February 14th, 1943. 30,000 ft above the Ruar Valley, Germany. 11:47 hours, Hedman Klaus Dietrich eases his Messid BF 109 into a lazy barrel roll. Cold morning sun glinting off his canopy. Below a formation of American B7 flying fortresses lumber toward the industrial heart of the Reichike cattle to slaughter.

He toggles his radio, voice dripping with contempt. Look at them, boys. The flying coffins, fat, slow, fragile. Their brownings cannot reach us here, and when they turn for home, their fighter escort abandons them like frightened children. These Amos think aluminum and audacity will win this war. Today, we teach them the price of arrogance.

His wingman laughs over the static. The Germans had a nickname for the B7s in those early months. Flyen scourge flying coffins. Dietrich had personally sent three to Earth in flames. He checks his ammunition counter full load. This would be easy. What he didn’t know was that 8,000 mi away in a freezing Omaha maintenance hanger lit only by work lamps and cigarette embers, a 23-year-old mechanic named Jack Silva had just solved the problem that would turn America’s bombers from vulnerable giants into the unstoppable hammer of God. Before we dive in, make sure you’re

subscribed. Every week we uncover the stories the world forgot. The Boeing B7 Flying Fortress was never supposed to be a coffin. It was supposed to be a statement. When the prototype rolled out in 1935, it bristled with so many defensive machine guns that a reporter coined the name on site.

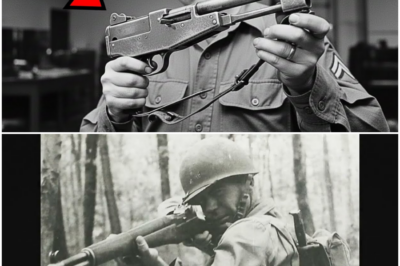

By 1943, the Geomodal carried 13 Browning and M2.5 Oaliber heavy machine guns. 132 in the chin turret, two in the top turret, two in the ball turret beneath the fuselage, two waist guns, two in the tail, one in the radio compartment, and two cheek guns flanking the nose. Each gun cycled 750 to 850 rounds per minute.

At maximum rate of fire, a single B7 could theoretically throw 10,500 bullets into the sky every 60 seconds. The convergence zone, the lethal cone of overlapping fire where multiple guns tracked the same target extended roughly 400 yd in a sphere around the aircraft. Step into that zone and you stepped into a hurricane of/2-in lead traveling 2,900 ft pers.

But theory and reality were separated by a chasm of frozen oil, jammed receivers, and dead gunners. The Browning M2 was a masterpiece of engineering, a recoperated aircooled weapon that could punch through engine blocks and cockpit armor. It had won wars in the trenches and on the wings of fighters. But at 30,000 ft, where temperatures plunged to 40 below zero and oxygen thinned to nothing, the M2 became temperamental.

Oil congealed into sludge, rounds misfired or failed to feed. Gunners, hypoxic and numb inside electrically heated suits that barely worked, wrestled with weapons that choked and stuttered when their lives depended on continuous fire. A fortress with 13 guns on paper, often limped home with half of them silent, frozen, or blown apart by cannon shells that punched through gaps the guns should have defended. The early missions over Europe were blood baths dressed in statistics.

On October 14th, 1943, during the second raid on Schwinfort’s ballbearing factories, the Eighth Air Force dispatched 291 bombers. 60 did not return. 60. Another 140 came back so shredded by flack and fighter cannon that they would never fly again. Entire formations were erased from the sky. The Luftvafa had learned to exploit the fortress’s blind spots, head-on attacks from 12:00 high, where only the chin, turret, and cheek guns could respond, and those guns often froze first.

German pilots called it frontal langritha, frontal assault hand. They executed it with surgical precision. Dietrich and men like him would climb above the bomber stream, flip inverted, and dive straight down the throat of the formation. 20 mm cannon shells, ripping through cockpits, flight decks, and fuel tanks.

By the time a bombers’s gunners could react, the Messmmet was already gone, pulling up hard and looping back for another pass. The doctrine emerged from desperation. Major General Curtis Lame, a man whose face looked carved from Nebraska granite and whose voice carried the weight of inevitable mathematics, gathered his squadron commanders in a freezing Quanet hut at Thorp Abbotts in November 1,943.

