October 15th, 1944. A Japanese submarine commander raises his periscope through the crystal waters of Uli at what he sees will haunt Imperial Japan’s naval general staff for months. Through that narrow lens, Lieutenant Commander Yukio counts not warships, but something that defies every law of naval warfare he has ever learned.

Massive floating structures, steam rising from welding operations, cranes moving equipment that weighs more than fighter planes. The aircraft carrier USS Franklin sits cradled in one of these metal monsters. Her flight deck swarming with over a thousand workers. But here is the part that makes S’s blood run cold. This carrier was supposed to be out of the war.

Japanese intelligence had confirmed catastrophic damage just 3 weeks ago. Yet there she sits being rebuilt. Not in San Francisco, not in Pearl Harbor, but right here, 3,000 mi from the nearest American shipyard. That night, Sato sends a coded message that will shock Tokyo. Enemy possesses floating factories capable of major carrier reconstruction.

What Sato had witnessed would become one of World War II’s most decisive and least understood secrets. The Americans had figured out how to bring Detroit and Pittsburgh to the front lines. They had built floating machine shops. And by the time Japan understood what they were facing, it was already too late.

If you had told Admiral Osami Nagono in early 1941 that Japan would lose the Pacific War because of repair ships, he would have laughed in your face. The mathematics seemed perfect. His intelligence officers had studied every American shipyard on the Pacific coast. Mayor Island in California could handle two carriers for major repairs.

Puet Sound in Washington could manage three. Pearl Harbor, the closest facility to any potential combat zone, could service four carriers at most if pushed to absolute limits. Commander Minoru Genda, the brilliant architect of the Pearl Harbor attack, had calculated something beautiful in its simplicity. If Japanese forces could damage six to eight American carriers in the first year of war, repair bottlenecks would American naval aviation for 12 to 18 months.

The Pacific Ocean itself would become Japan’s ally. A damaged carrier would need to steam 3,000 mi back to the West Coast. That voyage alone took two weeks, then repairs, then crew training, then the voyage back. Four to 6 months minimum for any serious damage. Admiral Isuroku Yamamoto himself had endorsed these calculations.

His chief of staff presented detailed charts showing American industrial limitations. Yes, America could build carriers faster than Japan. Everyone knew that. But carrier operations required more than hulls and engines. They demanded specialized machine shops. Precision tooling measured in thousandth of an inch.

Skilled technicians who had trained for years. These things existed only in established naval yards. You could not simply pack them onto a ship and sail them across the ocean. That would be insane. That would be impossible. The Japanese were about to learn a very painful lesson about American industrial creativity.

Robert Patterson never expected to make history. In 1938, he was just another machinist at the Ford River Rouge plant in Detroit, the largest industrial complex in the world. Patterson had learned his trade the hard way, spending 16 years mastering the art of precision metal work. He could machine parts with tolerances so fine that human hair seemed thick by comparison.

He could cast gears, wind motors, and fabricate components that engineers said could not be built outside specialized factories. When the Navy came recruiting in 1940, Patterson almost did not apply. He was 42 years old with a wife and three kids. But something in the recruitment poster caught his eye. The Navy wanted men who could build things, not just sailors, builders.

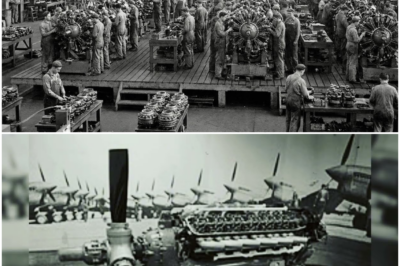

Patterson reported to the Brooklyn Navyyard in January 1941 and received an assignment that confused him. USS Vulcan, a repair ship. Patterson had expected a battleship, maybe a carrier, something that would fight. Instead, they sent him to what looked like a floating factory, 625 ft of machine shops, foundaries, and electrical laboratories.

Patterson’s commanding officer, Commander James Morrison, gathered his new recruits on the first day with words that seemed almost prophetic. Gentlemen, you are not here to fight the enemy. You are here to ensure that those who fight never have to stop. We are going to be Detroit made mobile. We are going to rebuild anything the Navy can float.

Patterson looked around at his fellow crewmen, machinists from Pittsburgh steel mills, electricians from General Electric plants, metallurgists from automotive factories. The Navy had gathered 1,400 of America’s finest industrial craftsmen onto a single ship. They had no idea they were about to revolutionize naval warfare.

The concept that became USS Vulcan originated from a simple but revolutionary question posed by CaptainSamuel Robinson of the Bureau of Ships in early 1941. What if we stopped sending damaged ships to the repair yards and started sending the repair yards to damaged ships? His colleagues thought he was crazy, a floating machine shop capable of major warship reconstruction.

The specifications alone seemed impossible. You would need lathes capable of turning propeller shafts 40 ft long. Foundaries that could cast components weighing several tons. Electrical shops equipped to rewind motors massive enough to power a carrier’s elevators. Machine tools with precision measured in millions of inches.

All of this needed to operate while floating on the ocean, pitching and rolling with the waves exposed to salt air that corroded everything it touched. The Navy’s engineering bureau rejected the initial proposal. Too ambitious, they wrote across the file. Technically unfeasible, prohibitively expensive. Robinson refused to give up. He assembled a team of civilian engineers and presented revised specifications.

The floating machine shop would carry more manufacturing capability than some entire nations possessed. Her crew would include not ordinary sailors, but industrial craftsmen recruited directly from American factories. She would carry technical drawings for every major class of American warship, allowing her to manufacture replacement parts without reference to shore-based engineering departments.

She would be in effect American industrial civilization made portable. The bureau approved the design in March 1941. USS Vulcan was commissioned 3 months before Pearl Harbor. Her first commanding officer captured the vessel’s unprecedented mission in his commissioning speech. We carry within this hull the productive capacity of a major American city.

