June 27, 1944. The Port of Sherborg, France. Colonel Alden G. Sibli of the 1,56th Port Construction and Repair Group stands on the shattered remains of K to France. His engineering survey team fanning out across what should be one of Europe’s finest deep water harbors.

The morning sun reveals a landscape of calculated destruction that takes his breath away. This isn’t battle damage. This is systematic annihilation. Sibli’s boots crunch across twisted metal and broken concrete as he makes his way toward the harbor basin. What he sees defies immediate comprehension. 27 ships, freighters, tugs, even a floating dry dock lie scuttled in precise positions across every navigable channel. The Germans hadn’t simply sunk vessels randomly.

They had positioned each hull with mathematical precision to create an interlocking barrier of steel that would take months to clear. Two massive 90ton gantry cranes, each the size of a four-story building, have been toppled directly into the main shipping channel. Their twisted girders creating an underwater obstacle course that no survey team can safely approach.

The harbor walls themselves have been demolished with surgical precision. Every 100 meters, massive demolition charges have blown chunks of masonry the size of automobiles into the water. The breakwater, 3 km of solid stone that took French engineers 40 years to build, has been breached in 17 separate locations.

But it’s the smaller details that reveal the true scope of German thorowness. Every ballard has been cut away at the base with acetylene torches. Every electrical connection has been severed and the copper wire removed. Every water mane has been destroyed. Every warehouse roof has been collapsed.

The lock gates that separate the inner basins from the outer harbor have been blown completely off their hinges and rest at the bottom of the channel. Even the harbor master’s office has been booby trapped. Three of Sibli’s demolition experts are currently diffusing charges placed beneath what remains of the floor.

The official German declaration delivered by General Carl Wilhelm von Schlleben upon his surrender the previous day echoes in Sibli’s mind. I have left you the wreckage of a port that will require 6 months to restore. If you possess the materials and labor, you do not possess them. The harbor is worthless. Sibli pulls out his field notebook and begins his preliminary assessment.

Around him, engineering officers shout measurements and coordinates. Divers prepare to descend into the murky water. The clock has already started. The Allied armies pushing inland from Normandy are consuming supplies faster than the beaches can deliver them. Without a functioning deep water port, the entire offensive could grind to a halt within weeks.

The mathematics are simple and brutal. Sherborg must open, and it must open now. The journey to this moment of devastation had begun exactly 3 years earlier when Adolf Hitler issued Fura directive number 40 on March 23rd, 1942. The document was explicit. Fortresses would be created along the Atlantic Wall, and should any fall to the Allies, they must be rendered completely useless for a minimum of 6 months.

Cherborg, with its position as the closest major French port to England, received special attention. The man who would orchestrate Sherborg’s destruction arrived in April 1944. Corvett and Capitane Walter Henkah commanded the sea commandant Normandy, the German naval command responsible for coastal installations. Henkah was not a combat officer.

He was an engineer who had studied civil engineering at the technical university of Berlin before the war. His orders from Admiral Theodore Cranky were unambiguous. Prepare Sherborg for total destruction should the fortress fall. Henkah approached the task with methodical precision. Throughout May 1944, as D-Day preparations intensified across the English Channel, his teams worked around the clock implementing a demolition plan that would be studied by military engineers for decades. The operation carried the mundane bureaucratic

designation Hoffen vernikong plan 4, harbor destruction plan 4. The first phase involved the placement of underwater obstacles. Beginning on May 15th, 1944, German engineers sank the 8,000 ton freighter SS Portland exactly 200 m from the entrance to the Grande Rod, the outer harbor.

Over the following weeks, 26 additional vessels followed. Each sinking was precisely calculated using tide tables and baimetric charts. The goal was not simply to block channels, but to create underwater obstacles that would damage any Allied vessel attempting to navigate past them. The second phase targeted the port infrastructure itself.

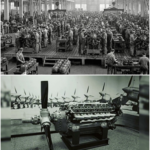

German demolition teams installed over 500 separate charges throughout the harbor complex. Each charge was carefully positioned for maximum structural effect. The two gantry cranes, Crane Gustav and Crane Heinrich as they were known locally, received special attention. Each crane weighed approximately 90 tons and stood 25 m tall.