He unrolled reconnaissance photos across a table scarred by cigarette burns. Gentlemen, the Luftvafa is killing us because we are predictable. We fly straight, we fly level, we bunch up for mutual protection, and we die in neat rows. Starting tomorrow, we change everything. His plan was brutal in its simplicity.

Tighten the formations until wing tips nearly kissed, making it impossible for fighters to slip between bombers. Assign each aircraft a precise position so that interlocking fields of fire created a continuous wall of lead and drill gunners until they could track a target through frostblind goggles, hypoxia, and terror.

Lame’s voice dropped to a growl. If your guns freeze, you die. If your discipline breaks, you die. If you give the enemy one second of hesitation, you die. There is no middle ground in this war. Make your weapons work or make peace with God. But discipline couldn’t unfreeze oil. Training couldn’t unjam a receiver choked with ice crystals.

The B7 crews needed a miracle, and they got Jack Silva instead. Silva was not supposed to be anyone important. He was a second generation Portuguese immigrant from Fall River, Massachusetts, who had spent 3 years before the war keeping fishing boats running on spit and profanity.

The Army Air Forces had assigned him to a maintenance depot in Omaha, Nebraska, where his official job involved cleaning spark plugs and torquing bolts according to manuals written by men who had never felt frostbite through sheepkin gloves. But Silva had a gift. He could listen to an engine and diagnose its soul. He could feel a misalignment through a wrench handle.

And on a January night in 1943, while the rest of his shift huddled around a barrel fire Silva, stood alone in a hangar bay, staring at a Browning M2 that had come back from England, packed in cosmoline and failure. The gun had frozen mid-bururst over Wilhelm’s coffin. The waste gunner who’d manned it took a 20 mm shell through the chest.

3 seconds later, Silva Field stripped the weapon under a work lamp that buzzed like a trapped hornet. He checked head space, timing, gasport alignment. Everything was perfect. Everything was wrong. He cycled the action manually, smooth. He loaded a belt of dummy rounds, fed perfectly. He took the gun outside into the Nebraska cold 18°.

Balmy compared to altitude danned, fired a test burst into a dirt burm. 20 rounds, flawless. He brought it back inside, let it warm up, then dunked the entire receiver assembly into a barrel of ice water. waited 5 minutes, pulled it out, locked it into a test mount, and squeezed the trigger. Click. Nothing.

The firing pin struck home, but the round didn’t fire. Silva cycled the action. The spent cartridge ejected, but the fresh round failed to chamber completely. He pulled the belt free and examined the cartridge under a magnifying glass. There, a microscopic film of ice on the primer. Not enough to see, but enough to insulate the firing pin strike.

And there the feed pulse slick with oil that had thickened just enough to slow the mechanism by a fraction of a second. At ground level, it didn’t matter. At altitude, where every mechanical tolerance shrank and every lubricant thickened, it was the difference between life and death.

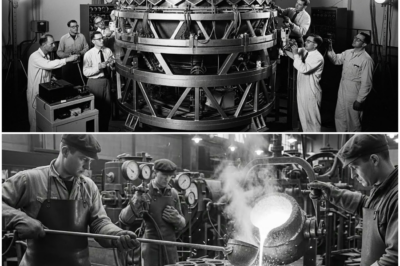

Silva spent 4 days testing oils, greases, and solvents. He tried everything in the supply catalog and half the compounds that weren’t. He borrowed a refrigerated meat locker from a local butcher and turned it into a makeshift altitude chamber running guns at 20 below until his fingers cracked and bled. Finally, he found it.

A lightweight synthetic lubricant designed for Arctic convoy engines mixed 3:1 with pure graphite powder. It stayed fluid at 50 below. It didn’t gum up. It didn’t attract moisture. And it cost 97 cents per quart. 97 cents. Sylve wrote up his findings in a two-page report that should have vanished into a filing cabinet. Instead, it landed on the desk of Lieutenant Colonel Harold Bowman, a logistics officer who had lost a younger brother over Bremen and who read every maintenance report like scripture. Bowman made three phone calls.

One week later, Silva’s formula was in mass production. 2 weeks after that, every B7 maintenance crew in England received a technical bulletin, TB43012, cold weather lubrication protocol for an M2 aircraft machine guns. 3 weeks after that, the bulletin became mandatory. And 4 weeks after that, the Luftvafa started dying in numbers that made their ACES question reality.

