The factory floor trembled beneath 10,000 footsteps. In the halflight of dawn, women in coveralls welded wings onto bombers that didn’t yet have names. Across the ocean, in a bunker beneath Berlin, a man studied maps of an empire he believed would last a thousand years.

Unaware that the war had already turned, not on any battlefield, but in the foundaries of a nation he had dismissed as soft. Before we dive in, make sure you’re subscribed. Every week we uncover the stories the world forgot. It began not with thunder but with silence. In the spring of 1940, as German tanks rolled through France with a speed that stunned the world, America watched from across an ocean it still believed was wide enough to keep the war away. The factories of Detroit built cars.

The shipyards of Newport News launched passenger liners. The airfields of Kansas trained crop dusters. In the halls of Congress, isolationist senators promised that American boys would never again die in Europe’s ancient feuds. The Great War, the war to end all wars, had been over for barely two decades, and the scars still achd.

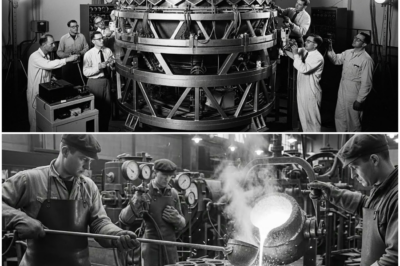

But in a modest office in Washington, a group of men gathered around a table covered in blueprints and production estimates. They were not generals. They were not admirals. They were industrialists, economists, and engineers. men who understood that modern war would not be won by courage alone, but by the cold mathematics of production.

One of them, a quiet automobile executive named William Kudson, placed his finger on a single number that would change everything. 50,000, he said. 50,000 aircraft per year. The room fell silent. It was May 1940. America’s entire air force possessed fewer than 3,000 combat ready planes. The idea of building 50,000 in a single year seemed not ambitious but delusional.

A fantasy disconnected from every reality of steel, rubber, aluminum, and skilled labor. Yet, President Roosevelt, reading the reports from France as the Majino line crumbled and the British Expeditionary Force retreated toward Dunkirk, understood something that others did not. this war would be won or lost in the sky, and the nation that controlled the sky would need an ocean of planes. Roosevelt went further.

In a radio address that crackled through living rooms across the nation, he called for 50,000 planes, not per year, but immediately and then 50,000 more the year after, and more still until the assembly lines ran without end. To a country still emerging from the Great Depression, still nursing its wounds from the last war, still clinging to the dream of isolation, it sounded like madness.

But in the sprawling factories of America, silent giants that had built the cars, the refrigerators, the washing machines of a consumer age, something began to stir. The transformation did not announce itself with fanfare. It crept forward in a thousand quiet decisions. A General Motors plant in Trenton stopped assembling Buick sedans and retoled for aircraft engines.

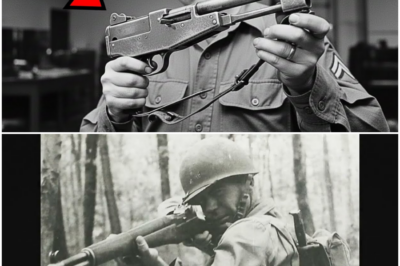

A furniture factory in Grand Rapids began cutting plywood for bomber fuselages. A typewriter manufacturer in Connecticut started stamping out machine gun components. Within months, the entire industrial landscape of America began to shift. Like a sleeping giant rolling over in its sleep, William Kudson, the Danish immigrant who had risen to lead General Motors, became the unlikely architect of this transformation.

Appointed to lead the office of production management, he moved through the country like a man possessed, visiting plants, studying workflows, questioning every assumption. He had built his career on the assembly line, that uniquely American innovation that had made the automobile affordable to millions. Now he would apply those same principles to war.

But aircraft were not cars. A B7 flying fortress contained more than 40,000 individual parts. Its wings stretched over 100 ft. Its four engines generated nearly 5,000 horsepower. Building one required the precision of a watchmaker and the strength of a ship builder. The traditional aircraft manufacturers Boeing Douglas Consolidated produced planes the way artisans built cathedrals slowly, carefully, one at a time.

