War when the British blockade had strangled Germany’s access to raw materials and contributed to the empire’s collapse. Hitler himself referenced this experience repeatedly, the spectre of starvation and material deprivation haunting his strategic thinking.

In his 1936 memorandum on the 4-year plan, he wrote with characteristic bluntness about synthetic rubber production, dismissing cost concerns entirely and demanding immediate mass production. It was, he declared, better to produce expensive tires in Germany than to have no tires at all. The chemical giant Eig Farbin had been working on synthetic rubber since the 1920s.

Their scientists building on decades of polymer research had developed a family of synthetic rubbers they called buuna the name derived from butadene and natrium the German word for sodium which served as a catalyst in early formulations. By 1935 they had created buna as c-olymer of styrene and butadian that could in theory replace natural rubber in most applications in theory.

The first industrial plant began construction at Shkapau in Saxony in April 1936, designed to produce 30,000 tons of buuna annually. A second plant at Hell’s near Mal was planned for 15,000 tons. These were ambitious numbers, but they fell desperately short of Germany’s actual needs. By 1940, Farbin’s internal calculations estimated that the German economic sphere would require 300,000 tons of rubber annually just to maintain military and essential civilian operations. 300,000 tons.

To meet that target, they would need synthetic rubber production at a scale that approached 120,000 to 150,000 tons per year, supplemented by natural rubber imports and stockpiled reserves. Construction of the Buna plants was slow, far slower than the optimistic timetable suggested. The complex chemistry required specialized equipment, specialized workers, and above all, time.

The Scopa plant didn’t begin commercial production until March 1937. By 1939, as Germany invaded Poland, domestic synthetic rubber production was barely a trickle, somewhere around 30,000 tons that year, perhaps 40,000. Not nearly enough. So where did the rubber come from in those early war years? The answer reveals the fragility of the entire German strategic position.

First came captured stockpiles. When the Vermacht swept through Poland, France, Belgium, Holland, and Norway in 1939 and 1940. They seized the national rubber reserves of each conquered nation. These were finite supplies measured in thousands of tons, not the hundreds of thousands that would be needed. They bought time, but only that.

Second came the Molotov ribbon pact. That cynical arrangement between Nazi Germany and Stalin’s Soviet Union that carved up Eastern Europe and crucially for Germany, opened a supply line to the east. Between 1939 and 1941, the Soviets shipped massive quantities of raw materials to Germany, including rubber imported from India and elsewhere, totaling thousands of tons.

Without these Soviet deliveries, German planners later acknowledged Operation Barbarasa would have been impossible to launch. By October 1940, German rubber stocks had fallen to just 1,400 tons, 2 weeks of military consumption in a mobile war. The Soviets kept the Germanwar machine fueled with the very materials that would later be used to invade them.

Third came the blockade runners. German vessels and submarines attempted to slip through the British naval blockade to bring rubber from Southeast Asia, from Japan, from anywhere they could find it. These operations were dangerous, slow, and yielded only marginal amounts. A few thousand tons across the entire war, never enough to matter strategically.

By 1941, German synthetic rubber production had reached 70,000 tons annually, still far below requirements. When Operation Barbarasa launched in June 1941, it severed the Soviet supply line overnight. Suddenly, Germany was entirely dependent on its synthetic production, whatever could be squeezed from occupied territories and whatever the blockade runners could bring through.

The situation was manageable, barely, as long as the synthetic plants kept running, and as long as German forces continued to capture new territories with their own rubber stocks. The chemists at Shupal and Huz worked frantically to increase production. By 1942, the Hull’s plant was producing 50,000 tons of booners annually.

Combined with Scopa and the other facilities, Germany’s total synthetic rubber output reached somewhere close to 100,000 tons in 1943, the peak year, 100,000 tons. It sounds impressive. It was impressive. a remarkable achievement of industrial chemistry and engineering and it was nowhere near enough. Here’s where the mathematics became impossible where the numbers turned into a wall that no amount of German ingenuity could breach.