The first proof came on March 6th, 1944 over Berlin. Second Lieutenant Robert Harper, ball turret gunner on a B17 named Maiden America, hung suspended in his spare turret like a fetus in a mechanical womb. The ball turret was a plexiglass sphere bolted to the underside of the fuselage barely large enough for a man to curl into a fetal position with two 50 cals between his knees. It offered a 360° field of fire and a 360° view of your own death.

Harper was 20 years old. He had been operational for 6 weeks. This was his ninth mission and it was already the worst. The formation had lost its fighter escort over Magda Burke. The P47 Thunderbolts had reached the limit of their range and peeled away, wagging their wings in apology, leaving the bombers naked under a sky full of predators.

Harper counted 16 Fwolf FW190s circling like wolves, their radial engines snarling as they set up for coordinated attacks. His intercom crackled. The pilot’s voice calm as Sunday dinner. Fighters 12:00 level. Everybody stay sharp. The first 190 came in fast and flat. Cannon winking. Harper tracked it through his reflector sight, squeezed the triggers. Both guns roared. The convergence was perfect.

Both streams of tracer fire stitched across the fighter’s nose, and Harper watched pieces of cowling peel away like aluminum confetti. The 190 snap rolled right and Dove smoking Harper didn’t have time to celebrate. Two more were already coming in from 4:00 low. The classic blind spot approach. He rotated the turret, the electric motors whining, and opened fire at 600 yd.

The left gun hammered out 40 rounds. The right gun hammered out 40 rounds. Neither gun faltered. The 50 caliber rounds arked through the thin air and one of the 190s flew directly into the stream. Harper saw the right-wing route explode, saw the fighter tumble away like a broken kite. The intercom was chaos now.

The top turret gunner, Sergeant Paul Chen, was screaming bearings and distances. The tail gunner, Sergeant Eddie Kowalsski, was firing in controlled bursts. His twin guns sounding like a bass drum section gone mad. Harper’s world shrank to the reflector site. the trigger paddles and the endless belt of ammunition feeding into his guns.

Another 190. Another burst. The fighter jked hard, but Harper let it perfectly and walked his fire across the cockpit. The flockwolf’s canopy shattered. Maiden America took hits. Flack had already torn a 3-foot hole in the port wing.

A 20 mm shell punched through the radio compartment, killing the radio operator instantly. Another shell detonated against the number three engine, shredding the cowling and setting the oil cooler on fire. The pilot, Captain James Ridley, feathered the prop and triggered the engine fire suppression. The fire died. The bomber flew on. For 17 minutes, the Luftvafa hammered the formation.

For 17 minutes, the gunners of the 381st Bomb Group fired back with weapons that did not freeze, did not jam, did not fail. Made in America landed at Rididgewell on two engines and fumes. When the crew climbed out, their flight suits were black with hydraulic fluid, blood, and cordite residue. Harper’s hands shook so badly he couldn’t light his own cigarette.

The ground crew chief, Master Sergeant Leon Watts, walked a slow circle around the aircraft, counting holes. He stopped at 214. Then he climbed up to inspect the ball turret guns. Both were still warm, still clean, still ready. Watts ran a finger along the receiver and felt the slick graphite film. He looked at Harper, who was sitting on the tarmac with his head between his knees. “Kid,” Watts said quietly.

“I don’t know what they’re putting in these guns now, but whatever it is, it just saved your life. It wasn’t just the guns. It was the system. It was the training. It was the industrial ecosystem that could absorb Silva S97, fix and scale it across an entire theater in less than a month.

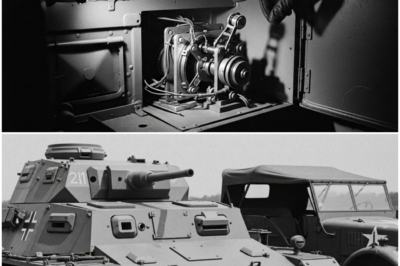

And it was about to get worse for the Luftvafa because while Jack Silva was solving frozen guns in Omaha, Boeing engineers in Seattle were redesigning the Chin turret. The original B17F had a handheld 50 cal in the nose operated by the Bombardier. When he wasn’t busy with the Nordon bomb site, it was better than nothing, barely. The B17G, which began reaching England in September 1943, added a remotely operated chin turret to 50 caliber guns in a powered mount controlled by the Bombardier via a reflector site.