German engineers cut through their support structures with precision charges designed to topple them directly into the main channel. The third phase focused on denial of services. Every electrical transformer was destroyed. Every water pump was disabled. The sewage system was collapsed. Fuel storage tanks were ruptured and set ablaze.

The cold storage facilities essential for preserving food supplies had their refrigeration equipment systematically demolished with sledgehammers. Even the Harbor Lighthouse had charges placed inside its base, though these would ultimately fail to detonate. The execution of this plan began on June 21, 1944.

As American forces of 7th Corps under Major General Jton Collins began their assault on the fortress city, Henkah’s teams worked methodically following a precise timetable. Each demolition was logged with German efficiency, date, time, location, explosive type, and anticipated damage assessment. The final demolitions occurred between June 25 and June 26 as German forces retreated into the Arsenal area of the city for their last stand. At 300 p.m.

on June 25, Crane Gustav was toppled. At 3:15 p.m., Crane Heinrich followed. Between 400 p.m. and 6:00 p.m., the lock gates were destroyed in sequence. Throughout the night, ships were scled at 20inut intervals. When General von Schlleban surrendered on June 26 at 1:15 p.m., he did so with professional pride in his engineering staff’s accomplishment. The fortress had fallen faster than expected.

Hitler had demanded it hold until July 15, but the harbor had been destroyed exactly as ordered. In Fon Schlleben’s final report to OB West, the German command for the Western Front, he noted the port facilities have been rendered unusable for an estimated period of 6 to 8 months, assuming the enemy possesses adequate salvage equipment and labor, which intelligence suggests they do not.

Radio broadcasts from Paris celebrated the achievement. The Anglo-Americans have captured a corpse of a port. One announcer declared, “They will find only ruins where they expected salvation for their offensive.” In Berlin, Marine High Command assessed the Cherberg demolition as exemplary and recommended Henkah for the Knights Cross for his thoroughess.

The award would be approved on July 24, by which time the assumptions underlying that commenation would be proven catastrophically wrong. The German confidence in their demolition work was not baseless optimism. It rested on decades of engineering doctrine and recent historical precedent. During World War I, retreating German forces had systematically destroyed Belgian ports at Zebbruga and Ostand in 1918, rendering them unusable for the final 6 months of the war.

In 1943, as Allied forces advanced through Italy, German engineers had demolished the port of Naples so thoroughly that Allied engineers required three full months to restore minimal functionality. The Naples example was particularly instructive. When the US Fifth Army captured Naples on October 1, 1943, they found a port destroyed with the same methodical precision later employed at Sherberg.

German demolition teams had sunk 130 vessels in the harbor. They had destroyed every crane. They had demolished the breakwaters and collapsed the warehouses. Allied engineers, despite throwing enormous resources at the problem, didn’t restore full port capacity until January 1944. 90 days of grinding salvage work.

The pattern repeated at Polarmo, Sicily, where German engineers sank 47 vessels and destroyed the harbor facilities before the city fell on July 22nd, 1943. American engineers required 6 weeks to achieve even limited operations. At Salerno, hastily destroyed port facilities took 3 weeks to restore to minimal function. Each success reinforced German confidence in demolition as a strategic weapon.

The Creeks marine developed increasingly sophisticated techniques. Time delayed charges that would detonate days after Allied occupation. Booby traps attached to salvage equipment. Mines positioned to damage recovery vessels. The doctrine was codified in official manuals with precise instructions.

Which structures to demolish first, how to position scuttled vessels for maximum obstruction, optimal charge placement for permanent damage. Intelligence assessments supported this confidence. German reconnaissance had noted that Allied port construction companies, while welle equipped, were relatively small units. The 1,56th port construction and repair group that would face Cherborg, numbered fewer than 2500 men.

German analysis calculated that such a force, even working around the clock, would require 12 to 16 weeks to clear the harbor and restore basic functionality. More conservative estimates extended to 24 weeks. The assessment made a critical assumption that Allied engineering capabilities operated within the same resource constraints as German forces.

German port reconstruction efforts were limited by chronic shortages of equipment, skilled labor, and raw materials. If German engineers needed 3 months to restore a destroyed port and they had experience doing exactly that in the east, then surely American engineers would need at least as long. This assumption permeated every level of German planning.