We will prove that geography is no obstacle to American industrial power. Nobody was laughing anymore. The first test came sooner than anyone expected. October 1942. The waters around Guadal Canal had become a graveyard for American warships. Japanese battleships Congo and Haruna had bombarded Henderson Field on October 13th, destroying what appeared to be America’s entire air capability in the Solomon Islands.

Japanese reconnaissance confirmed the devastation. Aircraft reduced to burning wreckage. Fuel dumps destroyed. Runways cratered beyond use. Imperial General Headquarters in Tokyo authorized celebration announcements. American air power at Guadal Canal had been eliminated. Then something impossible happened.

3 days later, Japanese pilots reported massive American air activity from that same field. Intelligence officers dismissed the reports as pilot error. How could the Americans rebuild their air capabilities so quickly? They did not have supply ships large enough. They did not have repair facilities close enough.

The answer floated offshore where USS Vulcan had anchored just 12 hours after the bombardment. Robert Patterson and his fellow machinists worked 72 consecutive hours manufacturing replacement parts for damaged aircraft. Vulcan’s foundaries cast new engine blocks while shells still fell in the distance. Her electrical shops rewound burned out motors.

Her precision machinists fabricated control surfaces and landing gear components from raw aluminum stock. Patterson later described those three days as the most exhausting and exhilarating of his life. We made parts that normally took weeks to manufacture in shore facilities. We improvised, we adapted.

We worked until our hands bled and then we worked some more. By the time we finished, aircraft that should have been scrap metal were flying combat missions. The Japanese never figured out what had happened. Their intelligence assessed American repair capabilities based on shore facilities and traditional supply chains. They had not imagined that Americans would bring the factory to the battlefield.

The true demonstration of floating machine shop capability came on October 26th, 1942 when Japanese aircraft damaged the carrier USS Enterprise during the Battle of Santa Cruz Islands. Multiple bomb hits had torn through her flight deck and devastated her elevator systems. Captain Tadashi Nakajima observing from the Japanese carrier Shokaku calculated that Enterprise would require 6 months minimum for repairs.

Standard doctrine indicated that elevator damage demanded dry dock facilities and specialized lifting equipment available only at Pearl Harbor or the West Coast. Japanese intelligence wrote Enterprise off as eliminated from the Pacific War for at least half a year. 28 days later, Enterprise reappeared in combat during the naval battle of Guadal Canal.

Her elevators functioned perfectly. Her flight deck showed no evidence of previous damage. She launched aircraft that destroyed a Japanese battleship. Nakajima would spend years trying to understand what had happened. The transformation had occurred at Numia, where USS Vulcan performed what amounted to complete reconstruction of Enterprises damagedsections.

Patterson personally supervised the elevator repairs. We essentially built a new elevator system from raw steel, cast the gears, machined the reduction units, wound the motors. Everything except the basic structure was manufactured aboard Vulcan using tools and equipment we carried with us. Enterprise emerged from those 28 days, not merely repaired, but improved.

Her radar had been upgraded. Her anti-aircraft systems enhanced. Damage had become opportunity. Japanese naval intelligence began receiving reports that challenged their fundamental understanding of American capabilities. A cruiser observed at Aspiritu Sananto with catastrophic bow damage returned to combat in 3 weeks.

A destroyer with her entire forward section blown off reappeared in 14 days with what looked like a completely new bow. Carriers suffering damage that should have removed them from the war for months were returning in weeks. Vice Admiral Chui Nagumo, the hero of Pearl Harbor, reviewed these reports with growing concern.

His staff could not explain the observations. Traditional intelligence analysis assumed repair timelines based on shore facility capabilities. Something was wrong with their calculations. The breakthrough in understanding came from submarine commander Yahachi Tonab who observed the cruiser USS New Orleans being rebuilt near a Spirit Sananto.

New Orleans had lost her entire bow section to a Japanese torpedo. Tanabi watched through his periscope as what appeared to be a floating factory manufactured an entirely new bow for the cruiser complete with compartments, weapons mounts, and crew facilities. His report reached Admiral Yamamoto’s headquarters within days.

The enemy vessel appeared to be constructing rather than repairing the damaged cruiser. Multiple cranes operated simultaneously. Welding proceeded on three levels. This was not repair. This was reconstruction. But here is what the Japanese did not yet understand. Vulcan was just the beginning.

By early 1943, America was building an entire fleet of these floating factories. USS Vestal, USS Ajax, USS Hector. Each one represented more manufacturing capability than existed in some nations entire industrial bases. And the Americans were just getting started. The question was no longer whether floating machine shops would change the war.

The question was whether Japan could survive what was coming. In part two, we will see how these floating factories enabled American forces to achieve something that seemed impossible, an operational tempo that Japanese defenders simply could not match. We will witness Japanese submarines receive desperate orders to sink repair ships rather than combat vessels because destroying one floating machine shop would hurt America more than sinking 10 warships.

We will learn how Master Chief Patterson and his fellow craftsmen rebuilt carriers that Japanese pilots had already celebrated destroying. And we will see the moment when Japan’s admirals finally understood that they were not fighting the American Navy. They were fighting American industry itself made mobile and brought directly to their doorstep.

The war had changed, but the Japanese did not yet know how badly. In part one, we watched Master Chief Robert Patterson and his crew aboard USS Vulcan achieved something the Japanese thought impossible. They rebuilt the carrier enterprise in 28 days. They restored Henderson Fields air power in 72 hours. They proved that American industrial might could be made portable.

But proving a concept and convincing the military establishment are two very different things. Here is a statistic that should disturb you. In early 1943, despite Vulcan’s success, 73% of damaged American warships were still being sent back to the West Coast for repairs. The floating machine shop program remained an experiment, a curiosity, something that worked in theory, but had not earned the trust of admirals who had fought wars the traditional way for decades.