The turret could traverse 90° and elevate 45°, covering the entire frontal arc that had been the fortress’s Achilles heel. Paired with the cheek guns, the G-motal could now put four heavy machine guns on a head-on attacker. Four guns meant 3,000 rounds per minute in the convergence zone. The Luftvafa’s favorite tactic had just become a suicide run. The first G models arrived with teething problems.

The turret motors overheated. The ammunition feeds jammed. Bombarders who were trained to drop bombs and navigate, not dogfight, struggled with the sight picture. But the crews learned they practiced on the ground, rotating the turret through its full range until the motion became instinct.

They learned to fire in short bursts, conserving ammunition and keeping the barrels cool. They learned to aim not at the fighter, but at the point in space where the fighter would be when the bullets arrived. And they learned that the Chin turret, combined with Silva’s lubrication fix, turned the flying fortress into exactly what its name promised, an airborne castle that killed anything foolish enough to approach.

The sound of a B7 under attack became legendary. The deep rhythmic thump thump of the twin 50s in the ball turret. The higher pitched chatter chatter of the waist guns. The staccato pop of the tail guns firing in precise bursts. And over it all the base roar of the chin turret like rolling thunder compressed into mechanical fury.

Luftvafa pilots who survived described it as do summoned the hum wall of sound and led that turned the sky into a death trap. One German pilot Oberloin and Fran Stigler wrote in his diary after a mission in April 1944. We attacked a formation of fortresses today. I fired all my ammunition and hit nothing. The return fire was so intense that I could see the tracers forming a web like the threads of a spider’s nest, but made a fire.

My wingman flew into that web and simply came apart. I do not know how to fight such a thing. It is not a bomber. It is a fortress that flies and shoots in all directions at once. By spring of 1944, the B7’s role had expanded beyond anything its designers had imagined. The logistics behind this expansion defied comprehension.

Every gallon of 100 doctane aviation fuel had to cross the Atlantic in tanker convoys hunted by Ubot. Every spare part, every ammunition belt, every quart of Silva’s synthetic lubricant traveled the same gauntlet. Yet the supplies kept flowing. By March 1944, the Eighth Air Force in England was burning through 6.5 million gallons of aviation fuel per month.

American factories were producing Browning M2 machine guns at a rate of 12,000 per month, more than one every 4 minutes around the clock. Ammunition production had scaled to levels that sounded fictional. 1.5 billion rounds of 50 caliber ammunition in 1944 alone. The math was simple and terrifying. Every B7 carried roughly 11,000 rounds distributed across its defensive guns.

The Eighth Air Force could load every bomber in its inventory, send them on a maximum duration mission where every gunner expended every round and have the entire fleet rearmed within 48 hours. The Germans couldn’t replace pilots in 48 hours. They couldn’t replace experienced pilots at all.

Feldweble Hinrich Mueller had been flying Messersmidt BF-1009 since the Battle of Britain. He had 41 confirmed kills painted beneath his canopy, Braille Spitfires, Hurricanes, P47s, and 17 B7s. In April 1944, he was shot down for the first time over Schweinford. He bailed out at 18,000 ft, landing in a farmer’s field with a broken ankle and secondderee burns across his left arm. The Luftvafa medical cores patched him up and sent him back to his squadron 10 days later.

In that same 10-day period, the Americans had trained, equipped, and deployed 340 new bomber crewmen. Mueller shot down two more B7s in May before a 50 caliber round from a ball turret gunner severed his left leg at the knee. He survived, but his war was over. The American crew that shot him down completed their tour and went home.

Their aircraft was repaired, assigned a new crew, and flying combat missions again within a week. This was the mathematics that broke the Lufafa spine. Not superior tactics, not better aircraft. Pure inexurable replacement rates. For every German pilot killed, the training pipeline produced onetenth of a replacement. For every American bomber shot down, American factories built three more.

For every American airman killed, five more graduated from training schools in Texas, Arizona, and Florida. The Germans were fighting a war of attrition against an enemy that treated attrition the way a man treats a paper cut. Annoying, manageable, ultimately irrelevant. But the Luftvafa was not finished. In desperation, they unleashed weapons that should have changed everything.