When OB West calculated supply timelines for the Normandy campaign, they factored in 6 months before Sherberg could meaningfully contribute to Allied logistics. When German forces planned their defensive lines in eastern France, they assumed adequate time to prepare positions before Allied supplies through Cherburgg enabled a major offensive. When Yubot command allocated submarines to attack Atlantic convoys, they calculated that ports in Britain would remain the primary Allied supply route through December 1944.

But the assumption rested on a fundamental misunderstanding of American industrial capability and engineering doctrine. German planners had observed American forces in Italy working with expeditionary resources. What the Americans could ship across the Atlantic and Mediterranean. They had not witnessed what American engineers could accomplish when the full industrial might of the United States was brought to bear on a single problem.

That revelation would begin within hours of Colonel Sibli’s initial survey. By the afternoon of June 27, less than 24 hours after the German surrender, the scope of the American response began to take shape. Colonel Sibli’s preliminary report reached Major General John CH Lee, commander of the communications zone, the US Army’s logistics command in Europe, at his headquarters in London at 4:30 p.m. Lee read the assessment once, then read it again.

The estimated timeline for restoring the port, 90 days minimum, 120 days probable. Lee picked up the telephone and connected to Supreme Headquarters Allied Expeditionary Force. His message was tur Sherborg situation critical. Request maximum allocation of port construction assets and priority shipping for heavy salvage equipment.

What followed was a mobilization that demonstrated the true nature of American logistical superiority. While German engineers had spent weeks preparing Sherborg’s destruction, American logistics officers had spent months preparing for exactly this scenario. The 1056th port construction and repair group was only the beginning.

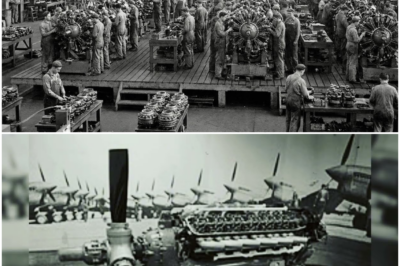

Within 48 hours, the 1057th port construction and repair group arrived from England. The 1060 followed on June 30. The 1055th docked on July 2. By July 5, more than 11,000 specialized engineering troops were operating in Sherburgg, a force nearly five times the size of the German garrison that had defended the city.

But manpower alone wouldn’t clear 27 scuttled ships and 500 tons of underwater debris. The Americans needed equipment on a scale that German planners hadn’t imagined possible. On June 29, the first salvage vessels departed from Southampton and Portland. They carried equipment that represented the cutting edge of maritime engineering.

200 ton floating cranes, compressed air pumping stations capable of delivering 5,000 cubic feet per minute, specialized underwater cutting equipment, and experimental sonar mapping gear developed by the US Navy specifically for harbor clearance operations. The nerve center of the operation was established in a partially destroyed warehouse on the K defrost. Commodore William A.

Sullivan, a US Navy salvage specialist who had overseen the Pearl Harbor cleanup after December 7, 1941, took command of all marine operations. His assistant, Commander Edward Ellburg, had literally written the book on naval salvage. His technical manual, On the Bottom, was required reading at Annapapolis.

Sullivan’s first decision shocked even the experienced engineers around him. We’re not clearing the ships sequentially, he announced at the first planning meeting on June 28. We’re working all channels simultaneously. The conventional approach to harbor clearance was methodical.

Clear one channel completely, establish a supply line, then expand operations. Sullivan threw out the rule book. He divided Cherborg into eight sectors, assigned salvage teams to each, and ordered simultaneous operations across the entire port complex. It was aggressive to the point of recklessness, and it worked.

The greatest challenge lay in the main shipping channel where Crane Gustav and Crane Heinrich created an underwater maze of twisted steel. German engineers had assumed these obstacles would require weeks of careful cutting and removal. On July 1, Lieutenant Commander Raymond Sullivan, no relation to the Commodore, descended in a diving bell to survey the Rex. What he found changed everything.

The cranes had toppled in such a way that their main support structures remained largely intact beneath the water. Rather than cutting them apart piece by piece, Sullivan proposed something unprecedented. Use the massive floating cranes to simply lift the entire structures out of the water in one piece. It’s never been done with objects this size, one engineer protested. Nothing about this operation follows precedent, Commodore Sullivan replied. Make it work.