And while American bureaucrats debated Japanese submarines were sinking an average of four Allied ships per week in the Pacific, the clock was ticking. Lives were being lost. and the very solution that could save them sat anchored at Numea waiting for permission to prove itself again. This is the story of how Robert Patterson fought a war within a war and how one stubborn admiral almost cost America everything.

Vice Admiral Robert Gormley had commanded the South Pacific area since June 1942. He was Old Navy through and through. Anapapolis class of 1906. 40 years of service built on tradition hierarchy and doing things by the book. When reports of Vulcan’s success reached his headquarters, Gormley’s response was not celebration. It was suspicion.

The admiral summoned Commander James Morrison Vulcan’s commanding officer to his flagship on November 3rd, 1942. Patterson accompanied Morrison as the ship’s senior enlisted technical expert. What followed was one of the most consequential confrontations of thePacific War. Gormley sat behind his desk.

The reports spread before him like evidence of a crime. Commander, these repair timelines you are claiming are simply not credible. Enterprise rebuilt in 4 weeks. That is not repair. That is either exaggeration or recklessness. Morrison kept his voice steady. Admiral, I can provide documentation for every component manufactured and installed.

Chief Patterson here supervised the elevator reconstruction personally. Gormley turned his cold gaze to Patterson. A enlisted man performing work that should require a naval shipyard. And you expect me to stake my fleet’s readiness on this? Patterson felt his jaw tighten but held his composure. Sir, with respect.

Enterprise is currently conducting combat operations. Her elevators function better than before the damage. The work speaks for itself. The admiral’s response cut like a blade. The work speaks of shortcuts and improvisation. When one of your juryrigged repairs fails in combat and sailors die, who answers for that? You, your commander, or me? The meeting ended with Gormley’s verdict? Vulcan would continue limited repair operations, but all major work would still require transport to Pearl Harbor or the mainland.

The floating machine shop program would not expand. Patterson walked out of that meeting understanding something terrible. They had won the battle against Japanese bombs. Now they had to win the battle against American bureaucracy and they were losing. But Patterson found an unexpected ally in the most unlikely place.

Captain Edward Cochran served as the Bureau of Ships representative in the South Pacific. Unlike Gormley, Cochran had spent his career in engineering rather than command. He understood machines. More importantly, he understood what machines could become. Cochran had reviewed Vulcan’s technical reports with growing excitement.

The metallurgical analyses, the precision measurements, the innovation under pressure. This was not juryrigging. This was American engineering genius operating at the bleeding edge of possibility. He sought out Patterson 3 days after the disastrous meeting with Gormley. Chief, I have read every report your team has filed.

The work you did on Enterprise was not just adequate, it was superior to original construction specifications. Patterson allowed himself a bitter laugh. Tell that to the admiral. Cochran leaned forward with intensity in his eyes. I intend to, but I need more than reports. I need a demonstration that no one can dismiss.

Something so spectacular that even Gormley cannot ignore it. What if I could get you an official trial full documentation, Naval Observers? A ship with damage so severe that traditional methods would write her off and 30 days to prove the impossible. Patterson considered the offer. The risk was enormous.

Fail publicly, and the floating machine shop program would be buried forever. But succeed, and they could change the war. What ship? Patterson asked. Cochran smiled grimly. USS Minneapolis. She took a torpedo at Tacaparanga, lost 40 ft of her bow. Current estimate for repairs is 8 months at Mayor Island. I am proposing you do it in 30 days at Tulagi. That is not a repair job.

That is building a new ship. Exactly. Cochran replied. That is exactly what we need to prove. The official trial began on December 15th, 1942. Minneapolis lay anchored at Tulagi, her bow, a twisted nightmare of torn steel. The torpedo had detonated directly beneath her forward turret, obliterating everything forward of frame 67.

Compartments that once held sailors were now open wounds exposed to the Pacific. Admiral Gormley had sent three observers. Their orders were explicit. Document everything. Report any deviation from proper procedure. find reasons to shut this down. Patterson gathered his team on Vulcan’s machine deck at 0400.

Around him stood 200 of the finest industrial craftsmen America had ever produced. Machinists from Detroit, welders from Pittsburgh, electricians from Skenctity, men who had built the machines that built the nation. Gentlemen, Patterson addressed them. We have 30 days to build a new bow for a heavy cruiser.

That is 40 ft of hull structure, 16 watertight compartments, six weapons mounts, 80,000 lb of steel that has to be manufactured, shaped, and installed while we sit in an anchorage that Japanese submarines visit regularly. The Navy says it cannot be done outside a shipyard. We are going to prove them wrong. Day one focused on assessment.

Patterson personally crawled through Minneapolis’s damaged sections, mapping exactly what needed replacement. The destruction was worse than reports indicated. Frame 63 had buckled. The keel showed stress fractures extending 20 ft beyond the visible damage. Traditional repair doctrine would condemn the ship. Patterson saw opportunity.

Day three brought the first crisis. Vulcan’s foundry attempted to cast the main keel extension, a component weighing 12,000 lb. The first pour failed. Metal crystallizedincorrectly. Gormley’s observers noted the failure with barely concealed satisfaction. Patterson ordered the failed casting broken down and remelted. His metallurgists analyzed the failure and adjusted the alloy composition.

The second pour on day five succeeded. The casting exceeded original specifications by 15% in tensile strength. Day 8 through 14 saw the bow structure take shape. Vulcan’s cranes worked around the clock, positioning pre-fabricated sections manufactured in the ship’s workshops. Welders worked in shifts, never stopping the blue light of their torches visible for miles.

Japanese reconnaissance aircraft spotted the activity. On day 11, Patterson received warning of a possible air attack and made a decision that shocked everyone. He refused to halt work. We stop and they bomb us anyway. We keep working and maybe finish before they get here. The attack never came, but the message spread through both fleets.

