September 9th, 1940. In Englewood, California, 11:47 a.m. Inside North American Aviation’s manufacturing facility, Chief Engineer Edgar Schmood stood beside a gleaming silver aircraft that shouldn’t exist. Just 102 days earlier, this plane was nothing but rough sketches on a drafting table.

Now it sat complete, ready to challenge everything the aviation world understood about cooling systems. Beneath the fuselage, a peculiar bulge caught the morning light. Not a bomb, not a fuel tank. A radiator scoop that would rewrite the physics of flight. Here’s what nobody expected. This cooling system wouldn’t just dissipate waste heat.

Under the right conditions, it would convert that thermal energy into forward thrust, transforming a fundamental aerodynamic liability into an asset. The Germans called it impossible. British engineers remained skeptical. Even American designers couldn’t fully explain how it worked. But the mathematics didn’t lie, and neither would the combat records.

This is the story of how British scientist Frederick William Meredith’s radical 1935 theory became the P-51 Mustang’s secret weapon. A physics phenomenon so counterintuitive that 80 years later, engineers still debate whether it actually produced thrust or simply eliminated drag. What we’re about to uncover isn’t just about one airplane.

It’s about solving an engineering problem that had plagued every liquid cooled aircraft since World War I. To understand why the P-51’s radiator was revolutionary, we need to travel back to the mid 1930s when aircraft speeds were finally breaking 300 mph. Designers faced a brutal dilemma. Liquid cooled engines offered smooth aerodynamic cowlings and better high alitude performance than air cooled radials, but they demanded radiators.

Chunks of metal and fins sitting directly in the airirstream, creating massive drag. At the Royal Aircraft Establishment in Farmborough, England, a 35-year-old engineer named Frederick William Meredith was obsessed with this problem. While his colleagues focused on minimizing radiator drag through clever positioning, Meredith asked a different question.

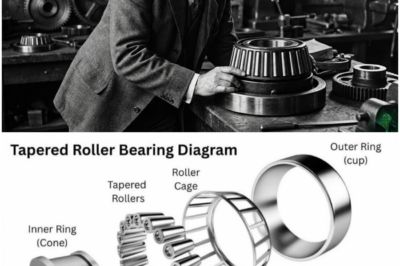

What if we could use the waste heat itself? On August 14, 1935, Meredith published his groundbreaking paper, cooling of aircraft engines, with special reference to ethylene glycol radiators and closed induct. The title was dry. The implications were explosive. Meredith’s insight was elegant. Every piston engine wastess enormous thermal energy.

Heat that must be dumped into the atmosphere. Traditionally, this represented pure loss, energy spent without benefit plus the aerodynamic penalty of the cooling apparatus. But Meredith realized something extraordinary. If you carefully shape the air passage around a radiator, that waste heat could add velocity to the exhaust airream. The heated air expands.

If channeled through a converging nozzle, that expansion accelerates the flow. Accelerated flow means momentum. Momentum means thrust. It wasn’t perpetual motion or free energy. It was thermodynamics, specifically an open braen cycle, compression at the inlet, heat addition at the radiator, expansion through the exit nozzle.

Three simple processes that executed correctly could offset or even eliminate cooling drag entirely. The theory was sound. The mathematics checked out. There was just one problem. Nobody had actually built one that worked as predicted. British designers immediately tried implementing Meredith’s concepts. The results were mixed.

The Supermarine Spitfire incorporated a ducted radiator under the wing for its first flight on March 5th, 1936, just 7 months after Meredith’s paper. The Hawker Hurricane followed. Both used the new Rolls-Royce Merlin engine cooled by ethylene glycol, exactly the configuration Meredith had theorized about, but neither design achieved the dramatic drag reduction Meredith’s equations promised.

The German Messers Schmidt BF 109 initially used an underslung radiator, then switched to wing-mounted radiators in 1938. These were even less efficient, suffering from severe inlet separation, turbulent air flow that destroyed cooling effectiveness, and increased drag. What went wrong? Three critical failures plagued early implementations.

First, duct geometry. Most designs used extremely short passages between the inlet and radiator face. The Spitfire and BF- 109 had duct lengths measured in inches, not feet. When air had to turn at sharp angles, sometimes 30 or 40°, it separated from the duct walls, creating turbulence.

Turbulent flow meant reduced pressure recovery, inefficient heat transfer, and increased drag. Second, boundary layer contamination. Aircraft fly through air that sticks to their surfaces, the boundary layer. This slowm moving turbulent air is terrible for radiator cooling. Early designs allowed boundary layer air to flow directly into radiator inlets, reducing efficiency by 15 to 20%.