Their factories were workshops. Their workers were craftsmen. They could produce dozens of planes per month, perhaps a few hundred, but not thousands, not tens of thousands. Nudson understood that to win this war, America would need to break every rule of aircraft manufacturing. The planes would need to be standardized, simplified, designed for mass production rather than perfection.

Components would need to be interchangeable. Subasssemblies would need to be farmed out to hundreds of suppliers. The final assembly would need to move down a line station by station like a Model T. The aircraft companies resisted. Their engineers argued that planes were too complex, too delicate for such crude methods.

Each aircraft needed to be individually calibrated. They insisted. The tolerances were too fine. The stresses too great. Mass production would result in mass casualties. Planes that would fall from the sky, killing their own crews. But Kenudson had seen what American industry could do when it forgot what was impossible.

He had watched Henry Ford turn skilled craftsmen into line workers and quintuple production overnight. He had seen General Motors coordinate thousands of suppliers across the continent to deliver parts that fit together with Swiss precision.

If America could build a car every minute, it could build a bomber every hour. Meanwhile, across the Atlantic, Germany celebrated its victories with parades and speeches. In the summer of 1940, the Luftwafa, the German air force was the most powerful in the world. Its Messid fighters had swept the skies over Poland and France.

Its Stooka dive bombers had broken armies with the screaming terror of their attacks. Herman Guring, the corpulent World War I ace who commanded the Luftvafa, promised Hitler that Britain would fall by autumn. But in the quiet offices of the Reich Air Ministry, a few men studied production reports and felt the first stirrings of unease.

Germany was producing roughly a thousand aircraft per month, a remarkable figure by European standards. But the losses over Britain were mounting. Fighters were being shot down faster than they could be replaced. Bombers returned to base with holes punched through wings and fuselages. Pilots were dying or disappearing into British prison camps.

The arithmetic was becoming uncomfortable. Hitler confident that the war would be over by Christmas saw no reason to strain the German economy with total war production. The factories that built aircraft also built cars for the Vermacht, trucks for the Eastern Front, locomotives for the railways.

Germany was fighting a war, yes, but it was not yet mobilized for the kind of industrial struggle that would consume everything. There would be time, Hitler believed, to increase production later after Britain fell, after the Soviet Union collapsed, after the inevitable victory arrived. It was a fatal miscalculation, though no one in Berlin knew it yet.

Back in America, the first prototype B-24 Liberator bombers began rolling out of the new Willowrun plant near Detroit. The facility itself was a marvel, a single building covering 67 acres with an assembly line that stretched for more than a mile.

It had been designed by Albert Khan, the architect who had created Ford’s Highland Park plant, and it embodied every lesson learned from decades of mass production. Raw materials entered at one end, finished bombers emerged from the other. At peak production, the plant would complete one B-24 every 63 minutes, but that was still in the future. In 1941, as America edged closer to war, the production lines were just beginning to move.

Workers arrived from farms and small towns, many of whom had never seen an aircraft up close, let alone built one. They learned to rivet aluminum skins, install hydraulic systems, mount machine guns and turrets that could rotate 360°. Many of them were women, Rosie the riveters, the posters would call them, stepping into roles that had been closed to them before the war. The learning curve was steep and sometimes deadly.

Early models suffered from structural failures, electrical malfunctions, engines that quit mid-flight. Workers made mistakes, reversed wiring, forgotten bolts, misaligned components. Test pilots climbed into cockpits knowing that they might be flying a machine built by someone who had been working a farm 6 months earlier.

Some of those pilots did not come back, but gradually, impossibly, the system began to work. Engineers simplified designs, eliminating unnecessary complexity. Managers reorganized workflows, creating subasssembly stations where workers could master a single task and repeat it hundreds of times. Quality control inspectors caught errors before they became tragedies.

Training programs turned novices into skilled technicians in weeks rather than years, and the numbers began to climb. By the end of 1941, American factories were producing 3,000 aircraft per month. Not all of them were combat ready. Some went to training schools. Others went to Britain under the lend lease program.