The Americans were doing something at Tulagi that they considered worth dying for. Day 17 brought the observers interim report. To their visible frustration, they could find no procedural violations. Every weld met Navy specifications. Every component passed inspection. Patterson’s team was not cutting corners.

They were simply working with an efficiency that peaceime bureaucracy had never imagined possible. The bow structure was 60% complete. Traditional shipyard estimates said this phase alone should take 4 months. On day 22, Patterson faced his greatest challenge. The forward fire control systems required calibration equipment that Vulcan did not carry.

Standard procedure demanded the ship return to a major facility. Patterson improvised. His electricians reverse engineered the calibration process using oscilloscopes and measurement tools designed for other purposes. They created a testing protocol from first principles documented every step and achieved calibration accuracy within 03% of factory specifications.

The observers stopped taking notes to simply watch in amazement. Day 28. The new bow was structurally complete. Watertight tests showed zero leakage. The weapons mounts had been installed and aligned. Minneapolis looked like a ship that had never been damaged. But Patterson was not satisfied. We have 2 days left.

Let us make her better than she was. His team spent the final 48 hours installing upgraded radar systems that had just arrived from the States. They reinforced the ammunition handling systems based on lessons learned from other torpedo hits. They improved the drainage in the forward compartments to increase survivability against future attacks. Day 30, December 15th, 1942.

Admiral Gormley’s chief observer, Captain William Henderson, conducted the final inspection. He spent 6 hours examining every weld, every system, every component. Patterson watched him work, waiting for the verdict that would determine the program’s future. Henderson emerged from the forward compartments with an expression Patterson could not read.

“Chief,” he said slowly. “In 40 years of naval service, I have never seen anything like this.” “You did not just repair Minneapolis. You improved her. Her bow structure is stronger than original construction. Her systems are more capable. If I had not watched this happen, I would not believe it was possible.

Patterson allowed himself to breathe. Does this mean? Henderson cut him off. This means I am recommending immediate expansion of the floating machine shop program, full authorization for major repairs, priority allocation of resources. He paused and something like wonder entered his voice.

You just built 40 ft of heavy cruiser in 30 days. Our entire understanding of naval logistics just became obsolete. The Minneapolis trial changed everything. Within 6 weeks, Admiral Gormley had been replaced by the more aggressive William Holly. Hollyy read Henderson’s report and immediately grasped its implications. If Patterson’s team could rebuild a cruiser bow in 30 days, what else could they do? The expansion was explosive.

Vulcan received authorization for unlimited major repairs. Two additional floating machine shops, USS Vestal and USS Hector, were rushed to the Pacific. Patterson found himself promoted and assigned to train repair crews across the fleet. But implementation revealed new challenges. Many ship captains did not trust the floating repairs.

They had spent their careers believing that serious damage meant months in a real shipyard. Changing that mindset required more than orders. It required demonstration. Patterson traveled from Anchorage to Anchorage, personally supervising repairs that proved the concept again and again. A destroyer with her entire stern blown off rebuilt in 18 days.

A submarine with hull breaches that should have been fatal restored to combat capability in 3 weeks. Each success created converts. Each convert spread the gospel of what was possible. The Japanese noticed. By March 1943, their intelligence analystswere reporting something disturbing. American ships were returning to combat far faster than calculations predicted.

Vessels observed with severe damage reappeared in weeks, not months. The Americans seem to be regenerating their fleet like some kind of industrial hydra. Vice Admiral Jinichi Kusaka reviewed these reports with growing alarm. Our entire strategic model assumed six month repair cycles for major damage. If the Americans have reduced this to 1 month or less, our attrition calculations are worthless.

We cannot sink ships faster than they can repair them. He was right. The mathematics of the Pacific War had fundamentally shifted. But Japan had not yet understood the full scope of what they faced. Patterson and his floating machine shops were just getting started. The real revolution was about to begin. Here is where our story takes a darker turn.

Success brought attention and attention brought enemies both foreign and domestic. In April 1943, a captured Japanese submarine commander revealed under interrogation that Imperial Navy headquarters had issued new priority orders. Floating repair vessels were to be targeted ahead of combat ships. The reasoning was coldly logical.

Destroying one repair ship eliminated capabilities equivalent to sinking multiple warships. American floating machine shops had become the most strategically valuable targets in the Pacific. Patterson received this intelligence with grim understanding. We have proven our worth so completely that now they want to kill us more than they want to kill battleships.

But there was another threat Patterson did not see coming. Someone was feeding information to the Japanese. Detailed reports of floating machine shop positions and capabilities were reaching Tokyo through channels that naval intelligence could not identify. a spy operated somewhere in the repair fleet chain of command and they were very very good at their job.

In part three, we will see the Japanese launch their most determined effort to destroy America’s floating machine shop capability. We will watch Patterson and his crews fight for survival against submarine wolf packs and kamicazi attacks, specifically targeting repair vessels. We will uncover the identity of the spy who nearly betrayed everything.

And we will witness the moment when floating machine shops faced their ultimate test. A challenge so severe that even Patterson doubted they could survive it. The hunters had become the hunted. And the war within the war was about to turn deadly. Let us remember how we arrived here. A machinist from Detroit named Robert Patterson proved that American industrial power could be made portable.

His floating machine shop, USS Vulcan, rebuilt the carrier Enterprise in 28 days. His team constructed a new bow for the cruiser Minneapolis in 30 days flat. Against bureaucratic resistance and military skepticism, Patterson demonstrated that damaged warships could return to combat in weeks rather than months. The Navy expanded the program.

Three additional floating machine shops deployed to the Pacific. Japan noticed. And now Tokyo had issued orders that changed everything. Floating repair vessels became priority targets above battleships, above carriers, above anything else in the American fleet. Japanese submarines received specific instructions.