On July 4th, 1944, Independence Day, a symbolism not lost on the American cruise, two 200 ton floating cranes positioned themselves over the submerged Crane Gustav. Divers worked throughout the morning attaching specialized lifting cables at six points along the structure. At 2 p.m., the order was given. The floating crane’s engines roared to maximum power.

For 3 minutes, nothing seemed to happen except the protesting groan of steel cable under impossible tension. Then, impossibly, the water began to ro. At 2:04 p.m., the top of Crane Gustav broke the surface, seawater cascading off its frame. By 2:30 p.m., the entire 90ton structure hung suspended between the two floating cranes. By 400 p.m.

, it rested on a barge bound for a salvage yard. German reconnaissance pilots photographing the harbor on July 5 radioed back reports that were initially dismissed as hallucinations. American engineers, they claimed, had removed one of the main channel obstacles in a single day. Luftvafa intelligence demanded confirmation.

The photographs told an unmistakable story. One crane gone, the other being rigged for lifting. Crane Heinrich was extracted on July 6th using the same technique. The main shipping channel was clear, but the scuttled vessels presented different challenges. The Americans employed a technique developed after Pearl Harbor.

Seal the ship, pump it full of compressed air, and force it to the surface. Traditional salvage doctrine called for careful assessment of each wreck before attempting recovery. The Americans worked faster. Divers descended, identified major hole breaches, welded patches over them using underwater arc welding equipment, pumped compressed air into the hole, and stepped back.

On July 8, the 4,000 ton freighter SS Renault broke the surface after being submerged for 2 weeks, water streaming from every opening. By July 10, eight additional vessels had been raised. By July 12, the main channels were navigable. Throughout this period, parallel operations attacked every other aspect of the port’s destruction.

Electrical engineers from the 357th Engineer General Service Regiment ran 40 m of new power lines. In 6 days, Navy CBS repaired lock gates by fabricating replacement components in shipboard machine shops. Army engineers bulldozed debris into the water to create temporary qua where none existed. The 1060th Port Construction and Repair Group used explosives to blast new channels through rubble that Germans had spent weeks positioning.

The pace was relentless, operating 24 hours a day under flood lights that turned night into day. German observers watching from inland positions reported that Cherborg Harbor never went dark, a constellation of work lights visible from 20 km away. On July 16th, 1944, at 11:00 a.m., exactly 20 days after Colonel Sibli’s initial survey, the Liberty ship SS John J. Montgomery sailed through the main channel and docked at Quay to France.

By 400 p.m., Steadors were unloading her cargo, 5,000 tons of ammunition, medical supplies, and rations. The impossible had been accomplished. To understand how American engineers achieved what German planners deemed impossible requires understanding the fundamental difference in American military logistics doctrine.

This philosophy didn’t emerge spontaneously in 1944. It was the product of two decades of development that began in the aftermath of World War I. In 1919, the US Army established the Army Industrial College specifically to study the relationship between industrial capacity and military effectiveness. The college’s founding principle was revolutionary.

Future wars would be won not by the side with the best soldiers, but by the side with the best logistics. Major Dwight D. Eisenhower, an instructor at the college in 1933, summarized this philosophy in Alukshire. The winner in modern war is the nation that can deliver more material to the battlefield faster than its enemy can destroy it.

This doctrine led to specific requirements formalized in the 1930s as the army began planning for potential future conflicts. In 1937, the War Department issued specifications for port construction capabilities that would seem absurd by European standards. American port construction units must be able to restore a completely destroyed harbor to basic operational status within 30 days.

They must operate independently without requiring local infrastructure. They must scale operations to match the size of the port being restored. The specifications created impossible demands. To restore a major port in 30 days required more equipment and personnel than most nations possessed for all military engineering operations combined. It required fabrication capabilities that could manufacture replacement components of any size in the field.

It required organizational structures that could coordinate thousands of workers across dozens of simultaneous operations without losing efficiency. The mathematics were brutally simple. Sherborg at full capacity could handle 20,000 tons of cargo per day. Every day the port remained closed cost the allies 20,000 tons of supplies.