But the infrastructure was in place. The workforce was expanding. And the production lines were accelerating. Then came December 7th. The attack on Pearl Harbor changed everything, though not in the way most people imagine. The shock of that Sunday morning, the burning battleships, the shattered aircraft lined up in neat rows on the airfields, the 2,400 dead, ignited something primal in the American psyche. Isolationism died in the fire.

The debate ended. Every factory, every forge, every foundry would now turn toward a single purpose. Within days, Roosevelt called for 60,000 aircraft in 1942 and double that in 1943. The target seemed impossible. But by now, impossibility had become routine. Auto plants that still produced civilian cars switched entirely to military production.

Civilian air travel was curtailed to free up aluminum. Rubber drives collected scrap to keep tire production alive. The entire economy pivoted toward war. And at the center of that transformation stood the aircraft industry. In California, Douglas Aircraft expanded its plans to employ nearly 100,000 workers.

In Seattle, Boeing turned out flying fortresses around the clock, three shifts a day, seven days a week. In Kansas, Beachcraft built trainers by the hundreds, preparing the flood of young pilots who would fly the bombers being born in Detroit and Long Beach and Fort Worth. The scale was staggering.

A single B7 required 15 mi of wiring, enough sheet metal to roof a dozen houses, and machine tools precise to a thousandth of an inch. Multiply that by thousands of planes. Add the fighters and transports and reconnaissance aircraft. And the logistical challenge became a symphony of coordination involving tens of thousands of suppliers, millions of workers, and industrial capacity that exceeded the entire productive output of the Axis powers combined.

Germany, by contrast, remained stubbornly resistant to total war production. Even as the Eastern front consumed men and machines at a horrifying rate, Hitler refused to fully mobilize the German economy. He feared that asking civilians for too much sacrifice would undermine morale. Better to keep the department store stocked. The cafes opened the illusion of normaly alive.

Albert Spear, who became Minister of Armaments in 1942, fought desperately to rationalize production, to introduce mass production techniques, to coordinate the scattered aircraft factories into something resembling American efficiency. But it was too late.

Germany’s industrial base, powerful as it was, had been designed for a short war, a series of lightning campaigns that would knock out enemies before they could mobilize. The prospect of grinding industrial attrition of a war won not by superior tactics or battlefield brilliance, but by sheer weight of production had never entered the calculus.

By the middle of 1942, American production hit 5,000 aircraft per month. The training fields of Texas and Arizona churned out pilots faster than the planes could be delivered. Bomber crews trained on obsolete models because the new ones were already being shipped overseas. The logistics strained every resource. Not enough teachers, not enough mechanics, not enough spare parts.

But the machine kept expanding, kept accelerating, driven by the terrible knowledge that every day of delay meant another day that Axis forces bombed cities, sank ships, and occupied nations. In the factories, the work became a kind of rhythm. The clang of rivet guns, the hiss of welding torches, the rumble of engines being tested at full throttle.

Workers took pride in their output, chalking messages on bombs destined for Berlin, compliments of the ladies of Willow Run. They worked through exhaustion, through injuries, through the grief of learning that a son or husband had gone down over Germany in a plane just like the one they were building. The human cost of this production is easy to forget. Industrial accidents claimed lives, falls from scaffolding, crushes between machinery, electrocutions.

The factories were dangerous places filled with heavy equipment, volatile materials, and the constant pressure to move faster. But the workers understood what was at stake. Every plane that rolled off the line meant one more weapon in the hands of someone fighting tyranny. Every day of production brought victory one day closer.

By the end of 1942, America had produced 47,000 aircraft. It was not the 50,000 Roosevelt had demanded, but it was close and the trajectory was clear. In 1943, production soared to 86,000. In 1944, it peaked at 96,000, averaging more than 200 aircraft completed every single day.

Germany, struggling under Allied bombing, raw material shortages, and the chaos of a collapsing empire, produced 40,000 aircraft in 1944. Japan managed 28,000. Together, the Axis powers could not match the output of a single nation that had been at peace just 3 years earlier. The numbers tell only part of the story. Behind every statistic stands a human being, a riveter whose hands bled from 12-hour shifts.