The Messormme 262 Schwab Swallow was a technological leap that arrived too late and in too few numbers to matter. Powered by two Junkers Jumo O4 turbo jet engines producing 1,980 lb of thrust each, the Mi262 could reach 540 mph, 150 mph faster than any Allied fighter. It carried for 30 mm MK 108 autoconsins in the nose.

Each shell weighing half a pound and carrying enough high explosive to tear a B7’s wing off with a single hit. In theory, a squadron of Mi262s could slash through a bomber formation like a scythe through wheat, too fast for the defensive guns to track. Too heavily armed to require more than a single pass.

In practice, the Mi262 had an Achilles heel the size of the Brandenburg gate. It was desperately vulnerable during takeoff and landing. The Jumo turbo jets required long smooth runways and nearly 2 minutes of straight level flight to spool up to operational thrust. Allied intelligence identified every MI262 airfield within a week of the first operational sorties.

By October 1944, P-51 Mustangs were loitering over Luftvafa jet bases waiting for the Mi262s to come home. The jets would scream in low and fast, geared down, flaps extended, throttles pulled back. And in that moment, that brief helpless window where speed bled away, and maneuverability vanished, the Mustangs would pounce. Lieutenant Colonel John Mayer of the 352nd Fighter Group described it coldly.

The 262 is the fastest thing in the sky, but it has to land sometime, and when it does, it’s just another target. On November 2nd, 1944, Captain Leonard Kit Carson of the 357th Fighter Group caught an MI262 on final approach to ECM airfield. The German pilot, likely exhausted from a combat sorty, never saw Carson coming.

Carson close to 300 yd and fired a 2-cond burst. 6050 caliber rounds punched through the jet’s left engine, and the Jumo disintegrated in a spray of turbine blades and burning kerosene. The MI262 hit the runway nose first at 200 mph and cartw wheeled through a hanger. Carson didn’t even slow down.

He pulled up, scanned for additional targets, found none, and climbed back to altitude to rejoin his squadron. Postwar records showed that more Mi262s were destroyed on the ground or during takeoff and landing than were ever lost in air-to-air combat. The future of aviation warfare had arrived still, strangled by logistics and patience. The heavy tanks came next. Panther, the Tiger, the King Tiger steel monsters that could shrug off hits from Allied tank guns and return fire with 75 mm and 88 mm cannons that turned Sherman tanks into funeral ps.

On paper, the German armor advantage was overwhelming. On the battlefield, it evaporated under the weight of American air superiority. B7s designed for strategic bombing at high altitude proved surprisingly effective in a role they were never intended for. Tank busting not through direct attack.

Dropping 500lb bombs from 20,000 ft onto a moving tank was a lottery ticket, but through systematic destruction of everything tanks needed to survive. Fuel depots, ammunition dumps, railway marshalling yards, repair facilities, bridge spans. The fortresses didn’t kill tanks, they starved them. Operation Cobra, launched on July 25th, 1944, demonstrated the concept with brutal clarity.

In preparation for the American breakout from Normandy, 1,500 B7s and B-24 Liberators carpet bombed a 5m wide strip of German defensive positions west of St. Lelay. They dropped 4,000 tons of high explosive in less than 90 minutes. The bombs didn’t just destroy the German tanks and artillery. They pulverized the roads, cratered the fields, and turned the Earth itself into an impassible moonscape.

When the American armor rolled forward, they encountered German tank crews wandering in shock, bleeding from ruptured eardrums. Their Panthers and Tigers abandoned because there was literally no ground firm enough to drive on. General Magher Fritz Berline, commander of Panzer Division, reported after the battle, “By noon, nothing was visible but dust and smoke.

My front lines looked like the surface of the moon, and at least 70% of my troops were out of action, dead, wounded, crazed, or numb. All my forward tanks were knocked out, and the roads had ceased to exist. 70% in 90 minutes. The hubot, once the terror of the Atlantic, found themselves hunted by B7s retrofitted for maritime patrol. The radar sets that sprouted from their noses and bellies could detect a surfaced submarine at 20 m.