Germany needed 300,000 tons of rubber annually to sustain its war effort. Let’s break down where that rubber had to come from. In 1943, domestic synthetic production, 100,000 tons at absolute maximum, assuming every plant ran at full capacity, which they rarely did due to raw material shortages, equipment failures, and the increasing weight of Allied bombing.

Natural rubber imports negligible. By 1943, Allied naval superiority had made blockade running nearly suicidal. Japanese submarines would continue to deliver small amounts until 1945, but we’re talking hundreds of tons, not thousands. A few cargo vessels might slip through. One submarine load might be 5 tons, 10 tons, drops in an ocean of need.

Captured stocks by 1943, Germany controlled most of Europe, but Europe’s rubber stocks had long since been consumed. The eastern front still yielded some captured material as the veh retreated, but these were one-time seizures from specific battles or territories, not sustainable supply lines. Reclaimed rubber.

Germany, like every nation at war, ran massive salvage operations to reclaim rubber from old tires, boots, gaskets, anything that could be melted down and reprocessed. This yielded several thousand tons annually. But reclaimed rubber was lower quality and couldn’t replace fresh rubber in critical applications like aircraft tires or high-pressure seals.

Add it all together. 100,000 tons of synthetic production, perhaps 5 to 10,000 tons from imports and blockade running, maybe 10 to 20,000 tons from salvage and reclaimed material, whatever could be seized from occupied territories. In the best case scenario, Germany had access to perhaps 130,000 to 150,000 tons of rubber in 1943 against a requirement of 300,000 tons.

The gap was 150,000 tons minimum. That gap represented half a million tires that couldn’t be made. It represented thousands of aircraft that couldn’t fly because their tires, their seals, their fuel lines couldn’t be replaced. It represented tanks that sat immobile, trucks that couldn’t move, submarines that couldn’t dive because the rubber components that held them together simply didn’t exist.

The gap was a mathematical certainty of defeat written in the production figures of every rubber plant in the Reich. Let’s put those numbers in human terms in the language of the soldiers who depended on this material. A single Panzerife tank required approximately 200 kg of rubber for its wheels, seals, electrical insulation, and other components.

That’s 200 kg, not including the spare parts needed to keep it running. Germany produced around 8,500 Panzerive tanks in 1943. That’s 1,700 tons of rubber just for new Panzerive production. The Panthers that began rolling off the lines that summer, the Tigers, the assault guns, the halftracks, the endless variety of armored vehicles the Vermachar deployed.

A Luftwaffer bomber, a Junker’s J88, required even more rubber. Its landing gear alone used massive tires capable of handling a loaded weight of 15 tons at landing speeds. The entire aircraft contained hundreds of rubber components, seals in the hydraulic systems, insulation for thousands of meters of electrical wiring, gaskets in the engines, rubber mounts to reduce vibration, fuel line connections, oxygen system seals.

Conservatively, each J88 required 300 to 400 kg of rubber. Germany produced over 3,000 J88s and variants in 1943.That’s at least 900 tons for just one aircraft type. Then there were the trucks. The Opel Blitz, the standard German military truck, used approximately 100 kg of rubber per vehicle, mainly in its six large tires, but also in seals, hoses, and electrical components.

Germany needed tens of thousands of trucks to keep its army supplied. And unlike tanks or aircraft, trucks wore out their tires relatively quickly under the brutal conditions of the Eastern Front, where mud, snow, ice, and rough roads destroyed rubber faster than it could be replaced. A truck might need a complete set of new tires every few thousand km in combat conditions.

Multiply that by the tens of thousands of vehicles in service, and the rubber requirements became staggering, and we haven’t even discussed the soldiers themselves. Each German soldier required approximately 15 kg of rubber for boots, gloves, gas mask seals, raincoats, and other equipment. Multiply that by millions of men under arms.

Then there was the civilian economy, which still needed rubber for essential services, for medical equipment, for industrial machinery, for the thousands small things that kept a society functioning even under wartime conditions. The German quartermaster corps maintained detailed records of rubber consumption and those records tell a story of slow strangulation.

