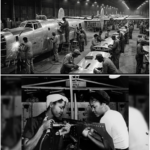

The Corsair Warplanes: A Glimpse into the Final Stages of Assembly in the 1940s

During the tumultuous years of the 1940s, as the world was embroiled in the horrors of World War II, the aviation industry became a vital force in shaping the course of the conflict. Among the most iconic and effective fighter aircraft of the era was the Vought F4U Corsair. With its distinctive gull-wing design and powerful capabilities, the Corsair made a significant impact in both the Pacific and Atlantic theaters of war. However, its legacy goes beyond its combat prowess. The meticulous process of assembling these warplanes, especially in their final stages, serves as a testament to the precision and expertise required to build such formidable machines.

As the Corsair warplanes neared the end of the assembly line, a carefully orchestrated series of tasks ensured that each aircraft was ready for the front lines. The final stages of production, which occurred in factories across the United States, were characterized by minute inspections, the application of finishing touches, and the careful integration of various components that brought the aircraft to life. These last steps were crucial in ensuring that every Corsair was up to the highest standards of performance and reliability.

The Assembly Line: From Start to Finish

The assembly line for the F4U Corsair was a marvel of industrial efficiency. Constructed by Vought, a leading aviation manufacturer, the process involved thousands of workers, including engineers, machinists, assemblers, and inspectors, all playing a role in the creation of the warplane. The Corsair’s design was revolutionary for its time, with its unique inverted gull-wing, which allowed for better ground clearance for its large propeller. This design made the Corsair ideal for carrier-based operations, as it could take off and land on aircraft carriers with relative ease.

The process of building each Corsair involved multiple stages, beginning with the construction of its fuselage, wings, and tail sections. Each part of the aircraft was built separately before being brought together for the final assembly. As the various sections of the plane were assembled, technicians and workers ensured that each part met strict military specifications. The joining of the components was a delicate process that required precision to ensure proper aerodynamics and structural integrity.

The complexity of the assembly line was further emphasized by the necessity for the integration of various mechanical and electrical systems. The Corsair was powered by a Pratt & Whitney R-2800 Double Wasp engine, one of the most powerful piston engines of the era. Ensuring the proper installation of this engine, along with its cooling and fuel systems, was a critical part of the assembly. The workers also had to install the Corsair’s armament systems, which included six .50 caliber Browning M2 machine guns mounted in the wings, as well as the necessary bomb racks and launchers for the aircraft’s ordinance capabilities. The integration of these elements required a high degree of skill and knowledge, as they had to be aligned perfectly to ensure proper functionality.

The Final Stages: Precision and Inspection

As the Corsair neared the end of the assembly line, the focus shifted toward the finishing touches that would bring the aircraft to operational readiness. Every aspect of the plane was subjected to rigorous inspections to ensure that no detail was overlooked. These inspections were often conducted by specialized inspectors who had years of experience and knew exactly what to look for in a plane that was destined for combat.

One of the most important steps during this final phase was the inspection of the aircraft’s wings. The Corsair’s distinctive gull-wing design was both a technical innovation and a complex engineering challenge. Inspectors had to check for any imperfections or weaknesses in the wing structure, as even the smallest flaw could compromise the aircraft’s flight performance. The wings were carefully aligned with the fuselage, and any discrepancies were corrected before the plane could be considered ready for takeoff.

Similarly, the engine installation was scrutinized to ensure optimal performance. The Double Wasp engine, with its enormous power and complexity, had to be calibrated and tested to ensure that it could perform at its peak under the stresses of combat. Technicians would check for any issues with the fuel and ignition systems, as well as the cooling mechanisms, which were vital for keeping the engine from overheating during high-speed flights or extended periods of combat.

Another critical step in the final assembly of the Corsair was the testing of its flight control systems. The aircraft’s ailerons, rudder, and elevators had to be precisely calibrated to allow for smooth handling and maneuverability during combat. The aircraft’s cockpit, which housed the pilot, was also thoroughly examined. The arrangement of instruments and controls had to be optimized for ease of use and quick access, ensuring that the pilot could focus on the mission rather than fumbling with equipment.