The depth charges and acoustic homing torpedoes they carried could kill a yubot even through evasive maneuvers. Kapata Lutinet Warner Hank, commander of U515 and one of the Marines top aces wrote in his final patrol log before his capture in April 1944. We can no longer surface during daylight. The American aircraft are everywhere and their radar sees through fog and darkness.

We are blind men being hunted by hawks. Every hour on the surface is borrowed time. Back in England, the maintenance crews worked miracles measured in man-hour in Greece. A B7 returning from a maximum effort mission would land with hundreds of holes, damaged hydraulics engines running rough, and gunners who needed to be physically lifted from their stations because they debotionless in freezing temperatures for 8 hours.

The ground crews mechanics, armorers, sheet metal workers. Electricians would swarm the aircraft like ants on a fallen apple. Engines were pulled and replaced in 6 hours. Hydraulic lines were spliced and pressure tested in three holes were patched with aluminum sheet and rivets, dozens of them, sometimes hundreds.

The guns were pulled, cleaned, inspected, and relubricated with Silva’s formula. Fresh ammunition belts were loaded. Oxygen bottles were refilled. The aircraft was refueled. The tires were checked. The controls were tested. And 20 hours after landing as a flying scrapyard, the B7 was back on the flight line, ready for the next mission.

The pilots joked grimly that you could crash land a fortress in a farmer’s field, and if you came back the next day, the ground crew would have it flying again with parts scavenged from a bicycle and a Ford tractor. It wasn’t far from the truth. Master Sergeant Theodore Teddy Kowalsski, a crew chief with the 91st Bomb Group, once repaired a battle damaged B17 using a section of wingspar from a crashed British Halifax bomber, 30 ft of braided steel cable intended for a barrage balloon, and a hydraulic pump from a captured German halftrack.

The repairs held for 17 more combat missions before the aircraft was finally retired after completing its 100th sorty and sent back to the states as a warbond tour exhibit. The Luftvafa aces, who survived long enough to be interrogated after the war, spoke of the American bomber streams with something close to awe.

Aubberst Johan Steinhoff, a veteran fighter pilot with 176 kills, sat across from American intelligence officers in June 1945 and chose his words carefully. You must understand, we were not defeated by superior courage or superior skill. Your bomber crews were brave, yes, but so were ours. Your fighters were good, but so were ours, especially early in the war.

What defeated us was mathematics. You could afford to lose. We could not. Every mission we flew, we knew that the bombers we shot down would be replaced within days. The crews we killed would be replaced within weeks. But when we lost a pilot, a trained, experienced pilot, he was gone forever.

By 1944, we were sending boys into combat with 40 hours of flight training, and they died within their first three missions. Your boys arrived with 300 hours of training and they kept coming and coming and coming and we simply ran out of time. The scoreboard crescendo came in the final year of the war.

From June 1944 to May 1945, the eighth air force flew 178,000 combat sordies. They dropped 450,000 tons of bombs on targets across Germany and occupied Europe. The B7 flying fortress alone was responsible for half of that tonnage, 225,000 tons delivered in broad daylight in the face of flack and fighters through winter storms and summer haze.

The aircraft that Hedman Dietitrich had mocked as a flying coffin had evolved into something far deadlier. A weapons platform so reliable, so numerous, and so welldefended that the Luftvafa simply stopped trying to stop them. By March 1945, German fighters rarely intercepted bomber formations at all.

The flack kept firing because the guns couldn’t run away. But the pilots, those who remained, had learned that attacking a box formation of B7s was statistically indistinguishable from suicide. The loss ratios told the story in stark numbers. In 1943, the eighth air force lost 4.5% of its bombers per mission and unsustainable rate.

That meant a crew s statistical life expectancy was 22 missions, just under the required 25 mission tours. By mid1944, after Silva’s lubrication fix, after the Chin turret retrofit, after the doctrine and training and logistics had matured into a seamless machine, the loss rate had dropped to 1.9%. By early 1945, it was below 1%. The B7 groups completing their final missions over Germany in April 1945 were losing one bomber per 100 sorties.

The Luftvafa, by contrast, was losing pilots faster than they could be counted. In the first four months of 1945, German fighter losses exceeded 2,000 aircraft. The final operational mission flown by Eighth Air Force B7s occurred on April 25th, 1945. The target was the Kota Armament Works at Pilson, Czechoslovakia.