A test pilot who climbed into an untried machine knowing that a single engineering mistake could kill him. A mother who worked the night shift while her children slept so she could contribute to a war effort that had taken her husband overseas. The transformation of America into what Roosevelt called the arsenal of democracy was not merely an industrial achievement.

It was a collective act of will, a marshalling of human energy on a scale never before attempted. Consider the town of Ipsilante, Michigan, where the Willowrun plant employed 42,000 workers at its peak. Before the war, Ipsilante had been a quiet college town of 12,000 people. Suddenly, it found itself struggling to house, feed, and transport a population that had quadrupled overnight.

Workers lived in hastily built dormitories and converted barns and trailer parks that stretched for miles. They commuted on special trains and buses that ran around the clock. The infrastructure groaned under the strain, but somehow it held. Inside the plant, the diversity of the workforce would have been unthinkable just years earlier. White women from rural Michigan worked alongside.

black migrants from the south who had traveled north seeking opportunity and escape from Jim Crow. The war did not erase America’s racial divisions, discrimination, remained a toxic presence even in the factories, but it created spaces where competence mattered more than background. A woman who could drive rivets faster and cleaner than anyone else earned respect on the line. Regardless of what doors remained closed to her outside the factory gates, the aircraft themselves evolved as production accelerated.

Early B7s were beautiful but temperamental machines, prone to mechanical failures and vulnerable to fighter attack. By 1943, the B7G model incorporated hundreds of improvements learned from combat experience. additional machine gun positions, upgraded engines, self-sealing fuel tanks that could absorb bullet strikes without exploding. Each modification required retooling factories, retraining workers, redesigning components.

Yet, the production lines barely slowed. American industry had learned to iterate at speed to incorporate lessons from the battlefield into the factory floor in weeks rather than months. The P-51 Mustang fighter, perhaps the war’s most elegant aircraft, embodied this marriage of design and production.

Originally developed in just 117 days to meet a British requirement, the Mustang was good, but not exceptional until someone had the idea of replacing its Allison engine with a British Rolls-Royce Merlin. The transformation was extraordinary.

With the Merlin engine, the P-51 became the first Allied fighter capable of escorting bombers all the way to Berlin and back. It could outfight anything Germany put in the sky. And crucially, it could be mass-roduced. North American Aviation, the company that built the Mustang, delivered more than 15,000 of them during the war.

At peak production, they completed one P-51 every 60 minutes, a fighter plane with a top speed of 440 mph. Equipped with six machine guns and enough range to fly from England to Poland, built faster than a skilled carpenter could frame a house. Across the Pacific, this production avalanche played out in a different theater, but with similar mathematics. Japan, an island nation with limited natural resources and an industrial base a fraction the size of America’s had gambled that a quick strike at Pearl Harbor would the USPacific fleet long enough for Japan to consolidate its conquests and force a

negotiated peace. The gamble almost worked. In the months after Pearl Harbor, Japanese forces rolled across Southeast Asia and the Pacific with stunning speed. But Japanese Admiral Yamamoto, who had studied at Harvard and understood American industrial might, reportedly warned his colleagues that Japan had awakened a sleeping giant. He knew what the production figures meant.

Japan could build excellent aircraft. The Zero Fighter was arguably the best carrier-based fighter in the world in 1941, but it could not build them in sufficient numbers to replace losses. Japanese pilots were superbly trained, but when they died, they took their expertise with them.

There was no deep reserve of trained replacements. No flood of aircraft to absorb losses and keep fighting. American strategy in the Pacific reflected this industrial advantage. Island hopping campaigns were not just about geography.

They were about establishing airfields ever closer to Japan, bringing the entire weight of American production to bear. Every island captured meant another base where B29 superfortresses could land, refuel, and strike the Japanese home islands. Every month brought more planes, more pilots, more bombs. The B-29 itself represented a staggering achievement of engineering and production.

It was the most complex aircraft of the war with pressurized crew compartments, remotec controlled gun turrets, and engines so powerful they frequently caught fire. Early models were plagued with problems. engines that overheated, electrical systems that failed, structural issues that caused catastrophic failures in flight.