Third, exit geometry. Meredith’s theory required carefully shaped converging nozzles to accelerate the heated air. Most designs used simple flaps or doors with minimal attention to aerodynamic shaping. Without proper nozzle design, the expanding hot air simply created turbulent wakes instead of useful thrust.

The BF- 109G suffered so badly from these issues that its cooling drag reached 14% of total drag, an enormous penalty. Opening the radiator flaps at high power settings could reduce top speed by 30 mph. Even successful aircraft like the Spitfire never achieved true Meredith effect thrust. They reduced cooling drag compared to earlier designs, primarily through variable exit doors that restricted air flow during cruise.

But the physics Meredith had promised remained elusive. By 1940, many engineers wondered if the Meredith effect was theoretical fantasy rather than practical reality. Then, North American Aviation received an unusual request from the British Purchasing Commission. April 1940, Los Angeles, California. The British Purchasing Commission approached North American Aviation with an urgent demand.

Design and build a completely new fighter aircraft to supplement Curtis P40 production. Required delivery January 1941. That gave NAA’s team exactly 120 days to design, build, and fly a prototype. Most companies would have declined. NAA President James Dutch Kindleberger saw opportunity. Leading the design team was Edgar Schmood, a 41-year-old Austrian-born engineer with an obsessive attention to aerodynamic efficiency.

Schmood had worked at Foker and general aviation before joining NAA. He understood European design philosophy and American manufacturing capability equally well. The British requirement was specific. A fighter powered by the Allison V1710 engine capable of high-speed, lowaltitude operations. Range and speed mattered more than climbing ability.

Schmood made two revolutionary decisions that would define the NA73X prototype, later christened the Mustang. Decision one, the NA 66 series laminer flow wing. This new air foil design maintained smooth low drag air flow over a longer cord length than conventional wings. Lower wing drag meant the aircraft could tolerate slightly higher cooling drag while maintaining competitive speed.

Decision two, a vententral radiator scoop positioned aft of the wing’s trailing edge. This second choice was where Meredith’s theory would face its ultimate test. Schmood studied the cooling system problems plaguing European fighters. He obtained wind tunnel data from the Curtis XP46 program.

NAA paid Curtis $56,000 for this technical information. The XP46 had explored aftmounted radiator scoops, though Curtis never fully developed the concept. Shmeir went further, much further. The P-51’s radiator installation incorporated several breakthrough features that earlier designs had missed. The long diffuser from the inlet to the radiator face.

The duct ran nearly 30 in, three times longer than the Spitfire’s installation. This length allowed for gradual controlled deceleration of incoming air without separation. The diffuser angle never exceeded 7° staying well within the boundaries of attached flow. Boundary layer separation. The inlet incorporated a carefully designed scupper, a small opening that bled off the slowmoving boundary layer air before it could enter the main duct.

Only high energy, clean air flow reached the radiator matrix. This single feature improved cooling efficiency by approximately 15%. Convergent exit nozzle. The aft portion of the scoop narrowed smoothly, creating a true convergent nozzle. Variable exit doors allowed precise control of the nozzle throat area.

Close the doors and crews for maximum velocity acceleration. open them for climb and ground operations when maximum cooling mattered more than drag reduction. Integrated heat exchangers. The scoop housed three separate units, the primary engine coolant radiator, the oil cooler, and the intercooler for the supercharger. All three benefited from the same carefully managed air flow.

The prototype NA73X was completed on September 9th, 1940, exactly 102 days after contract signing. First flight came on October 26th with test pilot Vance Breeze at the controls. Initial testing revealed problems. The radiator scoop produced an audible rumble at certain speeds. Clear evidence of inlet separation.

NAA engineers performed full-scale wind tunnel testing using an actual P-51 airframe with the outer wing panels removed. They discovered separation occurring where the duct diverged too steeply. The solution? Refine the inlet shape and optimize the boundary layer scupper design. By the time the P-51B entered service in 1943, now powered by the Packard V1650 Merlin instead of the original Allison, the radiator system had been perfected through hundreds of test flights.

But did it actually produce thrust or simply reduce drag to near zero? Understanding what the P-51’s radiator actually accomplished requires examining three key measurements. Pressure recovery, temperature delta, and exit velocity. Pressure recovery. When ram air enters the scoop at high speed, it slows down and compresses, converting kinetic energy into pressure.

