The intelligence report arrived at Luftvafa headquarters in Berlin on the morning of February 8th, 1944. Major Hinrich Bower, a career officer who had spent 15 years in military aviation before the war, was assigned to review it. The document was thin, maybe 20 pages, bound in the standard gray cover used for captured enemy materials. His orders were simple.

Verify or discredit the contents. What he read in those pages would haunt him for the remainder of his life. The report claimed that American factories had produced 47,000 aircraft in 1943 alone. 47,000 in 12 months. Bower read the number three times, certain there had been a translation error.

Perhaps it meant 4700, or perhaps the figure represented all Allied production combined. But no, the breakdown was specific, detailed, organized by manufacturer and aircraft type. Boeing alone had produced nearly 7,000 B17 flying fortresses. Consolidated had manufactured over 9,000 B-24 Liberators. The list continued across dozens of companies, each one churning out hundreds or thousands of combat aircraft.

Bower’s hand trembled slightly as he set down the first page. He had spent the previous year coordinating production reports for the Luftvafa. He knew exactly what German industry was capable of achieving. In 1943, even with Albert Spear’s rationalization programs and the total mobilization of German society for war, the Reich had produced approximately 25,000 aircraft.

This had been celebrated as a triumph, proof that German engineering and organizational discipline could overcome material disadvantages. If you’re enjoying this deep dive into the story, hit the subscribe button and let us know in the comments from where in the world you are watching from today.

And yet this document suggested that America, a nation that had been at peace until December 1941, that was supposedly soft and undisiplined, that was fighting a two ocean war while maintaining a civilian economy, had produced nearly double Germany’s output in a single year, while also building the world’s largest navy, while supplying Britain and the Soviet Union with thousands of additional aircraft under lend lease, while their citizens ill drove private automobiles and bought consumer goods.

The mathematics made no sense, or rather they made perfect sense, and that was what terrified Bower. Because if these numbers were accurate, then the war was already decided, not by tactics or courage or fighting spirit, but by simple industrial arithmetic. Germany could not win a war of attrition against an opponent with twice its production capacity.

And if the trend continued, if American output was still increasing and every indicator suggested it was, then the disparity would only grow worse. Bower had joined the Luftvafer in 1928 when Germany was still restricted by the Versailles treaty and military aviation existed only in secret.

He had watched the service grow from a clandestine organization training in the Soviet Union to the most modern air force in Europe. He had witnessed the triumph of the Condor Legion in Spain, the devastating effectiveness of close air support in Poland and France, the early victories against the Soviet Union. The Luftvafer had been invincible, a precision instrument wielded by men who understood that discipline and skill could overcome any obstacle. That confidence had been built on certain assumptions.

The first was that Germany would fight relatively short wars. Blitzkrieg lightning war was not just a tactical doctrine but an economic necessity. Germany lacked the raw materials for prolonged industrial warfare. Quick victories were essential. The second assumption was that Germany’s enemies would be roughly comparable in industrial capacity.

France had been wealthy but poorly organized. Britain was formidable but small. The Soviet Union was vast but primitive. America had always been the outlier. the variable that didn’t fit comfortably into German strategic planning. But certain comforting conclusions had been reached. American society was divided, soft, lacking in marshall spirit. Their military was small and inexperienced.

Their industry was geared toward consumer goods, not weapons. Democracy was inherently inefficient, unable to mobilize as effectively as a totalitarian state. These weren’t mere propaganda. They were analytical conclusions reached by intelligent officers looking at the available evidence. Bower himself had believed these things.

Why wouldn’t he? The evidence seemed to support them. America had sat out the first two years of the European War. When they finally entered after Pearl Harbor, their initial performance in North Africa had been mediocre. Their equipment, while sometimes impressive, showed the hallmarks of a peacetime military that had never faced serious combat.

German pilots who encountered American fighters in early 1943 reported that while the aircraft were rugged, the pilots were inexperienced and cautious. But that had been nearly a year ago. The air war over Europe had transformed since then. The bombers kept coming in ever larger formations. The fighter escorts ranged deeper into German territory.

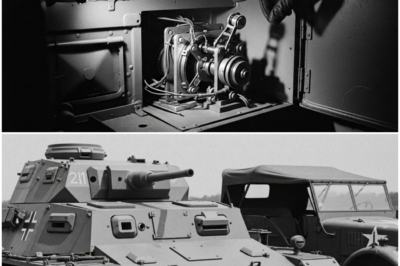

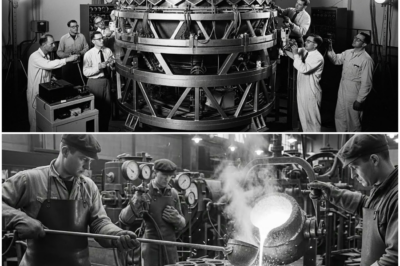

The combat losses that should have forced a pause in operations never materialized because the Americans simply replaced every aircraft shot down, every crew killed or captured. Bower opened the report to the detailed breakdowns. The Willowrun plant in Michigan occupied 67 acres under a single roof. The main assembly line stretched over one mile long.