The 381st Bomb Group flying out of Rididgewell put up 18 aircraft. Made in America, the same fortress that Robert Harper had defended over Berlin 14 months earlier was among them. She had flown 127 combat missions. She had taken more than 800 hits from flack and fighters. She had brought her crews home every single time.

The Pilson mission was a milkrun clear skies, no fighter opposition, moderate flack that burst well below the formation. Harper, now a staff sergeant with a distinguished flying cross and two bronze stars, sat in his ball turret and watched the bombs fall away in a long, graceful arc. He didn’t fire a shot. Nobody did. The war was ending, and everyone knew it.

When Maiden America touched down at Rididgewell for the last time, the crew posed for a photograph in front of her nose. Harper is on the far left, squinting into the late afternoon sun, his flight jacket unzipped, his crush cap pushed back on his head. He looks exhausted and impossibly young. Behind him, the ball turret hangs silent, its twin guns pointed at the ground.

Painted beneath the cockpit are 127 bomb symbols, one for each mission, and 13 small swastikas representing confirmed kills. Ground crew chief Leon Watts stands beside the nose gear, one hand resting on the tire, his expression unreadable. The photographer captured something in that moment. Not triumph exactly, but relief. The kind of relief that comes from surviving something that should have killed you a 100 times over.

Today, AB17G rests on the museum floor of the National Air Force Museum in Dayton, Ohio. Her serial number is 4483575. She never saw combat. She was completed too late and spent her service life as a training aircraft in Texas, but she is mechanically identical to the fortresses that flew over Berlin, Schweinfort, and Pilson. Her ball turret is intact.

Her chin turret is functional, and inside her waist gun positions, mounted on their swivel brackets, are two Browning and M2.5 caliber machine guns, still coated in a thin film of graphite laced synthetic lubricant that cost 97 cents per quart. In 1983, historians conducting interviews for an oral history project tracked down Klaus Dietrich.

He was 71 years old, living quietly in Munich, working as a consultant for Lufanza. When asked about the American bombers, he was silent for a long moment. Then he said in accented but precise English, “We called them flying coffins. We were wrong. We were the ones who died. They kept coming and we could not stop them. I do not think we ever had a chance.” The mechanic’s name was Jack Silva.

He never flew a combat mission. He never fired a shot in anger. He spent the war in Nebraska, freezing his hands in a meat locker, testing gun oils, and filling out maintenance reports. But his 97 cent fix reached across an ocean and changed the math of survival for tens of thousands of young men hanging in gun turrets at 30,000 ft.

It didn’t win the war alone no single innovation ever does. But it was one thread in the vast intricate web of American industrial and logistical might that turned the Boeing B7 flying fortress from a beautiful theory into an unstoppable reality. The sky over Europe belonged to America, not because American planes were faster or more maneuverable or more heavily armed and kept working and could not be stopped by cold or fear or the full desperate fury of the Third Reich.

If you love untold stories from history’s darkest hours, subscribe and join us on the next mission through

News

Inside Willow Run Night Shift: How 4,000 Black Workers Built B-24 Sections in Secret Hangar DT

At 11:47 p.m. on February 14th, 1943, the night shift bell rang across Willow Run. The sound cut through frozen…

The $16 Gun America Never Took Seriously — Until It Outlived Them All DT

The $16 gun America never took seriously until it outlived them all. December 24th, 1944. Bastonia, Belgium. The frozen forest…

Inside Seneca Shipyards: How 6,700 Farmhands Built 157 LSTs in 18 Months — Carried Patton DT

At 0514 a.m. on April 22nd, 1942, the first shift arrived at a construction site that didn’t exist three months…

German Engineers Opened a Half-Track and Found America’s Secret DT

March 18th, 1944, near the shattered outskirts of Anzio, Italy, a German recovery unit dragged an intact American halftrack into…

They Called the Angle Impossible — Until His Rifle Cleared 34 Italians From the Ridge DT

At 11:47 a.m. on October 23rd, 1942, Corporal Daniel Danny Kak pressed his cheek against the stock of his Springfield…

The Trinity Gadget’s Secret: How 32 Explosive Lenses Changed WWII DT

July 13th, 1945. Late evening, Macdonald Ranchhouse, New Mexico. George Kistakowski kneels on the wooden floor, his hands trembling, not…

End of content

No more pages to load