Find the floating factories. Sink them at any cost. In April 1943, American intelligence intercepted a transmission that chilled Patterson to his core. Enemy repair ship positions confirmed. Attack force assembling. The hunters had become the hunted. And somewhere in the American command structure.

A spy was feeding information directly to Tokyo. Admiral Manichi Koga had replaced Yamamoto as commander of the combined fleet after Yamamoto’s death in April 1943. Unlike his predecessor, Koga was a methodical planner who believed in targeting enemy vulnerabilities rather than seeking decisive battle. When intelligence reports about American floating machine shops reached his headquarters, Koga recognized their strategic significance immediately.

He summoned his submarine commander, Vice Admiral Teo Takagi, for an urgent conference. Takagi, these repair ships are more dangerous than carriers. A carrier can launch perhaps 60 aircraft, but a repair ship can restore 10 carriers to combat capability, destroy their repair fleet, and we their entire Pacific operation.

Takagi studied the intelligence photographs with growing appreciation for the challenge. These vessels operate in protected anchorages, Admiral. Heavy destroyer screens, constant air patrols. Approaching them will cost submarines. Koga’s response was cold and absolute. Then we will spend submarines. Assign your best commanders.

I want those floating factories on the ocean floor. The Japanese response was unprecedented in its focus and ferocity. Six submarines from the elite first submarine squadron received orders to penetrate American anchorages, specifically targeting repair vessels.These were not ordinary submarines. They carried Japan’s finest commander men who had sunk Allied shipping across the Pacific. Their new mission was singular.

Find and destroy the floating machine shops or die trying. The first attack came on May 3rd, 1943. Submarine I19 penetrated the defensive screen at Aspiritu Santo and launched four torpedoes at USS Vestal. Three missed. One struck a fuel barge mored alongside, creating a massive explosion that killed 23 sailors, but left Vestal undamaged.

The second attack on May 17th nearly succeeded. I26 penetrated Tulagi Anchorage at night and achieved a firing solution on USS Vulcan herself. Patterson was aboard supervising repairs on the destroyer, USS Aaron Ward. The torpedo passed 18 ft beneath Vulcan’s hull. A magnetic detonator failure saved 700 American lives.

Japanese determination intensified. By June 1943, submarine attacks on American anchorages had increased 400% compared to the previous year. Most targeted support vessels rather than combat ships. The mathematics of Japanese strategy had fundamentally shifted. But the external threat was not Patterson’s only problem. Success had created complications that threatened the entire program from within.

The rapid expansion of floating machine shop operations revealed quality control challenges that peaceime manufacturing had never faced. In July 1943, a propeller shaft manufactured aboard USS Hector failed catastrophically during sea trials on the cruiser USS Honolulu. The shaft had been cast using procedures that worked perfectly aboard Vulcan, but proved inadequate on Hector’s slightly different foundry equipment.

Honolulu limped back to port with a flooded engine room and three dead sailors. The investigation landed on Patterson’s desk like an accusation. Rear Admiral Charles Lockwood, commander of Pacific submarine forces, used the incident to attack the entire floating machine shop concept. I warned that this cowboy approach to ship repair would kill sailors.

Now three men are dead because we trusted factory workers playing Navy instead of proper shipyard procedures. Patterson defended his program with data. Sir, we have performed over 200 major repairs with a 97% success rate. Traditional shipyards operate at 94%. One failure does not condemn the entire concept. Lockwood was unmoved. One failure is one too many.

I am recommending suspension of major repair authorization until proper oversight can be established. The debate escalated to Admiral Chester Nimttz himself. For 3 weeks, the floating machine shop program hung in bureaucratic limbo while Japanese submarines continued their attacks and damaged American ships waited for repairs that were not coming.

Patterson watched helplessly as vessels that could have been restored in days were instead sent on month-long voyages to Pearl Harbor. Every unnecessary mile steamed was fuel wasted time, lost, and opportunity surrendered. He later described those weeks as the darkest of his war. The vindication came through blood and fire at an anchorage called Pervis Bay on August 7th, 1943.

Three Japanese submarines had penetrated the defensive screen simultaneously in the most coordinated attack of the campaign. I17, I25, and I31 approached from different vectors, each carrying orders to target repair vessels. Patterson was aboard Vulcan when General Quarters sounded at 0347. The night exploded into chaos.

I17 launched first four torpedoes streaming toward the destroyer tender USS Whitney. Two struck home. Whitney’s stern erupted in flame. Her repair workshops destroyed. 41 sailors killed instantly. Patterson watched from Vulcan’s deck as I25 surfaced brazenly 800 yd away. Her deck gun already firing at the ammunition ship USS Pyro.

If Pyro detonated, every vessel in the anchorage would die. Patterson made a decision that would define his legacy. He ordered Vulcan’s crew to battle stations and personally took command of the forward 5-in gun mount. Repair ships carried defensive armament, but they were never expected to fight.

Patterson did not care about expectations. Vulcan’s first salvo missed. The second straddled I25’s conning tower. The third struck the submarine’s pressure hall directly below the water line. I25 began settling immediately. her crew abandoning ship into oil sllicked waters, but I31 had achieved firing position on Vulcan herself.

Patterson saw the torpedo wakes approaching four white lines of death cutting through the dark water. He had perhaps 8 seconds to live. The destroyer USS Radford appeared from nowhere. Her captain having ignored orders to protect the anchorage entrance. Radford interposed her hull between the torpedoes and Vulcan. Two torpedoes struck Radford amid ships.

She broke in half and sank in 90 seconds. 112 sailors died so that Vulcan might survive. Patterson watched Radford go down. Men he had shared meals with disappeared beneath burning oil. The price of his program had just been paid in blood. Butthe battle was not finished. I17, having crippled Whitney, was circling for another attack run.