At peak production, this one factory completed a B-24 Liberator heavy bomber every 63 minutes, every hour. One complete 4engine bomber containing over 400,000 individual parts equipped with 10 50 caliber machine guns capable of carrying 8,000 lb of bombs across 1,500 m. He had toured German aircraft factories.

He understood the complexity of building modern combat aircraft, the precision machining required for engines, the specialized aluminum alloys, the electrical systems, hydraulic systems, weapons systems, the coordination of thousands of components from hundreds of suppliers. Building a single aircraft was an achievement. Building one per hour was impossible. Except the Americans were doing it right now.

As he sat in this office trying to comprehend the implications, another B-24 was rolling off the Willowr run line, and another would follow 63 minutes later, and another after that. Every hour of every day, an endless stream of heavy bombers flowing from a single factory that employed 42,000 workers and operated on principles borrowed from automotive assembly lines.

Bower turned to the section on aluminum, a production. This was the foundation of everything. You couldn’t build aircraft without aluminum. And aluminum production was limited by electrical power and raw materials. Germany produced approximately 250,000 tons of aluminum per year despite strenuous efforts to expand capacity.

The Americans were producing over 900,000 tons annually, nearly four times German output. They had so much aluminum that they were using it for applications that German engineers would never consider disposable fuel tanks, ground vehicles, even packaging materials. The electrical power required for aluminum smelting was staggering. Each ton required approximately 15,000 kwatt hours.

The Americans were generating electricity on a scale that Europe had never approached. The Grand Koulie dam alone produced more power than several German cities combined and Grand Koulie was just one of dozens of massive hydroelect electric projects completed during the previous word decade. The Tennessee Valley Authority had transformed an entire region into an industrial powerhouse.

The Americans had been building the infrastructure for total war throughout the 1930s, though they hadn’t called it that at the time. A knock interrupted his analysis. Hedman Ernst Vber entered carrying additional files. Vber was 31, a mechanical engineer before the war, now assigned to technical intelligence analysis.

He had the perpetually exhausted look of someone who worked with numbers that refused to make sense. Hair major, the interrogation summaries you requested. Bower gestured toward the chair across from his desk. The office was cramped like everything else in Berlin by early 1944. The city was showing the strain of years of war-damaged buildings awaiting repair, diminished food supplies, the constant tension of waiting for the next RAF night raid. Outside his window, Berlin looked gray and tired.

What did you find? Bower asked. Veber opened his folder, but his expression suggested he already knew Bower wouldn’t like the answer. We have conducted detailed interrogations of 63 captured American airmen over the past 3 months. Bomber crews primarily, though also some fighter pilots, the accounts are remarkably consistent.

They could be maintaining a unified story, standard resistance to interrogation. Respectfully, hair major, I do not believe so. These men are not trained intelligence operatives. They are pilots and bombarders and radio operators. Most are 20 to 25 years old from civilian backgrounds.

When we ask them about American production, about their training facilities, about replacement aircraft, there is no hesitation, no careful phrasing. They speak about abundance the way one might speak about the weather. It is simply the reality they know. Bower leaned back in his chair. Give me an example. Weber consulted his notes. 3 weeks ago we interrogated the pertis crew of a B7 shot down near Stoutgart.

The pilot was a 23-year-old named Thompson from a place called Nebraska. Agricultural background. University education. Before he flew combat missions, he trained at a facility in Texas. I asked him to describe it. Weber looked up from his notes. Hair major. He said the training base had over 300 B7s at any given time. 300 just for training.

He said new aircraft arrived weekly, sometimes daily. When they damaged an aircraft during training exercises, which happened frequently, as student pilots are not always precise, they simply replaced it. The idea of aircraft shortage never occurred to him. He could have been exaggerating. That was my first thought.

But then I cross-referenced his account with others. A co-pilot from Indiana described a similar facility with hundreds of training aircraft. A bombardier from California mentioned that his training base had full machine shops that could manufacture spare parts on site rather than waiting for supply chains.

They describe an infrastructure that treats aircraft the way our supply system treats rifles as abundant replaceable tools rather than precious assets. Bower stood and walked to the window. Outside, a convoy of trucks moved slowly down the street, likely carrying supplies to the eastern front. Each truck was precious, carefully maintained, irreplaceable if lost.

The contrast with whatever was describing felt like a gulf between different worlds. Tell me about pilot training, Bower said quietly. The American program requires approximately 200 flight hours before a pilot reaches a combat unit. 200 hours. Hair major. Our current program has been reduced to as few as 100 hours, sometimes less, because we cannot spare the fuel and aircraft for more extensive training, Weber continued, his voice taking on a clinical tone that made the horror more pronounced. “And the numbers are staggering. The Americans are training

thousands of pilots simultaneously at dozens of facilities.” A captured navigator mentioned that his training class had over 200 students, just one class at one base. He estimated there were 15 or 20 such bases operating at similar scales. How many new pilots are they producing based on the interrogations and documentary evidence? Approximately 4,000 to 5,000 per month across all training programs.

pilots, navigators, bombarders, gunners, all trained to a level that matches or exceeds our pre-war standards, which we can no longer maintain. Bower returned to his desk and picked up the production report. The numbers had been disturbing when viewed in isolation. Combined with Wayer’s intelligence on training infrastructure, they became apocalyptic.