In 1942, the Vermacht received allocations that allowed barely for continued operations. By early 1943, the allocations began to tighten. Units on the eastern front reported tire shortages first tanks rolling on bare metal wheels. Trucks patched together with whatever rubber could be scavenged from wrecked vehicles.

Aircraft grounded not because of combat damage but because their tires had worn through and no replacements existed. Colonel General Hines Gudderion, the Panza theorist and inspector of Panza troops, understood the mathematics of rubber better than most. He knew that a mechanized force without tires was simply an expensive collection of metal boxes.

In reports throughout 1943, he emphasized the critical nature of rubber supplies, warning that the Panza forces were being bled white, not by Soviet guns, but by the inability to replace worn out components. The irony was bitter. Germany had developed some of the finest armored vehicles in the world. the Panther and Tiger tanks that terrified Allied crews.

But those magnificent machines sat immo because they lacked rubber parts that cost a few marks to produce. The Luftvafer faced even more immediate problems. Aircraft tires operated under tremendous stress during takeoff and landing, particularly for heavy bombers. A worn tire didn’t just ground an aircraft. It could cause a catastrophic crash on landing, destroying the plane and killing its crew.

By mid 1943, Luftvatha maintenance officers were performing desperate triage, pulling tires from damaged aircraft to keep operational planes flying, retreading tires far beyond their safe lifespan, mixing natural and synthetic rubber in repairs that reduced performance but kept wheels turning. Lieutenant Colonel Helmet Felme, a logistics officer with Luft Flatter 4 on the Eastern Front, later described the rubber shortage as one of the most demoralizing factors for air crew morale.

Pilots who survived combat missions only to find their aircraft grounded by tire failures felt betrayed by their own supply system. The joke became darkly common. We can outfly the Soviets, but we can’t out tire them. The Allied planners knew about Germany’s rubber vulnerability. British intelligence through signals, intercepts, and agent reports had pieced together the outline of Germany’s synthetic rubber industry.

By 1942, the synthetic rubber plants became priority targets, particularly after the Casablanca conference in January 1943, when Allied leaders approved the combined bomber offensive with specific target lists. Synthetic rubber production was explicitly identified as a critical bottleneck in the German war economy.

On June 22nd, 1943, the 8th Air Force launched a massive daylight raid against the Hull synthetic rubber plant near Ma. Over 200 B17 flying fortresses were dispatched to the target, fighting through intense fighter opposition and losing several aircraft to German interceptors and flack. Despite 4/10 to 6/10 cloud cover, the American bombarders scored direct hits on the aiming point.

1560 bombs fell on the Holes complex in a concentrated strike that lasted less than 30 minutes. The raid devastated the plant. Production stopped completely for 3 months. 186 workers were killed. 752 wounded. The complex polymerization equipment, which had taken years to build and calibrate, was smashed.

Some sections of the plant were simply gone, reduced to rubble and twisted steel. When German engineers surveyed the damage, they estimated it would take months to restore even partial production. The impact on Germany’s rubber supply was immediate and catastrophic. Hooves had beenproducing 50,000 tons of bonass annually, nearly half of Germany’s total synthetic rubber output.

Its destruction created an instant shortfall of 4,000 tons per month. 4,000 tons that Vemarked Quartermasters had already allocated to units across Europe and the Eastern Front. Those allocations simply evaporated. Shia’s armament’s ministry, which had taken control of most war production by this point, moved with characteristic efficiency to disperse rubber stockpiles and rush repairs to Hulls.

Forced labor from concentration camps was brought in to clear rubble and rebuild production lines. By late 1943, the Holes plant had resumed partial operations, though it never again reached its pre-rade capacity. But the damage was done. The 3-month production gap created a cascading shortage that rippled through the entire German military for the rest of the war.

The Allies didn’t stop with hulls. Scopal, the other major synthetic rubber plant, became a regular target. The massive Luna chemical complex, which produced both synthetic fuel and the raw materials for rubber production, was attacked repeatedly starting in May 1944. Each raid damaged not just the immediate target, but the entire integrated chemical infrastructure that supported synthetic rubber production.