The first B-29 crews had mortality rates that rivaled infantry assault units. Yet, Boeing and its subcontractors persisted, fixing problems one by one while simultaneously ramping up production. By 1945, nearly 4,000 B29s had been built. Each one costing more than a warship. each one capable of carrying 10 tons of bombs across distances that would have seemed impossible at the war’s beginning. They firebombed Tokyo. They mined Japanese harbors.

They photographed every inch of the Japanese coastline in preparation for an invasion that ultimately never came because two B29s Inola Gay and Boxcar carried atomic bombs instead. Back in Europe, the air war had evolved into a grinding campaign of attrition. By 1944, American and British bombers flew missions involving a thousand aircraft at a time, escorted by hundreds of fighters, targeting factories, rail yards, oil refineries, and cities. The human cost was staggering on both sides.

German civilians died by the hundreds of thousands in bombing raids. Allied bomber crews faced odds that made survival a matter of grim luck. Complete a tour of duty, 25 missions over Germany, and you beat odds that killed or captured more than half of the men who tried. But the arithmetic was inexurable.

Germany shot down Allied bombers by the hundreds. But the Allies replaced them by the thousands. The Luftwaffa produced aces who shot down dozens, even hundreds of enemy aircraft. But for every ace, there were a 100 German pilots killed in their first weeks of combat.

Overwhelmed by the sheer numbers they faced, German jet fighters, the Me262, a revolutionary aircraft that could have changed the course of the air war, arrived too late and in too few numbers to matter. Germany had the engineering brilliance but lacked the production capacity and crucially the fuel to keep its aircraft flying. By 1945, the skies over Germany belonged entirely to the Allies. Bombers flew in daylight without significant opposition.

Fighter bombers strafed anything that moved on German roads and railways. The Luftwafa, once the terror of Europe, had been ground down not by superior tactics, but by sheer material exhaustion. When Germany surrendered in May 1945, American production did not slow. It pivoted entirely toward Japan.

The invasion of the Japanese home islands planned for November 1945 would require aircraft in numbers that dwarfed anything yet seen. Production schedules called for over a 100,000 aircraft in 1945 with factories preparing to build even more in 1946. The planners estimated American casualties in the hundreds of thousands, perhaps more than a million if the Japanese fought with the fanaticism they had shown on islands like Ewima and Okinawa. The atomic bombs, whatever one thinks of their use, ended that calculus.

Japan surrendered in August 1945 and with stunning abruptness, the production machine that had taken years to build simply stopped. Contracts were cancelled overnight. Workers received pink slips by the thousands. Factories that had run three shifts a day fell silent. The Willowrun plant, which had built more than 8,000 B24 Liberators, closed its doors and eventually became an automobile factory again. The human reckoning of this production miracle is complex and uncomfortable.

Yes, American factories built the weapons that defeated fascism, that liberated concentration camps that ended the war, but they also built the weapons that incinerated cities, killed civilians by the hundreds of thousands, and introduced humanity to the atomic age. The B29s that dropped leaflets over Japan also dropped incendiaries that created firestorms hot enough to melt steel.

The precision with which America built its aircraft was matched by the precision with which it destroyed. Yet to focus only on destruction misses something essential about what happened in those factories. The workers who built a 100,000 planes did not do so out of blood lust.

They did so out of a belief, imperfect, sometimes naive, but genuine, that they were defending civilization against forces that would extinguish it. They worked themselves to exhaustion, not because they loved war, but because they wanted it to end. Every plane completed brought victory one day closer, brought their brothers and sons and husbands home one day sooner.

The veterans of those production lines rarely spoke of their work in heroic terms. When asked about it years later, they shrugged, downplayed their contributions, redirected credit to someone else. “Just doing my job,” they’d say. We all did what we had to do. But in those modest responses lies something profound about the American experience of World War II.

The war was won not by supermen but by ordinary people who did extraordinary work because the moment demanded it. Consider the legacy that production triumph left behind. After the war, America emerged as a superpower not merely because it had prevailed militarily but because it had demonstrated productive capacity that exceeded the rest of the world combined.