Because the Americans weren’t just building aircraft, they were building a complete system. For every bomber rolling off the production line, there were trained crews waiting. For every fighter produced, there was a pilot with 200 hours of flight time ready to fly it. And behind them were more in training, and behind them more being recruited from a population of 130 million people.

Germany had 80 million people and millions were already committed to the Eastern Front, to occupation duties, to maintaining industrial production. The Luftvafa was losing experienced pilots faster than they could be replaced, and the replacement pilots arrived with inadequate training. The attrition mathematics were straightforward and brutal. There is something else, Weber said, his voice dropping.

something less tangible but perhaps more significant. Continue, the American prisoners, when they speak about the war, they do not speak like soldiers of a nation fighting for survival. There is no desperation, no sense of existential threat. They want the war to end so they can return home. They are confident it will end in Allied victory.

But this confidence is casual, matter of fact. They speak about defeating Germany the way one might speak about completing a difficult but manageable project. Weber leaned forward. One pilot, when asked if he feared German fighter attacks, said that he was mostly worried about flack, not because our fighters weren’t dangerous, but because there were quote fewer of them every week.

Another mentioned that his squadron had been told to expect replacements within days whenever losses occurred, and those replacements always arrived on schedule. They have internalized an expectation of abundance that is completely foreign to our experience. Bower had served on the Eastern Front in 1941. He had seen the Luftvafer at its peak, supporting the rapid advance into Soviet territory. The pilots had been confident then, convinced of German superiority.

But that confidence had been built on tangible evidence they were winning. They shot down more enemy aircraft than they lost. They supported ground forces that captured hundreds of miles of territory. The Americans had a different kind of confidence. It wasn’t based on tactical superiority or current victories.

It was based on a deep certainty that their industrial system would eventually overwhelm any opposition. They could afford losses. They could afford to learn from mistakes. They could afford to pursue strategies that German forces operating on narrower margins could never attempt. What is the current assessment of American aircraft quality? Bower asked. Weber pulled out another file. Mixed.

The B17 and B-24 are robust designs, heavy defensive armament, significant bomb loads, excellent range. They can absorb substantial battle damage and continue flying. Our pilots respect them. The escort fighters were initially inferior. The P-38 had problems at high altitude.

The P-47 was effective but had limited range. And now now they have the P-51 Mustang range sufficient to escort bombers deep into Germany. Performance that matches or exceeds our best fighters and they are producing them by the thousands. Her major, we are reaching a point where numerical superiority creates qualitative advantages.

When bomber formations include 800 or 1,000 aircraft with 400 fighter escorts, our tactical skill becomes irrelevant. We cannot engage forces of that size and survive. Bower thought about the young pilots currently defending German airspace. Many were teenagers rushed through abbreviated training programs sent into combat with barely enough experience to handle their aircraft, let alone fight effectively.

They faced American bomber streams protected by fighters flown by pilots who had trained for months under ideal conditions. The experienced German pilots, the veterans of Poland and France, and the Eastern Front, they were dying.

being shot down over Germany, where rescue might be possible, but where they would simply be sent up again the next day, being killed over occupied France or Belgium, too far from home for recovery, or increasingly being transferred east to face the Soviet air forces, which were themselves growing stronger as American and British supplies poured in through Merman and Persia. Every lost veteran was irreplaceable.

the institutional knowledge, the combat experience, the accumulated skill gone. The Americans could lose a 100 pilots in a month and replace them with a 100 more who were nearly as well-trained. Germany lost a dozen experienced pilots, and the quality of the entire force declined. If you find this story engaging, please take a moment to subscribe and enable notifications.

It helps us continue producing in-depth content like this. Have you reviewed the production projections for 1944? Bower asked. Yes, her major. If current trends continue, the Americans will produce between 70 and 80,000 aircraft this year. We will be fortunate to match our 1943 output of 25,000. And that assumes no major disruption to our factories from bombing or resource shortages. 70 to 80,000 aircraft.

The number was so large it lost meaning. Bower tried to visualize it. Imagined aircraft filling airfields stretching to the horizon. Tried to imagine the raw materials, the factories, the workers, the fuel, the ammunition, everything required to not just build, but also operate such a force.

Is the high command aware of these figures? Weber’s expression became carefully neutral. Various departments have received portions of the intelligence. Whether anyone has assembled a comprehensive assessment, I cannot say. There is resistance to accepting information that contradicts strategic assumptions. Of course, there was because accepting these numbers meant accepting that Germany could not win a prolonged war against America.

And if Germany couldn’t win against America, and America was committed to unconditional surrender, then the entire strategic position was hopeless. Better to question the intelligence, to argue that the numbers were exaggerated, to insist that German fighting spirit and superior tactics would somehow overcome material disadvantage. Bower had been a loyal officer for 15 years.

He had never questioned orders, never doubted the leadership. But sitting here with undeniable evidence of industrial catastrophe, he felt something crack inside his certainty. Not his loyalty that remained, but his confidence in ultimate victory, the belief that German determination would eventually prevail that was harder to maintain when confronted with arithmetic. What do you recommend? Her major way asked quietly.