A plant that made styrene gets hit and suddenly three different rubber plants downstream have no feed stock. A power station gets destroyed and the energyintensive polymerization process grinds to a halt. By late 1944, German synthetic rubber production had collapsed to a fraction of its 1943 peak.

Some accounts suggest production fell below 50,000 tons annually, perhaps as low as 30,000 tons by early 1945. The mathematical impossibility had become a physical reality. There simply wasn’t enough rubber to go around. The consequences played out on every front. In Normandy in June 1944, Panza divisions attempting to counterattack the Allied beach head found themselves immobilized not by Allied firepower, but by mechanical failures caused by worn out rubber parts.

Seals failed in tank transmissions. Electrical systems shortcircuited when insulation wore through. Tire failures left vehicles stranded. Field Marshal Irwin RML, commanding Army Group B in France, reported to Berlin that his forces were bleeding to death from lack of replacement parts, particularly rubber components.

On the Eastern front, where distances were measured in thousands of kilometers and roads often meant mug tracks that destroyed equipment, the rubber shortage became existential. The great Soviet offensives of 1944, Operation Bagration in Bellarus and the Vistula Odor offensive succeeded in part because German mechanized forces lacked the mobility to respond.

Panza divisions that should have been racing to plug gaps in the line instead crawled forward on improvised wheels or sat immo waiting for parts that never came. The Luftvafer’s decline from 1943 onward is often attributed to pilot losses, fuel shortages, and Allied air superiority. All true, but the rubber shortage played its part.

Every aircraft grounded by tire problems was one less machine that could contest Allied bombers, one less fighter that could strafe Soviet positions, one less transport that could supply encircled troops. The cumulative effect of thousands of small failures added up to a force that couldn’t operate at the tempo modern warfare demanded.

Lieutenant Vera Eisenbach, a Panza officer with the 11th Panza Division, later wrote in his memoir about the surreal experience of abandoning perfectly functional tanks during the retreat from the Soviet Union in 1944 because they lacked the rubber seals needed to keep their engines running. “We had fuel,” he wrote. “We had ammunition.

We had crews ready to fight. What we didn’t have were a hundred small rubber parts that held the machine together. And without those parts, 50 tons of German steel became 50 tons of scrap. The German high command tried everything to bridge the rubber gap. Reclamation programs became mandatory with severe penalties for units that didn’t recover rubber from destroyed vehicles.

Research programs explored alternative materials, compressed paper, treated fabrics, even processed plant fibers. Some of these alternatives worked for low stress applications. None could replace rubber in the critical uses that mattered most. There was talk briefly of a massive synthetic rubber expansion program, new plants that would triple production.

The plans were drawn up, sites were selected. But by 1943, Germany lacked the resources to build such facilities. Every ton of steel, every cubic meter of concrete, every skilled worker was already committed to other critical projects. The Reich was trying to fight a multiffront war while also building wonder weapons, increasing aircraft production, maintaining submarine construction, and holding together an empire that stretched from the Atlantic to the Caucuses. There was nothing leftfor rubber plants that would take years

to build and might be bombed to rubble before they ever produced a single tire. And even if they had built new plants, there was the raw material problem. Synthetic rubber required butadene and styrene which in turn required petroleum products or coal processing. Germany’s synthetic fuel industry was itself under immense strain.

Barely able to produce enough gasoline and diesel to keep the Luftvafa and Panza forces operational. Diverting coal and petroleum to rubber production meant cutting fuel production. It was a zero sum game where every choice meant losing somewhere else. The Japanese tried to help. IG Farbin had shared its buuna technology with Japanese chemical companies before the war and Japan operated several synthetic rubber plants of its own.

But Japan faced its own rubber crisis, its own shortages of raw materials and production capacity. What little they could spare was shipped by submarine in tiny quantities. 5 tons here, 10 tons there, drops in an ocean. Some natural rubber did reach Germany through neutral countries like Turkey and Spain. smuggled through Baantine commercial arrangements that cost far more than the rubber was worth.