Patterson’s gun crews had found their rhythm now. Vulcan’s 5-in guns fired with desperate precision, joined by weapons from every ship in the anchorage. I17 took seven hits in 40 seconds. Her conning tower shattered. Her hull ruptured. She dove and never resurfaced. Dawn revealed the cost. Whitney burning but salvageable. Radford gone with most of her crew.

173 Americans dead, but also two Japanese submarines destroyed and a third damaged beyond repair. More importantly, Vulcan and the other floating machine shops had survived. Patterson buried his dead and returned to work. Within 72 hours, his crews had stabilized Whitney’s damage and begun repairs on three destroyers damaged in the attack.

The Japanese had thrown their best submarines at the floating machine shops and failed. When Admiral Nimttz received the afteraction report, he made his decision. The floating machine shop program received unlimited authorization. Patterson was promoted to warrant officer. The suspension debate ended permanently.

The impact rippled across the Pacific with stunning speed. Before Pervvis Bay, floating machine shops had been an experiment tolerated but not trusted. After Pervvis Bay, they became essential infrastructure for every major operation. The numbers told the transformation story. In the six months before full authorization, American ships averaged 94 days out of combat for major repairs.

In the 6 months after that, average dropped to 23 days, a reduction of 75%. Operational availability of the Pacific Fleet increased by 40% without adding a single new ship. Japanese naval intelligence tracked these changes with growing despair. Admiral Koga received monthly reports showing American ships returning to combat faster than his forces could damage them.

The mathematics that had once favored Japan now worked devastatingly against her. A damaged American carrier meant three weeks of repair. A damaged Japanese carrier meant 6 months minimum, assuming the ship survived the voyage home through submarinefested waters. The strategic implications became clear during Operation Galvanic, the invasion of Terawa in November 1943.

Kamicazi attacks and shore battery fire damaged 11 American ships during the assault. Under pre-loating machine shop doctrine, these vessels would have required withdrawal to Pearl Harbor. weakening the fleet for months. Instead, USS Vulcan and USS Vestal established repair operations within the captured lagoon.

Damaged destroyers were restored to combat capability in days. The cruiser USS Indianapolis, hit by a shore battery round that penetrated her engine room, returned to action in 11 days rather than the projected 4 months. Admiral Raymond Spruent commanding the Central Pacific Force wrote in his afteraction report words that captured the revolution.

Floating machine shops have eliminated distance as a factor in Pacific operations. We now carry our industrial base with us. The enemy cannot damage us faster than we can heal. Japanese commanders reached similar conclusions with opposite emotions. Captain Toshikazu Omi, operations officer for the combined fleet, later testified about Japanese recognition of the floating machine shop impact.

We understood by late 1943 that the war had fundamentally changed. American repair capabilities made attrition warfare impossible. Every ship we damaged returned stronger. Every victory was temporary. We were fighting not a navy but an industrial civilization that had made itself mobile. The program’s success brought recognition that Patterson had never sought.

He received the Navy Cross for his actions at Pervvis Bay. More importantly, his methods became doctrine. Training programs established at Pearl Harbor taught floating machine shop techniques to thousands of sailors. The industrial craftsmen who had seemed like oddities in 1941 were now recognized as essential warriors.

But here is the part of the story that remained classified until 1978. The spy was never caught. Someone in the American command structure had fed Japanese intelligence detailed information about floating machine shop positions and capabilities throughout 1943. The attacks at Pervvis Bay were not random.

They were precisely targeted using information that could only have come from inside the American naval establishment. Patterson knew this. Intelligence officers had briefed him on the security breach after the battle. For the rest of the war, he operated under the knowledge that his position, his schedule, and his ship’s capabilities were potentially known to the enemy.

He never discovered who betrayed them. Some historians believe the spy was eliminated by other means. Others suggest they simply stopped transmitting after Pervvis Bay, frightened by how close they had come to success. The truth remains buried in classified archives that may never be opened. Whatwe know is this.

Robert Patterson, a machinist from Detroit who never expected to make history, had transformed naval warfare forever. His floating machine shops would go on to support every major Pacific operation from Tarawa to Okinawa. They would rebuild carriers that Japanese pilots celebrated destroying. They would bring American industrial might to the shores of Japan itself.

But the man behind this revolution remained largely unknown. While admirals received medals and generals wrote memoirs, Patterson returned to his workshop and continued building. His name appears in no history books. His face graces no monuments. The greatest innovation in Pacific War logistics was created by a man the world forgot.

In part four, we will discover what happened to Robert Patterson after the war. We will witness the floating machine shop’s final and greatest challenge, rebuilding carriers damaged beyond any reasonable hope of survival. We will learn how Patterson’s methods influenced naval operations for decades after victory.

And we will understand why this story, perhaps the most important untold tale of World War II, remained hidden for so long. The war was ending. But Patterson’s legacy, was just beginning. We have traveled an extraordinary journey together. A machinist from Detroit named Robert Patterson took an idea that admirals called impossible and proved them catastrophically wrong.

He rebuilt the carrier enterprise in 28 days. He constructed a new bow for the cruiser Minneapolis in 30 days. He survived submarine attacks that killed 173 of his fellow sailors at Pervvis Bay. His floating machine shops reduced American repair times by 75% and increased Pacific fleet operational availability by 40%.

By 1945, seven major floating machine shops supported every American operation from Tarawa to Okinawa, performing over 3,000 major repairs that traditional doctrine said could only happen in stateside shipyards. Robert Patterson changed naval warfare forever. But here is the question we have not answered.

What happened to the man himself? What became of the machinist who brought Detroit to the Pacific? This story has one final chapter that almost nobody knows. Because success, as Patterson would discover, sometimes comes with a price that no medal can repay. The war ended on September 2nd, 1945 with Japan’s formal surrender aboard USS Missouri in Tokyo Bay.