What could he recommend? That Germany immediately sued for peace? That would be considered defeatism, possibly treason. Does German industry somehow match American output? Impossible. The resource base didn’t exist. The factory capacity couldn’t be built quickly enough. The electrical power wasn’t available.

Can new tactics be developed to counter numerical superiority? Tactics could only do so much when outnumbered 3 or 4 to one. We document everything, Bower said. Finally. We compile a comprehensive report with all available evidence. We present it to the appropriate authorities. We do our duty as intelligence officers. And if the report is ignored, then at least we will have fulfilled our responsibility to provide accurate information. What others choose to do with that information is beyond our control.

Weber nodded and gathered his files. At the door, he paused. her major, may I ask a personal question? Go ahead. When did you stop believing we would win? Bower considered the question carefully. It deserved an honest answer. I think it was gradual, small things that accumulated. The Eastern Front stabilized instead of collapsing.

The British held on when they should have negotiated. The Americans entered the war and did not collapse under their first defeats. Each event was explainable in isolation, but together they formed a pattern. He gestured at the intelligence report. This just makes it explicit. Puts numbers to what we were afraid to acknowledge.

But the doubt that started earlier, probably for many of us, though few would admit it. After Weber left, Bower sat alone with his thoughts. The office was quiet except for the distant sounds of the city traffic, construction crews repairing bomb damage, the ordinary noise of life continuing despite everything. Berlin had been bombed repeatedly now, and yet people still went to work, still tried to maintain normal routines.

Humans were remarkably adaptable. He pulled out a sheet of paper and began drafting his report. The words came slowly at first, then faster as the structure took shape. He documented the American production figures, cross-referenced them with interrogation data, compared them against German capabilities. He was careful to present only verifiable facts to avoid speculation or editorializing.

The numbers would speak for themselves to anyone willing to listen. The report grew to 30 pages, then 40, then 50. He included appendices with detailed breakdowns by aircraft type, production facility, training base locations. He cited specific interrogations, referenced captured documents, noted areas where information remained incomplete, but where the overall pattern was clear. It was late evening when he finally finished.

His desk lamp cast shadows across the pages, covered in his precise handwriting. Outside, darkness had fallen. Somewhere over Germany, RAF bombers were likely beginning their nightly missions. In Britain, American bomber crews were sleeping or preparing for tomorrow’s daylight raids. In factories across America, assembly lines continued running.

Bower thought about his son, currently serving with an anti-aircraft battery near Hamburg. I am 18 years old, still believed in final victory, still thought that German spirit and courage would somehow prevail. How did you tell your son that the war was already lost, that his sacrifice would change nothing, that the best he could hope for was survival until the inevitable end? You couldn’t.

You could only hope he survived long enough to see the end, to return home when the fighting finally stopped, to have a life after this catastrophe ended. Bower sealed the report in an envelope marked for the chief of Luftvafa intelligence. Whether it would be read, whether it would be believed, whether it would change anything, he had no control over those outcomes. He had done his duty.

He had reported the truth as best he could determine it. The factory that couldn’t exist was producing aircraft by the tens of thousands. The training program that seemed impossible was generating thousands of new pilots every month. The industrial system that should have been overwhelmed by war was instead expanding, growing stronger, accelerating its output, and Germany, for all its military excellence and tactical brilliance and fighting spirit, had no answer to it.

Bower turned off his desk lamp and sat in darkness for a moment. Tomorrow he will submit the report. Tomorrow the war will continue. Tomorrow young men would die in aircraft that couldn’t be replaced fast enough while fighting an enemy whose losses barely mattered because the replacements were already waiting.

He thought about the American pilot from Nebraska, trained at a facility with 300 aircraft, confident of victory, not because of current battlefield success, but because of unshakable faith in his nation’s productive capacity. That faith had been justified. The numbers proved it. Germany had prepared for a warriors war and found itself in an accountant’s war.

It had brought spirit to a contest of steel and steel was winning. The morning after submitting his report, Bower received orders to travel to Recklin, the Luftbuffer’s primary testing facility located north of Berlin. The summons came without explanation, marked only as urgent technical consultation. He packed a small bag and caught the afternoon train. watching the winter landscape slide past his window.

Forests dusted with snow. Small towns that looked untouched by war. Farmers still working their fields despite everything. Germany looked peaceful from a train window. The war existed elsewhere in distant cities being bombed on battlefields in Italy and Russia and France. Reclin was different. Here the war was immediate and tangible.

The facility existed to evaluate captured enemy equipment, to test new German designs, to push the boundaries of aviation technology. Bower had visited twice before, both times to review technical assessments of Soviet aircraft. The base had a strange atmosphere, part laboratory, part military installation, staffed by engineers and test pilots who spoke about aircraft the way other men spoke about art or literature.

He was met at the station by a young lieutenant who drove him through the base perimeter to a large hanger set apart from the main testing areas. Armed guards stood at the entrance. Whatever was inside warranted serious security. Hair Major Bower. A tall man in civilian clothes approached as Bower entered the hanger. I am Dr. Carl Steinhoff.