Over 30 days, that totaled 600,000 tons, the equivalent of 2,000 Liberty ship cargos. The strategic value of reducing restoration time from 90 days to 30 days was therefore 1,200,000 tons of additional cargo delivered to the front lines.

To achieve this, the Americans made a design choice that European military doctrine considered wasteful. massive overinvestment in logistics infrastructure. While German engineering units were equipped to repair or construct facilities using local resources, American port construction companies carried everything they might need with them. The 156th Port Construction and Repair Group’s table of organization and equipment list read like the inventory of a major construction firm.

They possessed 47 bulldozers, 23 cranes rated from 5 to 40 tons, 31 dump trucks, 14 portable electrical generators capable of powering a small city, seven machine shops mounted on trucks that could fabricate steel components up to three tons, and 200 tons of assorted construction materials ranging from steel cable to concrete forms.

The entire unit’s equipment weight exceeded 4,000 tons. Critics within the army had questioned this approach throughout the 1930s. “We’re building construction companies, not military units,” one congressional testimony complained in 1938. “This level of equipment allocation is wasteful and represents poor planning.” But the army industrial college doctrine prevailed.

Backed by officers who understood that in industrial warfare there was no such thing as excess logistics capacity. The port construction and repair groups were deliberately overengineered. Carrying enough equipment to handle any conceivable demolition scenario. The organizational structure was equally revolutionary.

German port units operated under centralized command with strict hierarchical approval processes. A heritage of Prussian military tradition where initiative at lower levels was discouraged. American units operated under mission command doctrine. Commanders defined objectives allocated resources and allowed subordinate officers enormous latitude in execution. at Sherborg.

This meant that Lieutenant Commander Sullivan could propose lifting 90ton cranes without requesting permission up the chain of command. It meant that sector commanders could redirect equipment from other operations based on immediate needs. It meant that Navy CBS could fabricate custom lockgate components without waiting for engineering drawings to be approved in London.

The final element was resource prioritization. While German logistics prioritized combat units, ammunition and fuel went to divisions first, engineering second, American logistics gave port operations absolute priority during the critical restoration phase. Between June 27th and July 16th, 1944, every available transport vessel in the English Channel was directed to support Sherborg operations.

Combat units waited for supplies while port construction units received equipment within 24 hours of request. General Omar Bradley, commanding the US First Army, understood the trade-off. His divisions were fighting German forces with ammunition stocks running dangerously low. But he didn’t complain about the diversion of shipping to Sherborg. Every ton of equipment we send to Sibli’s engineers now, he told his staff on July 3rd, will return 10 tons per day once the port opens.

It’s the best investment we can make. This philosophy that logistics infrastructure was not support for combat operations, but rather the foundation that made combat operations possible, represented a fundamental reimagining of military priorities. The Germans had built an impressive system of destruction. The Americans had built an even more impressive system of construction.

The contest wasn’t about which side could blow things up more effectively. It was about which side could build things faster than the enemy could destroy them. In that contest, there was never any doubt about the outcome. The impact of Sherborg’s rapid restoration rippled outward with effects that changed the trajectory of the European campaign.

The immediate consequence was simple. The Allied armies in Normandy could continue advancing. But the strategic implications went far deeper. On July 20, 1944, the first week after the port’s initial opening, Sherborg handled 7,200 tons of cargo. This was modest by pre-war standards.

The port’s theoretical maximum was 20,000 tons per day, but it represented more tonnage than the Allies had moved across all of the Normandy beaches on D-Day itself. German planners had assumed zero tons per day from Sherborg through December. The difference between 0 and 7,200 tons daily meant that Allied divisions could maintain offensive operations rather than rationing ammunition.

By August 1, after comprehensive repairs to additional qua and births, Sherborg’s capacity reached 12,000 tons per day. By September 1, it peaked at 21,000 tons daily, exceeding its pre-war capacity. In a single month, Sherborg delivered more than 600,000 tons of supplies to Allied armies, exactly the amount German planners had assumed would be lost due to the port’s destruction.