Efficient diffusers can recover 80 to 85% of the dynamic pressure. The P-51’s design achieved 84% recovery with the exit door closed. exceptional performance that minimized losses before the air even reached the radiator. Temperature delta. The greater the difference between coolant temperature and inlet air temperature, the more heat energy transfers to the cooling air.

The Merlin enginees ethylene glycol coolant operated at 212° F, 100° C. On a standard day at altitude, inlet air might be 35 degrees Fahrenheit. That 177 degree temperature delta meant substantial heat addition. Modern testing by experimental aircraft builders replicating the P-51’s radiator design have measured temperature deltas exceeding 120° F under typical cruise conditions.

At that temperature gain, the heated air expands significantly. Exit velocity is the critical measurement. If exit air velocity exceeds the aircraft’s true air speed, the radiator system produces net thrust. If it merely matches air speed, cooling drag drops to zero. Anything less and you still have cooling drag, just reduced compared to conventional installations.

Flight test data from P-51B and P-51D variants suggests the system achieved velocity par exit velocity matching forward speed during cruise conditions between 15,000 and 25,000 ft at speeds of 350 to 400 mph. North American Aviation’s internal documentation indicates cooling drag at top speed was effectively neutralized.

At 437 mph, the P-51D’s maximum speed. The radiator system neither added significant thrust nor imposed measurable drag penalty. This was extraordinary. Comparable aircraft like the Spitfire and BF 109 suffered cooling drag ranging from 8 to 14% of total drag at maximum speed. The P-51 had reduced it to essentially zero.

But modern testing has revealed something even more interesting. Experimental builders constructing P-51 replica scoops with modern aluminum radiators, thinner and more efficient than 1940s designs, have measured exit velocities 4 to 5% higher than forward speed under certain conditions. With coolant temperatures of 180 degrees Fahrenheit and temperature deltas of 125 degrees Fahrenheit at speeds around 150 mph, the heated air genuinely accelerates beyond aircraft speed.

This suggests the original P-51 with its deeper, more restrictive 1940s radiator design probably achieves something close to zero net drag rather than positive thrust. The internal pressure losses from the radiator matrix likely consumed the potential thrust gains. However, racing P-51s modified for air racing competition tell a different story.

Aircraft like Voodoo and Strega incorporate dramatically revised cooling systems. Longer, shallower scoops with modern thin core radiators optimized inlet geometry without boundary layer scuppers no longer needed at racing speeds. and carefully shaped exit nozzles. These aircraft almost certainly achieve net forward thrust from their cooling systems during high-speed racing passes.

The impact on combat performance was undeniable. The P-51B entered combat over Europe in December 1943 with the 354th Fighter Group. Its combination of speed, range, and high altitude capability immediately changed the strategic bomber campaign. Maximum speed was 437 mph at 25,000 ft with the Packard V1650 7 Merlin engine producing 1695 horsepower.

Combat radius was 750 mi with drop tanks, enough to escort bombers to Berlin and back. The P-51D with its bubble canopy and six.5 caliber machine guns became the definitive long range escort fighter of World War II. Over 15,000 Mustangs were built between 1940 and 1945. The radiator design contributed 15 to 20 mph to the P-51’s top speed compared to what it would have achieved with a conventional cooling installation.

In air combat, 15 mph can mean the difference between catching an enemy fighter or watching it escape. The P-51’s cooling system validation had consequences beyond one aircraft design. Ramjet research. Meredith’s theory directly inspired early American ramjet development. A ramjet operates on nearly identical principles.

ram air compression, heat addition, and expansion through a nozzle. Researchers recognized the similarity immediately. By the late 1940s, engineers explicitly studied Meredith ramjets as potential auxiliary propulsion systems. Though practical ramjet engines evolved in different directions, the fundamental physics Meredith identified remained valid.

post-war applications. Several post-war aircraft attempted to refine the concept. The British Napier Hen T5 racing aircraft designed in 1938 1940 featured an even more advanced implementation than the P-51 with the exit duct running the entire length of the aft fuselage to optimize expansion. Though the T5 crashed during testing before proving the system, its design represented the theoretical ideal.

Racing heritage. Modern unlimited class air racing aircraft. Almost exclusively modified P-51s have evolved the cooling system far beyond 1940s capabilities. Current record holders cruise at speeds approaching 500 mph and their radiator systems contribute measurable forward thrust. Formula 1 connection.

The Meredith effect has found new life in modern Formula 1 racing cars. Since the 1980s, F1 designers have mounted radiators inside carefully shaped side pods that function as Meredith ducts. The heated exhaust air accelerates through convergent rear outlets, reducing the aerodynamic penalty of cooling systems. Misconceptions persist.