Thank you for coming on short notice. I was given very little information about why I am here. Yes, that was intentional. What I am about to show you is being kept under strict confidence. Your report on American production capacity reached my desk yesterday. It raised questions that this evaluation may help answer.

Steinhoff led Bower deeper into the hangar, and there, surrounded by measuring equipment and technical personnel, sat an American P-51 Mustang fighter. The aircraft was largely intact, showing battle damage, but still recognizable. The distinctive profile, the bubble canopy, the long nose housing, the Rolls-Royce Merlin engine built under license by Packard.

She came down near Osnarbrook 3 weeks ago, Steinhoff explained. Pilot survived and was captured. The aircraft was damaged but recoverable. We have been conducting a complete technical evaluation. Bower walked around the fighter slowly. He had seen photographs, had read intelligence reports, but seeing the actual machine was different.

The Mustang was sleek, purposeful, every line suggesting speed and efficiency. German fighters had a brutal elegance to them, the angular messes 109, the muscular Fauler Wolf 190. This American fighter looked almost delicate by comparison, though Bower knew that appearance was deceptive. “What have you found?” he asked. Steinhoff opened a thick folder. “That is a complex question.

The Mustang is an exceptional aircraft, but not in the ways one might expect. Let me show you.” They approached a workbench where the fighter’s engine had been partially disassembled. Steinhoff gestured to various components. The Merlin engine is superb. We knew that already. British design, American manufacturer. But look at how it is installed.

The entire engine mounting system uses standardized bolts and quick release mechanisms. A trained crew can remove this engine and install a replacement in under 2 hours. 2 hours. We timed it. By contrast, changing an engine on a Meshachesmidt 109 takes the better part of a day, sometimes longer depending on conditions.

The Americans have designed for field maintenance in ways we have not fully considered. Steinhoff moved to another section of the fighter. Look at the panel access points. Zeus fasteners throughout quarter turn fasteners that can be opened without tools. Every major component is accessible. The electrical systems are color-coded.

The hydraulic lines are clearly marked. A moderately trained mechanic can service this aircraft quickly and efficiently. You are saying it is stable, easier to maintain. I am saying it is designed from the beginning with maintenance in mind. German aircraft are engineered for performance first and maintenance is addressed secondarily. This aircraft integrates both considerations from the initial design.

It is a philosophical difference that has significant operational implications. Bower understood what Steinhoff wasn’t quite saying directly. If American fighters could be serviced faster, they could fly more missions. If components could be replaced quickly, battle damage was less likely to ground aircraft for extended periods.

Maintenance efficiency multiplied combat effectiveness. What about the construction? Bower asked. Steinhoff led him to where sections of the Mustang’s skin had been removed. Aluminum alloy throughout, but notice the manufacturing techniques. This is not handfitted sheet metal. These panels are stamped using massive presses produced to tolerances that allow interchangeability.

Any panel from any P-51 will fit any other P-51. We do not build aircraft this way. Why not? because it requires enormous capital investment in tooling, massive hydraulic presses, precision dyes, automated forming equipment, the sort of industrial infrastructure that takes years to build and only makes economic sense if you are producing thousands of identical units. The Americans are producing thousands of identical units.

We are still essentially crafting individual aircraft. Bower thought about the Willow Run factory, about the assembly line producing a bomber every hour. That kind of production required exactly this approach. Standardization, interchangeable parts, manufacturing processes borrowed from mass production industries.

There is more, Steinhoff continued. He pulled out several components, valves, switches, and small mechanical parts. Notice anything unusual about these? Bower examined them. They looked wellmade, precisely machined. They appear standard. Look at the markings. Bower held a valve assembly up to the light.

Stamped on the side was a manufacturer’s code and the notation Delo. Another component was marked Bendix. A third showed Sperry. These components were made by different companies, Steinhoff explained. Not aircraft manufacturers, automotive parts suppliers, electronics companies, industrial equipment manufacturers. The Americans have distributed production across their entire industrial base.

This valve was probably made in a factory that normally produces automobile components. That switch might come from a facility that makes radio equipment for civilian markets. And it works reliably, perfectly, because the Americans have developed precision manufacturing standards that allow components from different suppliers to integrate seamlessly. They have industrialized warfare in a way we have not fully grasped.

Steinhoff walked to a whiteboard where someone had sketched production comparisons. Your report documents their total aircraft output, but the deeper story is how they achieve it. They are not just building more. They are building differently. They have created a production system that can scale almost infinitely because it draws on their entire industrial economy.

While we concentrate production in specialized aircraft manufacturers exactly, which makes sense for peace time or short wars. But in an extended conflict, their approach proves superior. When we bomb a messes factory, we damage our only source for that aircraft.

When the British bomb an American factory which they cannot reach, but hypothetically the production is distributed across dozens of facilities, many of which can substitute for each other. Bower walked back to the Mustang and placed his hand on the wing. The aluminum was cool, smooth, and precisely formed. This single aircraft represented not just American engineering skill, but an entire production philosophy, an industrial system that Germany could not match or even fully replicate.

There is one more thing, Steinhoff said quietly. Something we discovered that troubles me more than any performance specification. He led Bower to a small side office where several technical manuals lay spread across a desk. These are the pilot’s operating handbook, the maintenance manual, and the parts catalog, all captured with the aircraft.