The human cost of this achievement was remarkably light by wartime standards, though not without tragedy. Three divers died during salvage operations. Seaman First Class Robert McCarthy drowned on July 3 when his airline snagged on submerged debris. Petty Officer James Hughes was killed on July 8th by a delayed action mine that detonated while he was surveying a scuttled vessel.

and Corporal David Zang of the 156th died on July 11th when a crane cable snapped under tension, striking him in the chest. But these casualties stood in stark contrast to the losses that would have occurred had the port remained closed. Everyday Sherborg operated prevented supply shortages that would have forced Allied units to suspend offensive operations, giving German defenders time to establish stronger positions and inflict higher casualties on attacking American and British forces. The strategic math was calculated by Supreme Headquarters Allied Expeditionary Force in a

classified assessment dated August 15th, 1944. The early opening of Sherborg has directly enabled the continuation of Operation Cobra, the breakout from Normandy, and the subsequent pursuit across France. Conservative estimates suggest this has shortened the campaign by 30 to 45 days and prevented an estimated 15,000 25,000 Allied casualties that would have resulted from fighting through prepared German defensive positions.

German commanders recognized the disaster almost immediately. On July 18th, General Feld Marshall Gunter Funluga, commanding OB West, wrote to the German high command, “Enemy logistics capabilities have proven far superior to our intelligence estimates.

The rapid restoration of Sherborg has fundamentally altered the supply situation and enabled the enemy to maintain pressure across the entire front. Without corresponding port facilities available to our forces, the logistics balance heavily favors the enemy. Hitler’s reaction was characteristically delusional. On July 21, during a staff conference at the Wolf Slayer, he raged that the Sherborg demolitions had been inadequate and demanded that Henkeay be court marshaled for failing to destroy the port more thoroughly. Coolerheads prevailed.

Heneck retained his Knights Cross and his command, but the episode revealed Hitler’s fundamental misunderstanding of the situation. The demolitions hadn’t failed. American restoration had succeeded beyond any reasonable prediction. The consequences extended beyond immediate military operations. Sherborg became the template for every subsequent port operation in the European theater.

When Liavra fell on September 12, 1944, the Americans restored it to operation in 18 days using techniques refined at Sherborg. When Antworp’s port facilities were cleared of German demolitions in November 1944, the operation took 23 days, again using methods developed at Sherberg. The operation also validated pre-war American logistics doctrine in a way that influenced military planning for the next 80 years.

The after-action reports from Sherberg were studied at the Army Industrial College at West Point and at the Naval War College. They demonstrated conclusively that investment in logistics infrastructure, specifically the massive overengineering of port construction units, paid strategic dividends far exceeding their cost. A comparison with German logistics capabilities made the lesson explicit.

The German army’s entire engineer corps contained fewer specialized port construction troops than the Americans deployed to Sherberg alone. German floating crane capacity in all of Western Europe totaled less than the lifting capacity of the equipment the Americans brought to a single harbor. German field fabrication capabilities couldn’t match what American port units carried in their mobile machine shops.

This disparity wasn’t accidental. It reflected fundamentally different philosophies about the relationship between industrial capacity and military effectiveness. Germany built an army designed to win quick, decisive victories through operational brilliance and tactical superiority. Blitzkrieg. America built an army designed to win extended conflicts through logistical superiority and industrial overwhelming force.

Attrition warfare with machines rather than men. Sherborg proved which philosophy was correct in industrial age warfare. The same German efficiency that created such impressive demolitions ultimately meant nothing against an opponent who could rebuild faster than they could destroy. As one American engineering officer wrote in his journal on August 1, 1944, “The Krauts spent 3 months wrecking this port and thought they’d done something remarkable.

We fixed it in 3 weeks and barely broke a sweat. That about sums up why we’re going to win this war. By autumn 1944, as American and British armies raced across France toward Germany, Sherborg was handling more cargo than any port in the world. The ruins that von Schleban had boasted about were now the engine room of Allied victory.

The complete story of Sherberg’s restoration can be measured in numbers that reveal both the scale of destruction and the scale of American response. German demolitions at Cherburgg, June 1944. 27 vessels scuttled, ranging from 800 ton tugboats to the 11,000 ton floating dry dock. Two gantry cranes, 90 tons each, toppled into main channel. 43 smaller cranes destroyed or damaged beyond field repair.