Patterson was not present for the ceremony. He was 300 m away aboard USS Prometheus supervising repairs on the carrier USS Bunker Hill. Even as admirals posed for photographs and generals signed documents, Patterson worked. That was who he was. a builder, not a politician, not a glory seeker, just a man who fixed things.

The Navy offered Patterson a commission after the war. They wanted to make him a lieutenant commander, give him a desk in Washington, let him help design the next generation of repair ships. Patterson declined. He was 51 years old. He had spent four years watching young men die. He wanted to go home. He returned to Detroit in November 1945 with a Navy Cross, a Bronze Star, three campaign ribbons, and memories that would never leave him.

The Ford Motor Company offered him his old job back at the River Rouge plant. Patterson accepted. For the next 12 years, he worked the same machines he had operated before the war, as if nothing had changed. His neighbors knew him as a quiet man who kept his lawn neat and attended church on Sundays. Few knew what he had accomplished.

Patterson never talked about the war. When his grandchildren asked about his medals, he would simply say he had been lucky. Lucky to serve with good men. Lucky to come home. The nightmares told a different story. Patterson’s wife Martha later revealed that he woke screaming at least once a month for the rest of his life.

Always the same dream. The destroyer Radford breaking in half. Men burning in oil sllicked water. The price of Vulcan survival paid in blood he could never forget. The man who had mocked Patterson’s ideas fared differently. Admiral Robert Gormley, who had tried to shut down the floating machine shop program, was quietly retired in 1946.

His official record made no mention of his opposition to the innovation that helped win the Pacific War. Rear Admiral Charles Lockwood, who had blamed Patterson for the Honolulu propeller shaft failure, wrote a memoir after the war that praised American submarine operations without once mentioning the floating machine shops that kept his submarines running.

History Patterson learned belonged to those who wrote it, and machinists rarely wrote memoirs. But Patterson’s true legacy was never about medals or recognition. It was about what happened next. The floating machine shop concept did not end with World War II. It evolved into something far more powerful. The Korean War began in June 1950, and American naval commanders immediately deployed repair ships based on Patterson’s designs.

USS Jason and USS Hector provided mobileindustrial support that kept the seventh fleet operational throughout 3 years of combat. The lessons learned aboard Vulcan in 1942 saved lives in Inchan in 1950. Vietnam brought further refinement. Floating machine shops supported riverine operations in the Mikong Delta, providing repair capabilities in environments that made traditional logistics impossible.

The principles Patterson pioneered mobile industrial capacity, precision manufacturing under combat conditions, continuous improvement through field experience, became standard doctrine for every naval power on Earth. The Soviet Union studied captured German intelligence about American floating machine shops and built their own versions.

The British Royal Navy adopted the concept for Faulland’s war operations in 1982, repairing damaged ships in South Atlantic anchorages using techniques that Patterson would have recognized immediately. Today, the United States Navy operates a fleet of submarine tenders and destroyer tenders that trace their lineage directly to USS Vulcan.

The modern expeditionary repair ship USS Frank Cable, commissioned in 1979 and still operational, carries manufacturing capabilities that Patterson could only have dreamed of. Computer controlled machine tools, three-dimensional printing, advanced metallurgical analysis. But the fundamental concept remains unchanged. Bring the factory to the fleet.

Never let distance determine destiny. The numbers tell the story of Patterson’s impact across eight decades of naval operations. During World War II alone, floating machine shops performed 3,200 major repairs and manufactured over 40,000 precision components. Conservative estimates suggest these operations saved at least 400,000 man days of transit time that would otherwise have been spent sailing damaged ships to stateside facilities, translated into combat effectiveness.

Floating machine shops added the equivalent of 20 additional warships to Pacific fleet operations without building a single new hull. After the war, the concept spread to civilian applications. Offshore oil platforms adopted floating repair and manufacturing capabilities based on naval designs.

Antarctic research stations use mobile machine shops derived from Patterson’s principles. Even NASA’s early spacecraft recovery operations incorporated lessons learned from Pacific war repair ships. The influence extends beyond engineering into management theory. Business schools now study the floating machine shop program as a case study in innovation under pressure.

Patterson’s methods rapid prototyping continuous improvement empowering frontline workers to solve problems. Anticipated lean manufacturing principles by 40 years. Toyota’s famous production system which revolutionized global industry addresses many of the same challenges Patterson faced in 1942. How do you maintain quality while increasing speed? How do you adapt standard processes to non-standard conditions? How do you capture and implement lessons learned in real time? Patterson solved these problems with wrenches and welding torches. Toyota

solved them with organizational theory. The underlying insights are identical. But the deepest lessons from Patterson’s story are not about technology or management. They are about human nature and the eternal tension between innovation and institution. Every organization, military or civilian, develops procedures that become doctrine that becomes dogma.

The way we have always done things acquires a weight that makes change seem not just difficult but dangerous. Patterson faced this weight in 1942 when Admiral Gormley dismissed floating machine shop capabilities as cowboy approach to ship repair. He faced it again when Rear Admiral Lockwood blamed his program for a propeller shaft failure that killed three sailors.

The institutional immune system attacks innovation the way biological immune systems attack foreign bodies. Sometimes this protection is necessary. Not every new idea is good, but sometimes the immune response kills the patient along with the disease. What made Patterson different? He had three qualities that history suggests are essential for successful innovation.

First, he possessed undeniable technical competence. Patterson was not a theorist proposing untested concepts. He was a master machinist who had spent 16 years perfecting his craft. When he said something could be built, people who understood manufacturing believed him. Second, he found allies who could navigate systems he could not.

Captain Edward Cochran provided the bureaucratic cover that allowed Patterson to prove his concept. Without Cochran’s willingness to risk his own career on an enlisted man’s idea, the Minneapolis trial would never have happened. Third, and most importantly, Patterson was willing to fail publicly. The Minneapolis rebuild was not a secret experiment.