Bower picked up the pilot’s handbook. It was professionally printed, clearly written, illustrated with detailed diagrams. He flipped through pages describing startup procedures, emergency protocols, performance characteristics. Everything was organized logically, presented clearly. Notice the publication date. Steinhoff said.

Bower checked the cover. October 1943, just 4 months old. Now look at the parts catalog. The catalog was enormous. Hundreds of pages listing every component of the aircraft with detailed specifications and part numbers. It was printed on good quality paper, bound professionally, illustrated with technical drawings that must have required hundreds of hours to produce.

They are producing technical documentation at the same scale as the aircraft themselves. Steinhoff said, “Every pilot receives a handbook. Every maintenance crew receives manuals. Every supply officer receives parts catalogs. The documentation alone represents an industrial effort that would strain our entire publishing industry.” Bower set down the manuals and looked at the Mustang again. It was just one aircraft.

One example of one fighter type among dozens being produced. And yet the system behind it, the factories, the supply chains, the training programs, the documentation, the maintenance procedures or the spare parts production, all of it represented an approach to warfare that operated on a completely different scale than what Germany had prepared for.

The pilot who flew this aircraft, Bower said, what did he say during interrogation? Steinhoff consulted another file. His name is Lieutenant James Patterson, 24 years old from a place called Michigan. He has been in Europe for 6 weeks. This was his eighth combat mission. Before entering the military, he was studying mechanical engineering at university. His training took 11 months from enlistment to combat assignment. 11 months? Yes.

And he is typical, not exceptional. The Americans have created an education and training pipeline that produces technically competent air crew at industrial scale. Patterson understood his aircraft thoroughly, knew its capabilities and limitations, and could perform basic field maintenance himself if required. He spoke about his squadron’s logistics support with casual confidence.

Spare parts arrived regularly. Maintenance crews were well equipped. Fuel was never a concern. Did he expect to survive the war? Yes. He said his chances were good because his squadron had excellent support and his aircraft was reliable. He believed the war would end in Allied victory within the year. This was not bravado. It was simply his expectation based on everything he had experienced.

Bower walked to the hangar entrance and looked out across the Recklin test facility. Somewhere on these grounds, German engineers were working on jet aircraft, on rocket powered interceptors, on advanced designs that might give Germany a technological edge. Projects like the Mi262 jet fighter represented genuine innovations, aircraft that could potentially outperform anything the Allies had.

But even if those projects succeeded, even if Germany produced revolutionary aircraft, could they be built in sufficient numbers? Could they be maintained in field conditions? Could pilots be trained fast enough? The American system wasn’t built on technological breakthroughs.

It was built on industrial capacity, on logistics, on the ability to produce reliable equipment in overwhelming quantities. Dr. to Steinhoff. If Germany had started preparing for this war in 1933 when the party came to power, if we had focused all our efforts on building the industrial base to fight America, could we have matched their capacity? Steinhoff was quiet for a long moment. That is a political question as much as a technical one, hair major.

But speaking purely as an engineer, no. Even with a decade of preparation, I do not believe we could match American industrial capacity. The resource base is too different. They have access to raw materials we lack. Their electrical power generation, their transportation networks, their machine tool industry.

These were built over decades before the war. And their population is larger. Their territory is vast and secure from bombing. Their economy was wealthy enough to invest in massive infrastructure projects during the depression. So we were always going to lose this kind of war. If the war became industrial rather than operational, yes, our only chance was quick victories before American industry fully mobilized.

By late 1942, that window had closed. Bower nodded slowly. It was the answer he had expected, the conclusion his own analysis had reached. But hearing it confirmed by someone of Steinhoff’s expertise made it real in a way that numbers on paper had not. Thank you for showing me this, Bower said. It provides important context for the intelligence assessments.

Hair major, may I speak candidly, please? Your report will not change anything. The people who need to understand these realities, they will not want to hear them. There is too much invested in continuing the current strategy, too many careers built on optimism, too much ideological commitment to the idea that willpower conquers material disadvantage.

You think I am wasting my time. I think you are doing your duty by reporting accurately. But I also think the system is not designed to process information that contradicts its fundamental assumptions. We will continue fighting with increasing desperation, building wonder weapons that arrive too late in insufficient numbers, and telling ourselves that final victory is still possible because the alternative, accepting that we have already lost, is psychologically unbearable for those in command. They shook hands and Bower left

the hanger. The drive back to the train station took him past other facilities at Recklin wind tunnels, engine test stands, experimental workshops. All of it represented German technical excellence, genuine engineering achievement. But excellence and achievement were not enough when facing an opponent who could produce overwhelming quantity while maintaining acceptable quality.

The train back to Berlin was crowded with soldiers on leave, with civilians traveling on various war business, with the ordinary traffic of a nation still functioning despite years of conflict. Bower found a seat and watched the landscape pass once more. Somewhere over these fields and forests, American bombers were probably flying at this very moment.

Tomorrow they will return and the day after and the day after that until Germany’s industrial capacity was destroyed, its transportation systems crippled, its ability to wage war eliminated through simple attrition. He thought about Latutenant Patterson, the Michigan engineering student turned fighter pilot.