Some came from occupied territories in Eastern Europe that had small rubber plantations or stockpiles. But these sources together provided perhaps 5% of Germany’s needs, 5%. The mathematics of the rubber crisis extended beyond simple supply and demand. It was embedded in the fundamental strategic miscalculation of the entire German war plan.

Hitler and his generals had designed a military doctrine based on rapid mechanized warfare on tanks and trucks and aircraft moving at speeds that required massive amounts of rubber. They had built an army that depended on mobility, then found themselves unable to provide the one material that mobility required above all others.

Consider the Eastern Front in 1943. The Vermacht held a front line that stretched more than 2,000 km from the Arctic to the Black Sea. Defending such a line required mobility, the ability to shift reserves rapidly to threatened sectors, to concentrate forces for counterattacks, to withdraw before being encircled. Every one of those movements required vehicles, and every vehicle required rubber.

When the rubber ran out, mobility died, and when mobility died, the German position became indefensible. The Soviet Union, by contrast, received massive shipments of rubber from the United States and Britain through lend lease. In the first months after Operation Barbarasa, Britain alone shipped 22,000 tons of rubber to the Soviet Union.

American synthetic rubber production, which had been minimal before the war, expanded to over 700,000 tons by 1944. Some of that rubber went to Soviet forces in the form of tires, boots, and other finished goods. The Red Army fought on American rubber while the Vermacht ground to a halt for lack of it.

There’s a moment that captures the absurdity and tragedy of Germany’s rubber crisis. In April 1945, as Soviet forces closed in on Berlin, a German tank crew abandoned their Panther tank, one of the most sophisticated armored vehicles of the war, mounting a powerful 75 mm gun equipped with excellent optics and protected by sloped armor that could deflect most Allied shells.

They abandoned it not because it was damaged by enemy fire, but because a rubber seal in the cooling system had failed, and without that seal, the engine would overheat and seize within minutes of operation. A 10mark rubber part immobilized a tank that had cost hundreds of thousands of Reichs marks to build.

That Panther sat there intact and armed while Soviet T34s rolled past it into the city. The irony would have been amusing if it wasn’t so representative of Germany’s entire late war situation. They had the technical knowledge, the manufacturing capability, the skilled workers to build weapons that were in many ways superior to Allied equipment.

What they didn’t have, what they could never have after 1943 was enough rubber to keep those weapons operational. By the time Germany surrendered in May 1945, synthetic rubber production had effectively ceased. The plants were bombed, captured, or out of raw materials. The stockpiles were exhausted.

Vehicles across Germany sat immo, their rubber components worn beyond use. In the final battles for Berlin, German forces often fought on foot because they lacked the tires to move their remaining vehicles. After the war, Allied intelligence teams surveyed the German synthetic rubber industry extensively. The United States strategic bombing survey produced detailed reports on the effectiveness of attacks against rubber production.

Their conclusion was unambiguous. The destruction of Germany’s synthetic rubber industry had been one of the most effective elements of the bombing campaign. More effective, they argued, than attacks on ballbearing plants or aircraft factories because rubber couldn’t be stockpiled aseffectively and its absence paralyzed the entire military machine.

Albert Spear, Hitler’s armament’s minister, was even more direct in his post-war testimony. He told Allied interrogators that the May 1944 initiation of sustained attacks on synthetic fuel and rubber production had been the moment Germany lost the war economically. The enemy, Spear said, has struck us at one of our weakest points.

If they persist at it this time, we will soon no longer have any fuel production worth mentioning. The same logic applied to rubber. Once the Allies identified the vulnerability and attacked it systematically, there was no defense, no alternative, no way to bridge the gap. The deeper lesson of Germany’s rubber crisis goes beyond logistics and chemistry.

It reveals the fundamental constraint that geography and resources impose on military power. Germany entered the war dependent on materials it couldn’t produce domestically and couldn’t access through trade once hostilities began. All the German engineering skill, all the chemical innovation that created synthetic rubber, all the industrial effort that built the Buna plants, none of it could change the basic arithmetic.

300,000 tons needed, 150,000 tons available at best. And that gap represented the difference between a mobile army and an immobilized one. There’s a calculation that German logistics officers made throughout the war. a simple equation that determined how many kilometers a Punza division could advance before its rubber wore out.