Even today, confusion surrounds what the P-51 system actually achieved. Aviation forums and websites frequently claim the radiator produced 250 to 400 lb of thrust. figures unsupported by period documentation or physics calculations. These myths persist because the reality near zero cooling drag rather than substantial thrust sounds less exciting.

The truth is impressive enough. North American aviation achieved what most engineers considered impossible, making the cooling system aerodynamically invisible. Why this matters today? The engineering principles that made the P-51’s radiator work remain relevant in modern aerospace design. Electric vehicle cooling.

Battery packs in electric vehicles generate substantial heat that must be dissipated. Tesla and other manufacturers now incorporate Meredith inspired cooling ducts that use vehicle motion to enhance cooling efficiency while minimizing aerodynamic drag. The physics haven’t changed, only the application. Hypersonic flight vehicles traveling above Mach 5 face extreme thermal management challenges.

Researchers developing hypersonic aircraft study Meredith cooling as one approach to using waste heat productively rather than treating it as pure liability. Unmanned aircraft. Long endurance drones powered by internal combustion engines face similar cooling versus drag trade-offs that the P-51 engineers solved.

Modern UAV designers explicitly reference Meredith effect principles when optimizing cooling installations. The broader lesson transcends specific applications. Waste streams can become resources through clever engineering. Edgar Schmood and his North American aviation team didn’t just copy Frederick Meredith’s 1935 paper.

They executed the theory with precision that had eluded earlier attempts. Long diffusers, boundary layer separation, convergent nozzles, variable exit geometry. Each detail mattered. The P-51 Mustang achieved its legendary status through multiple innovations working in concert. The laminer flow wing, the Merlin engine, structural efficiency, and yes, that peculiar belly scoop that turned physics theory into battlefield advantage.

Cooling drag didn’t disappear because of magic or aerodynamic trickery. It disappeared because engineers finally understood how to shape air flow, manage pressure gradients, and harness thermodynamic principles that had existed since before aircraft were invented. Frederick Meredith proved the mathematics in 1935. Edgar Schmood built the hardware in 1940.

Combat Over Europe in 1944 validated both. The P-51’s radiator stands as proof that fundamental physics problems often have elegant solutions. If you’re willing to challenge conventional wisdom and execute with precision, if this hidden engineering secret fascinated you, we’ve got four more P-51 innovations to uncover in this series.

Each one challenged what engineers thought possible. Subscribe now and hit the notification bell so you don’t miss how North American aviation achieved the impossible. 102 days from contract to first flight. That story involves midnight shifts, British spies, and a cooling system that shouldn’t have worked. Drop a comment. Did the P-51’s radiator produce thrust or just eliminate drag? The engineers still debate this 80 years later.

Let’s continue the discussion. Thanks for diving deep into military engineering history with us. Remember, the best solutions often hide in plain sight, waiting for someone brave enough to execute the theory. See you in the next

News

How a US Soldier’s ‘Payload Trick’ Killed 25 Japanese in Okinawa and Saved His Unit DT

At 0330 hours on April 13th, 1945, Technical Sergeant Bowford Theodore Anderson stood inside a tomb carved from Okinawan limestone….

Jimmy Fallon SPEECHLESS When Keanu Reeves Suddenly Walks Off Stage After Reading This Letter DT

Keanu Reeves finished reading the letter, lifted his head, and without saying a single word, walked off the stage. 200…

They Said One Man Could’nt Do It — Until His Winchester Model 12 Killed 62 Japanese in 3 Hours DT

At 11:47 a.m. February 19th, 1945, Vincent Castayano crouched in volcanic ash on Ewima, gripping a Winchester Model 12 shotgun…

Kevin Costner & Jewel CAN’T Hold Back Tears When 7-Year-Old’s SHOCKING Words Stop Jimmy Fallon DT

Three words from a seven-year-old boy changed late night television history forever. But it wasn’t just what little Marcus said…

Jimmy Fallon STOPS His Show When Keanu Reeves FREEZES Over Abandoned Teen’s Question DT

Keanu Reeves froze mid- interview, walked into the Tonight Show audience, and revealed the childhood pain he’d carried for decades….

What Javier Milei said to Juan Manuel Santos… NO ONE dared to say it DT

August 17th, 1943, 30,000 ft above Schweinfort, Germany, the lead bombardier of the 230 B17 flying fortresses approaching Schweinford watched…

End of content

No more pages to load