Thought about the confidence in Patterson’s voice when he discussed his chances of survival, his certainty of Allied victory. That confidence was justified. Not because American pilots were better fighters. German pilots with equivalent experience often showed superior tactical skill. Patterson’s confidence was justified because behind him stood an industrial system that could replace any loss, repair any damage, supply any need, and against that system, German courage and tactical excellence could achieve local victories, but could never win the larger war. Back in Berlin, Bower

delivered his technical addendum to the original report. He documented what Steinhoff had shown him at Wlin, added analysis of American production philosophy versus German approaches, included photographs and measurements of the captured Mustang.

The report grew to 80 pages, comprehensive and thoroughly documented. He heard nothing for 3 weeks. Then a summons arrived, a meeting with senior Luftvafa staff to discuss intelligence assessments. Bower prepared carefully, organized his materials, and anticipated questions. Perhaps someone was finally ready to confront reality.

The meeting was held in a conference room that had once been elegant, but now showed the wear of wartime austerity. 15 officers attended, ranging from majors to generals. Bower presented for 45 minutes, walking through production figures, training data, technical assessments. He kept his tone professional, his conclusions measured. He let the numbers speak for themselves. When he finished, there was silence.

Then a colonel in his 50s spoke up. These American production claims, they seem exaggerated, propaganda, perhaps designed to discourage us. her Oburst. The figures are cross-referenced from multiple independent sources, captured documents, prisoner interrogations, observations by agents in neutral countries, even pre-war American government publications.

The consistency suggests accuracy, but the scale seems impossible. No industrial system could produce aircraft at those rates while also building ships, tanks, everything else. That was my initial reaction as well, Herobust. But the evidence supports it. The Americans have created an industrial base that operates on a scale we have no equivalent for.

Their approach to manufacturing allows, a general interrupted, Major Bower, we appreciate your thoroughess. However, we must be careful not to let enemy propaganda influence our assessments. The Americans have every reason to exaggerate their capabilities. With respect, hair general. This is not propaganda. We have examined captured American aircraft.

The construction techniques, the manufacturing quality, the documentation systems, they all indicate a production system operating at exactly the scale the numbers suggest. Another officer spoke up. Even if we accept these production figures, they do not account for combat effectiveness. We have shot down thousands of American aircraft.

Our pilots regularly achieve kill ratios in our favor in individual encounters. Yes, hair obstust. But the strategic situation is that they can afford their losses and we cannot. They replace every aircraft shot down within days. We struggle to replace ours within weeks or months. The general leaned forward.

Major Bower, your report seems to suggest that Germany cannot win this war. Is that your conclusion? The room went very quiet. This was the dangerous moment where honesty could be interpreted as defeatism. Bower chose his words carefully. Her general, “My conclusion is that we cannot win an extended war of attrition against the combined industrial capacity of America, Britain, and the Soviet Union while also fighting on multiple fronts.

Our only path to victory would have been through quick operational successes that forced a negotiated peace before enemy industry fully mobilized. That window appears to have closed. Appears to have closed. The general’s voice was cold. Are you suggesting we should seek peace terms? I am an intelligence officer, hair general, not a policy maker.

I present information. What decisions are made based on that information is far above my authority. But you believe the situation is hopeless. Bower met the general’s eyes. I believe the situation is extremely difficult.

I believe we face an enemy with material advantages that cannot be overcome through tactical excellence alone. I believe we need to understand the true scope of what we are facing. The general stood. What we are facing, Major, is a test of German will and courage. Yes, the enemy has material advantages. They have always had material advantages. But we have fought before when outnumbered and won. We will do so again.

Hair, General, the scale of the scale does not matter if we refuse to be defeated. History is made by men of will, not by factories and production lines. Germany has always prevailed through superior spirit and discipline. This war will be no different. The meeting ended shortly after. Bower’s report was accepted formally, filed, and effectively ignored.

As he left the building, he passed a poster on the wall showing a determined German soldier with the caption, “Victory or bulcheism, there is no alternative.” The message was clear. Questioning victory was equivalent to accepting defeat and accepting defeat was treason. That evening Bower sat in his small apartment and wrote a letter to his son.

He kept it carefully neutral, full of fatherly concern and encouragement. He did not mention the production figures or the intelligence reports or the meeting with senior staff. What would be the point? His son was serving his country, doing his duty. Knowing the strategic situation was hopeless, would not change his responsibilities or his danger.

Instead, Bower wrote about ordinary things, family news, memories from before the war, hopes for the future. He told his son to be careful, to trust his training, and to come home safely. And beneath all the conventional sentiments, beneath the forced optimism that the war demanded, there was a deeper message. Survive. Just survive.

Because the war would end eventually, one way or another, and those who survived would have the chance to rebuild something from the wreckage. He sealed the letter and placed it on his desk to mail in the morning. Outside his window, Berlin was dark, observing blackout protocols against RAF night raids.

The city had become a place of shadows and muted sounds as if it were already fading into history. Bower thought about the Willowrun factory, about assembly lines running day and night, about B24 bombers rolling off the production line every hour. Thought about training bases in Texas with 300 aircraft. thought about Lieutenant Patterson’s casual confidence that spare parts would always arrive on schedule.