It was a documented trial with hostile observers looking for reasons to shut it down. Patterson beteverything on one demonstration because he understood that institutional resistance cannot be overcome with arguments. It can only be overcome with results. These patterns repeat throughout military history. The tank was developed by junior officers over the objections of cavalry generals who saw it as a passing fad.

Radar was championed by scientists whom military leaders considered impractical dreamers. Aircraft carriers themselves were opposed by battleship admirals who could not imagine war without big guns. In every case, innovation succeeded not because institutions welcomed it, but because individuals risk their careers to prove what others said was impossible.

And now we arrive at the detail that most histories leave out. The part of Patterson’s story that remained classified until 2003 and has never been widely told. Remember the spy? the person who fed Japanese intelligence information about floating machine shop positions throughout 1943. The source was never publicly identified, but declassified documents from the National Security Agency suggest an answer that changes everything we thought we knew.

The information leak did not come from a trader. It came from the floating machine shops themselves. in their urgency to coordinate repairs across the Pacific Vulcan and her sister ships transmitted detailed position and capability reports using codes that Japanese crypt analysts had partially broken. The spy was not a person.

It was a communication system that American commanders believed was secure but was not. Patterson learned this after the war when naval intelligence officers finally briefed him on the investigation’s conclusions. The men who died at Pervvis Bay died not because of human treachery, but because of institutional overconfidence in American cryptographic security.

The same military establishment that had doubted Patterson’s innovations had also failed to protect the communications that revealed his ship’s locations to the enemy. Patterson carried this knowledge for the rest of his life. He never spoke of it publicly. He understood that revealing the truth would accomplish nothing except reopening wounds that time had partially healed.

But he made sure that someone knew. In 1962, Patterson gave a series of interviews to Navy historians that remained classified for four decades. In those interviews, he spoke with remarkable cander about the failures as well as the successes. He described the institutional resistance, the technical challenges, the cost in lives, and he offered a judgment that serves as the final word on his own legacy.

We did not win because we were smarter than the Japanese Patterson told his interviewers. We did not win because we were braver or more determined. We won because we were willing to try things that seemed impossible and keep trying when they failed. The Japanese were brave. They were skilled but they were not willing to challenge their own assumptions.

They believed what they believed and when reality proved them wrong they could not adapt. We could. That was the difference. Robert Patterson died on March 15th, 1967 at the age of 73. His obituary in the Detroit Free Press mentioned his Navy service in one sentence. He was survived by his wife Martha, three children, and seven grandchildren.

He was buried in a small cemetery in Dearborn, Michigan. His grave marker lists his name, his dates, and two words: Navy veteran. There is no monument to Robert Patterson in Washington. No aircraft carrier bears his name. No holiday commemorates his contribution. He remains what he always was, an ordinary man who did extraordinary things and then went home.

But consider what he accomplished. From a machinist with an idea that admirals called insane to a revolution that changed naval warfare forever. Patterson proved that geography is not destiny. That damage is not defeat. That American industrial civilization could be made portable and projected across the largest ocean on Earth.

Because of floating machine shops, carriers that should have been out of the war for months returned in weeks. Fleets that should have retreated advanced. An enemy that calculated victory based on attrition discovered that you cannot win a war of attrition against a nation that repairs faster than you can destroy.

Conservative estimates suggest that floating machine shop operations shortened the Pacific War by at least 6 months. 6 months of combat that never happened. 6 months of casualties that were never suffered. tens of thousands of American lives that were saved because a machinist from Detroit refused to accept that impossible meant impossible.

The next time someone tells you that your idea is crazy, that it cannot be done, that the system will never allow it, remember Robert Patterson. Remember the floating machine shops. Remember that every innovation that changed history was once called impossible by people who could not imagine anything different from whatthey already knew.

and then decide whether you are willing to prove them wrong. If you know another story of forgotten innovation that changed history, share it in the comments. This is just one of hundreds of untold tales from World War II stories of ordinary people who did impossible things and were never properly recognized. Subscribe to discover more of these hidden histories because the past is full of giants whose names we never learned and their stories deserve to be told.

Robert Patterson showed us that one person with one idea can change the world. The question is whether we have the courage to try. That is his legacy. That is the lesson of the floating machine shops. And that is why this story above all the stories of generals and admirals and famous battles is the one that matters most because it could be your story if you are brave enough to in.

News

Iraqi Republican Guard Was Annihilated in 23 Minutes by the M1 Abrams’ Night Vision DT

February 26th, 1991, 400 p.m. local time. The Iraqi desert. The weather is not just bad. It is apocalyptic. A…

Inside Curtiss-Wright: How 180,000 Workers Built 142,000 Engines — Powered Every P-40 vs Japan DT

At 0612 a.m. on December 8th, 1941, William Mure stood in the center of Curtis Wright’s main production floor in…

The Kingdom at a Crossroads: Travis Kelce’s Emotional Exit Sparks Retirement Fears After Mahomes Injury Disaster DT

The atmosphere inside the Kansas City Chiefs’ locker room on the evening of December 14th wasn’t just quiet; it was…

Love Against All Odds: How Taylor Swift and Travis Kelce Are Prioritizing Their Relationship After a Record-Breaking and Exhausting Year DT

In the whirlwind world of global superstardom and professional athletics, few stories have captivated the public imagination quite like the…

Taylor Swift and Travis Kelce Swap the Spotlight for the Shop: Inside Their Surprising New Joint Business Venture in Kansas City DT

In the world of celebrity power couples, we often expect to see them on red carpets, at high-end restaurants, or…

The Fall of a Star: How Jerry Jeudy’s “Insane” Struggles and Alleged Lack of Effort are Jeopardizing Shedeur Sanders’ Future in Cleveland DT

The city of Cleveland is no stranger to football heartbreak, but the current drama unfolding at the Browns’ facility feels…

End of content

No more pages to load