The Marshall Plan which rebuilt Europe flowed from that same industrial abundance. The commercial aviation industry which would shrink the world in the decades to come. Built upon the production techniques and engineering advances pioneered during the war. The suburbs that spread across America in the 1950s were built by workers who had learned their skills in war plants.

The highways that connected those suburbs were designed by engineers who had planned logistics for moving bombers across continents. Even the Cold War arms race reflected lessons learned in those factories. When the Soviet Union detonated its first atomic bomb in 1949, America’s response was not merely to build more bombs, but to build production infrastructure capable of building them by the thousands.

The nuclear arsenal that defined the second half of the 20th century emerged from the same industrial logic that had produced 100,000 aircraft. prepare for war by building the capacity to wage it on a scale no enemy can match. But there is a darker legacy too, one that the workers who built those planes could not have foreseen.

The industrial logic of World War II production, the belief that victory belongs to whoever can build the most fastest has shaped every conflict since. The Vietnam War saw America drop more bombs than were used in all of World War II, believing that sheer tonnage would break the enemy’s will. It did not.

The Iraq War saw American military might, unmatched in human history, prevail easily on the battlefield, yet struggle for years in occupation. Production, it turns out, can build weapons, but cannot build peace. Still, on a cool morning in September 1945, as workers filed out of the Willowrun plant for the last time, as the assembly lines fell silent and the lights dimmed, they had earned the right to feel proud. They had built the weapons that won the war.

They had proven that democracy, chaotic and inefficient as it sometimes seems, could outproduce dictatorship when the stakes were high enough. They had shown that free people working voluntarily for a common cause were more productive than slave labor or ideological fanaticism. Germany had underestimated America.

Hitler in his bunker beneath Berlin as the Red Army closed in never understood that the war had been lost years earlier in the factories of Michigan and California and Kansas. He believed until the end that wonder weapons, jets and rockets and secret projects would turn the tide.

He never grasped that modern war is not won by miracles, but by mathematics, by the unglamorous arithmetic of how many planes you can build, how many pilots you can train, how many times you can replace losses, and keep fighting. Japan, to its credit, understood faster. Japanese leaders touring the rubble of their cities in August 1945, saw in the devastation not merely military defeat, but industrial annihilation.

They had fought bravely, sometimes fanatically, but they had been overwhelmed by an opponent who could absorb every loss and return stronger. The kamicazi pilots who crashed their planes into American ships understood in their final moments that for every ship they sank, America would build three more. The futility of that arithmetic made their sacrifice no less tragic.

In the decades since, historians have debated endlessly the decisions of World War II, whether bombing cities was justified, whether the atomic bombs were necessary, whether alternative strategies might have achieved victory at lower cost. These are questions without easy answers, questions that deserve serious moral consideration.

But one fact remains beyond dispute. America built a 100,000 planes while its enemies slept. And that production miracle changed the course of history. Walk through the Air Force Museum in Dayton, Ohio, or the Air and Space Museum in Washington, and you can see the artifacts of that transformation. A B7 hangs from the ceiling, its silver skin still bearing the scars of flack damage over Germany.

A P-51 Mustang, painted in the bright colors of an AC’s personal aircraft, crouches on the floor like a predator. A B29 Superfortress, enormous and imposing, dominates an entire gallery. These are not merely machines. They are monuments to the human capacity for both creation and destruction, for sacrifice and survival, for the terrible ingenuity we bring to the task of war. The workers who built them are mostly gone now.

The last Rosie the Riveters, the last welders and engineers and test pilots are fading into history. Soon there will be no one left who remembers what it felt like to work those shifts, to hear those rivets, to watch those planes roll off the line knowing that someone’s son would fly it into combat. Their story will become purely historical.

A chapter in textbooks, a subject for documentaries. But their achievement endures. They prove that ordinary people given purpose and leadership and opportunity can accomplish the extraordinary. They showed that democracy, for all its messiness, possesses reserves of strength that tyranny can never match.