Thought about an industrial system so vast and so efficient that it treated warfare as just another production problem to be solved through engineering and organization. Germany had prepared for a warriors war and found itself in an industrialists war. The mismatch was total. And now in early 1944, with the outcome mathematically inevitable, if strategically unacceptable to acknowledge, Germany would continue fighting, not because victory was possible, but because admitting defeat was impossible.

The next morning, Bower returned to his office and resumed his duties. There were more intelligence reports to review, more captured documents to analyze, more interrogations to supervise. The work continued because it had to continue. Even if his assessments were ignored, even if the strategic leadership refused to confront reality, the duty remained to document that reality as accurately as possible.

Vber came by in the afternoon with new interrogation summaries. More American bomber crews shot down over Germany. More accounts of abundant training, reliable logistics, confident expectations of victory. The stories were monotonously consistent. Any response to your report? Hair major way asked. It was received, acknowledged. That is all.

Wayber nodded understanding immediately. So we continue. We continue. They worked through the afternoon documenting evidence that would be filed and forgotten, building a comprehensive picture of enemy capabilities that no one in authority wanted to see clearly. It was futile work in many ways. But it was also necessary because someone needed to record what was actually happening even if that record would only matter later after the war ended when historians tried to understand how Germany had misread its strategic position. so completely the numbers were there had always been there. American

industrial capacity was documented before the war began. The potential was observable. But seeing that potential and understanding its implications for a prolonged conflict, those were different things. And the Nazi system built on ideology and willpower and marshall virtue was structurally incapable of admitting that some problems could not be solved through determination alone.

So Germany would fight on, would produce wonder weapons that arrived too late, would send increasingly young and poorly trained pilots into hopeless battles, would sacrifice cities and populations in a war that had already been decided by industrial arithmetic. Not because the leadership was stupid or cowardly, but because the alternative, accepting a defeat that invalidated everything the regime stood for, was psychologically and politically impossible.

Bower worked late that evening finishing a technical assessment of American bomber tactics. His office was quiet, the building mostly empty. Somewhere in the distance, he heard the air raid sirens begin their whale. Another RAF night raid begins. He continued working, used to the routine now. The raids would continue.

The bombers would keep coming, and tomorrow, American B7s and B-24s would return in daylight. He thought about his conversation with Steinhoff at Reclin about the doctor’s prediction that nothing would change. Steinhof had been right. The system was not designed to process information that contradicted its assumptions. Truth was subordinate to necessity, and the necessity was to maintain the fiction of possible victory because without that fiction, the entire structure collapsed.

By mid 1944, the reality would be undeniable, even to the most optimistic observers. American and British forces would invade France. Soviet armies would continue advancing from the east. German cities would burn under roundthe-clock bombing. The industrial base would crumble. The transportation networks would fail.

And still the war would continue for another year, consuming hundreds of thousands more lives in a cause that had been lost before most of those soldiers even entered service. Bower had done his duty. He had reported accurately, documented thoroughly, analyzed honestly. The fact that his work made no difference did not change its necessity.

Someone had to maintain intellectual honesty even when honesty was strategically irrelevant. Someone had to document what was actually happening, even if no one wanted to hear it. The numbers did not lie. 300,000 American aircraft by wars end against 120,000 German. The disparity was total, the implications clear, the outcome inevitable. The factory that should not exist was real.

The production system that seemed impossible was operating. The industrial advantage that ideology insisted could be overcome through willpower was proving decisive, and Major Hinrich Bau sat in his office in Berlin documenting the arithmetic of defeat while the bombs fell outside and the war ground toward its inevitable conclusion. Thank you for watching.

For more detailed historical breakdowns, check out the other videos on your screen now.

News

Inside Willow Run Night Shift: How 4,000 Black Workers Built B-24 Sections in Secret Hangar DT

At 11:47 p.m. on February 14th, 1943, the night shift bell rang across Willow Run. The sound cut through frozen…

The $16 Gun America Never Took Seriously — Until It Outlived Them All DT

The $16 gun America never took seriously until it outlived them all. December 24th, 1944. Bastonia, Belgium. The frozen forest…

Inside Seneca Shipyards: How 6,700 Farmhands Built 157 LSTs in 18 Months — Carried Patton DT

At 0514 a.m. on April 22nd, 1942, the first shift arrived at a construction site that didn’t exist three months…

German Engineers Opened a Half-Track and Found America’s Secret DT

March 18th, 1944, near the shattered outskirts of Anzio, Italy, a German recovery unit dragged an intact American halftrack into…

They Called the Angle Impossible — Until His Rifle Cleared 34 Italians From the Ridge DT

At 11:47 a.m. on October 23rd, 1942, Corporal Daniel Danny Kak pressed his cheek against the stock of his Springfield…

The Trinity Gadget’s Secret: How 32 Explosive Lenses Changed WWII DT

July 13th, 1945. Late evening, Macdonald Ranchhouse, New Mexico. George Kistakowski kneels on the wooden floor, his hands trembling, not…

End of content

No more pages to load