They called it the tire radius, the distance from supply bases to the front line beyond which the rubber needed to replace worn tires exceeded the rubber needed to maintain the advance. Once you crossed that radius, every kilometer forward made your position weaker, not stronger. By 1943, Germany had crossed that radius everywhere.

On the Eastern front in Italy, eventually in France, their armies were advancing or defending beyond the sustainable distance from rubber production. And unlike fuel or ammunition, which could be rushed forward in concentrated bursts, rubberware was constant, grinding, inevitable. Every kilometer driven wore down tires.

Every mission flown degraded aircraft landing gear. Every day in the field deteriorated the rubber seals and gaskets that held machinery together. There was no surge capacity, no reserve that could be drawn down in emergencies. There was only the steady mathematical certainty that the rubber was running out.

The chemist at Scopa, watching his polymerization tanks in March 1943, probably didn’t think in these grand strategic terms. He thought about yields and purity, about the quality of the bunas his plant was producing, about whether this batch would meet the specifications for aircraft tires or if it would have to be downgraded to truck tires or industrial belts.

But on some level, he must have known. Every chemist in the German synthetic rubber program knew. They knew the numbers, knew the requirements, knew what their plants could and couldn’t produce. They knew the gap. And that knowledge must have been crushing to work with such dedication to solve such complex technical problems, to achieve what was genuinely a remarkable feat of chemical engineering, and to know that it wasn’t enough, that it could never be enough, that the arithmetic of rubber production had doomed the entire enterprise before

it even began. They were solving the wrong problem. The question wasn’t how to make synthetic rubber more efficiently or how to increase yields from the polymerization process. The question was whether a nation without access to natural rubber could sustain a modern mechanized war. And the answer written in production figures and consumption statistics and the mathematics of supply and demand was no.

In the end, Germany’s rubber crisis wasn’t just unsolvable by 1943. It had been unsolvable from the beginning. From the moment Hitler decided to wage war against nations that controlled the world’s rubber supplies. The synthetic rubber program delayed the inevitable, bought time for early victories, allowed the Vermacht to project power across Europe for a few years, but it was always a temporary solution to a permanent problem, a chemical workaround for a strategic impossibility.

The numbers never lied. 300,000 tons needed, 150,000 tons available. The difference was measured in immobilized tanks, grounded aircraft, and an army that had built its doctrine on mobility, watching that mobility drain away, one worn out tire at a time, until nothing remained but the stark arithmetic of defeat.

News

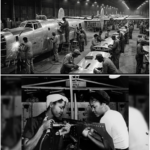

Inside Willow Run Night Shift: How 4,000 Black Workers Built B-24 Sections in Secret Hangar DT

At 11:47 p.m. on February 14th, 1943, the night shift bell rang across Willow Run. The sound cut through frozen…

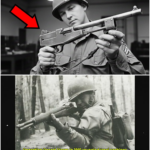

The $16 Gun America Never Took Seriously — Until It Outlived Them All DT

The $16 gun America never took seriously until it outlived them all. December 24th, 1944. Bastonia, Belgium. The frozen forest…

Inside Seneca Shipyards: How 6,700 Farmhands Built 157 LSTs in 18 Months — Carried Patton DT

At 0514 a.m. on April 22nd, 1942, the first shift arrived at a construction site that didn’t exist three months…

German Engineers Opened a Half-Track and Found America’s Secret DT

March 18th, 1944, near the shattered outskirts of Anzio, Italy, a German recovery unit dragged an intact American halftrack into…

They Called the Angle Impossible — Until His Rifle Cleared 34 Italians From the Ridge DT

At 11:47 a.m. on October 23rd, 1942, Corporal Daniel Danny Kak pressed his cheek against the stock of his Springfield…

The Trinity Gadget’s Secret: How 32 Explosive Lenses Changed WWII DT

July 13th, 1945. Late evening, Macdonald Ranchhouse, New Mexico. George Kistakowski kneels on the wooden floor, his hands trembling, not…

End of content

No more pages to load