They demonstrated that production, unglamorous, statistical, industrial production, matters as much in war as valor on the battlefield, and they paid a price for that knowledge. The factories that built those planes also broke bodies, strained families, and claimed lives. The war they helped win killed millions, and left scars that have never fully healed.

Victory came at a cost that seems almost incomprehensible from the safe distance of decades. We remember the triumph, but must never forget the sacrifice. On a factory floor in Michigan, on a spring morning in 1945, a woman removed her welding mask and looked at the B-24 Liberator she had just finished.

It was the last plane her shift would complete before the contracts were cancelled, before the war ended, before everyone went home. She ran her hand along the rivets she had placed, thousands of them over the past 3 years, each one a tiny act of defiance against tyranny. She did not know where this plane would fly, who would crew it, whether it would come home.

She knew only that she had built it as well as she could, that it represented her contribution to a cause larger than herself. That bomber never saw combat. The war ended before it could be deployed. It was sold for scrap, melted down, perhaps reborn as part of a Chevrolet or refrigerator or a swing set in someone’s backyard.

But in its brief existence, it stood for something important. For the moment when America set aside its divisions and doubts and built the tools that freed a world. The lesson of those 100,000 planes echoes still. It whispers that production matters, that organization matters, that the unglamorous work of building things is as vital to victory as the glory of combat.

It reminds us that wars are won not just by heroes, but by people willing to do hard, repetitive, exhausting work, because it needs doing. It teaches that democracy’s greatest strength is not its ideals, though those matter, but its ability to mobilize free people toward common purpose. And it warns us, if we are willing to listen, that the capacity to build also brings the responsibility to choose wisely what we build.

The factories that saved democracy in 1945 could just as easily serve tyranny if we are not vigilant. The production systems that defeated fascism could be turned toward oppression. The choice always is ours. In the end, the story of America’s aircraft production in World War II is not really about planes at all.

It is about what humans can accomplish when history demands everything they have to give. It is about the strange alchemy that transforms ordinary people into something greater than themselves. It is about the terrible price of freedom and the even more terrible cost of losing it.

100,000 planes built in factories that did not exist when the war began. Flown by pilots who were not yet born when Hitler invaded Poland. Used to defeat an empire that believed itself invincible. And then when victory came, those factories closed. Those workers went home and America tried to return to the peaceime dreams it had interrupted.

But the world had changed and the people who built those planes had changed too. They had learned what they were capable of. They had discovered reserves of strength and determination they did not know they possessed. They had proven that free people working together could defeat any tyranny if they were willing to pay the price.

That knowledge, more than any weapon, more than any aircraft or bomb or ship, was the true victory of those years. We carry it still. A legacy from those who worked in darkness so we might live in light. If you love untold stories from history’s darkest hours, subscribe and join us on the next mission through

News

Inside Willow Run Night Shift: How 4,000 Black Workers Built B-24 Sections in Secret Hangar DT

At 11:47 p.m. on February 14th, 1943, the night shift bell rang across Willow Run. The sound cut through frozen…

The $16 Gun America Never Took Seriously — Until It Outlived Them All DT

The $16 gun America never took seriously until it outlived them all. December 24th, 1944. Bastonia, Belgium. The frozen forest…

Inside Seneca Shipyards: How 6,700 Farmhands Built 157 LSTs in 18 Months — Carried Patton DT

At 0514 a.m. on April 22nd, 1942, the first shift arrived at a construction site that didn’t exist three months…

German Engineers Opened a Half-Track and Found America’s Secret DT

March 18th, 1944, near the shattered outskirts of Anzio, Italy, a German recovery unit dragged an intact American halftrack into…

They Called the Angle Impossible — Until His Rifle Cleared 34 Italians From the Ridge DT

At 11:47 a.m. on October 23rd, 1942, Corporal Daniel Danny Kak pressed his cheek against the stock of his Springfield…

The Trinity Gadget’s Secret: How 32 Explosive Lenses Changed WWII DT

July 13th, 1945. Late evening, Macdonald Ranchhouse, New Mexico. George Kistakowski kneels on the wooden floor, his hands trembling, not…

End of content

No more pages to load