Finally, the aircraft’s exterior was given a fresh coat of paint, typically in military colors such as Navy blue or dark gray. The markings, including squadron insignias, tail numbers, and other identifying features, were carefully applied to ensure that the plane met military specifications. These markings were not just cosmetic but also served important operational purposes, helping pilots and ground crews quickly identify individual aircraft in the chaos of combat.

The Role of Skilled Labor in Aircraft Production

The assembly of the Corsair was not just a matter of following blueprints and assembly line procedures; it was also a reflection of the skill and dedication of the workers who built these planes. Many of the workers in the Vought factories were highly trained artisans who took great pride in their work. The assembly process was labor-intensive, with workers spending long hours on their feet, ensuring that each plane was assembled to perfection.

In many cases, these workers had backgrounds in fields such as engineering, machining, or aviation, and their expertise was crucial to the success of the production process. The teamwork and coordination required for the final stages of the Corsair’s assembly were immense. Inspectors, technicians, engineers, and workers all played a vital role in the process, ensuring that each aircraft was built to the highest standards of quality.

As the war raged on, the demand for fighter aircraft like the Corsair increased, and the factories had to ramp up production to meet the needs of the military. Despite the pressures of wartime production, the workers at Vought maintained a commitment to quality that ensured the Corsair would become one of the most iconic and successful fighter aircraft of World War II.

The Legacy of the Corsair

By the time the final touches were applied to each Corsair and it was ready for flight, it was far more than just an aircraft. It was a product of human ingenuity, hard work, and dedication. The final stages of the Corsair’s assembly were a microcosm of the larger effort to win the war and protect freedom. These planes, once they were in the air, would go on to achieve legendary status in the annals of aviation history.

In the Pacific theater, the Corsair proved to be a formidable adversary for the Japanese forces, and its role in battles such as the Battle of Midway and the Battle of the Philippine Sea became part of its storied legacy. Its success on the front lines was a direct result of the careful and meticulous process that occurred on the assembly lines back home.

The Corsair’s combination of speed, power, and versatility made it one of the most beloved aircraft of its time, not only by the military personnel who flew it but also by those who built it. As the last Corsairs rolled off the assembly line and into the skies, they embodied the spirit of innovation, resilience, and determination that defined the era.

Today, the F4U Corsair is remembered as one of the greatest aircraft ever built, and its legacy lives on in museums, airshows, and the hearts of aviation enthusiasts around the world. Its journey from the assembly line to the skies serves as a reminder of the incredible effort and attention to detail that went into producing these warplanes, ensuring that they were ready to meet the challenges of a world at war.

News

Little Emma Called Herself Ugly After Chemo — Taylor Swift’s Warrior Princess Moment Went VIRAL BB

When Travis Kelce’s routine visit to Children’s Mercy Hospital in November 2025 led him to meet 7-year-old leukemia patient Emma,…

The Coronation and the Cut: How Caitlin Clark Seized the Team USA Throne While Angel Reese Watched from the Bench BB

The narrative of women’s basketball has long been defined by its rivalries, but the latest chapter written at USA Basketball’s…

“Coach Made the Decision”: The Brutal Team USA Roster Cuts That Ended a Dynasty and Handed the Keys to Caitlin Clark BB

In the world of professional sports, the transition from one era to the next is rarely smooth. It is often…

Checkmate on the Court: How Caitlin Clark’s “Nike Ad” Comeback Silenced Kelsey Plum and Redefined WNBA Power Dynamics BB

In the high-stakes world of professional sports, rivalries are the fuel that keeps the engine running. But rarely do we…

The “Takeover” in Durham: How Caitlin Clark’s Return Forced Team USA to Rewrite the Playbook BB

The questions surrounding Caitlin Clark entering the Team USA training camp in Durham, North Carolina, were valid. Legitimate, even. After…

From “Carried Off” to “Unrivaled”: Kelsey Mitchell’s Shocking Update Stuns WNBA Fans Amid Lockout Fears BB

The image was stark, unsettling, and unforgettable. As the final buzzer sounded on the Indiana Fever’s 2025 season, Kelsey Mitchell—the…

End of content

No more pages to load