17 major breaches in breakwater. Total 420 m of collapsed stonework. Eight lock gates destroyed, each weighing approximately 200 tons. 11 warehouses demolished. Total 47,000 square meters of covered storage. 504 individual demolition charges placed throughout port facilities. Estimated 800 tons of explosives expended on demolitions.

127 confirmed mines laid in channels and basins, 83 with anti-handling devices. American restoration operations, June 27 through September 1, 1944. Engineering personnel deployed 11,240 troops. Peak strength August 1944. Major units involved 1055th, 1056th, 1057th, 1060th Port Construction and Repair Groups, 357th Engineer General Service Regiment, Navy Construction Battalion 71 CBS, floating cranes deployed, 14 ranging from 50 to 200 tons lifting capacity vessels raised 27, 100% of scuttled ships, though Only 11 returned to service. Mines cleared, 127

confirmed, plus an estimated 40 additional uncharted devices. Lock gates restored. Eight six repaired in place. Two fabricated as field replacements. Qua restored to operation. 31 of 44 original births. New electrical infrastructure. 68 mi of power cable installed. New water lines. 23 mi of piping laid.

Casualty figures, three killed, 17 injured seriously enough to require evacuation. First cargo discharge, July 16, 1944. SS John J. Montgomery, 5,000 tons. Daily tonnage July 1631 average 4,200 tons. Daily tonnage August 131 average 12,700 tons. Daily tonnage September 130 average 21,400 tons. Total cargo discharged June 27 September 1 547,000 tons. Comparative timeline analysis.

German estimate for restoration 180 days 6 months. Allied pre-assault estimate 90 days. Actual time to first cargo discharge 20 days. Actual time to exceed pre-war capacity 67 days. Cost accounting. Estimated German investment in demolitions 8,000 man hours engineering time plus 800 tons high-grade explosives. American investment in restoration 2.

2 2 million man-hour, $47 million in 1944, equivalent to approximately $820 million in 2024. Return on investment. Every dollar spent on restoration yielded approximately $35 in delivered military cargo value through September 1945. One American officer’s assessment summed up these numbers succinctly. The Germans gave us their best punch. We barely felt it.

June 27th, 1945, exactly one year after Colonel Sibli’s first survey, Sherborg hosts a very different gathering. The war in Europe ended 6 weeks ago. The harbor is operating at peacetime capacity. Now, handling the reverse flow, American troops and equipment returning home.

General von Schlleban released from Allied captivity after Germany’s surrender returns to Sherborg as part of a historical documentation project. He stands on the same Kday France where Sibi stood 12 months earlier. The scene is unrecognizable. New cranes tower over expanded births. Fresh concrete repairs blend seamlessly with pre-war construction. Liberty ships and victory ships cue for births, loading rather than unloading now carrying the implements of war back to American arsenals.

An American logistics officer notices the former German general and approaches. Through an interpreter, von asks the question that has haunted him. How did you do it in 20 days? The American’s answer is characteristically direct. We brought more equipment to fix your port than you brought to destroy it. And we brought men who believed it could be done.

The final irony of Sherborg is this. The port that opened the Allied offensive in 1944 became the port that closed it in 1945. Through its docks passed 4.2 million tons of supplies during the 11 months it operated during the war.

more tonnage than Germany received through all of its Atlantic and North Sea ports combined during the same period. The harbor Germans destroyed to delay Allied victory became the harbor that guaranteed it. The lesson of Sherborg extends beyond engineering or logistics. It revealed a fundamental truth about industrial age warfare that the Germans never fully grasped.

In a contest between destruction and construction, construction always wins if one side possesses sufficient resources and will. The Germans had designed brilliant demolitions. The Americans had designed a system that assumed demolitions would happen and planned accordingly. Von Schlleben spent weeks planning Sherborg’s destruction. The Americans spent years building the capability to overcome it.

That disparity in preparation, more than any single battle or campaign decision, explains why Germany lost the war in the West. The examination of Sherborg’s ruins in June 1944 provided the proof. American victory wasn’t inevitable because Americans were better soldiers. It was inevitable because America had built a military machine that could overcome any obstacle through sheer industrial power.

That principle demonstrated dramatically at Sherborg defined the outcome of World War II and shaped military doctrine for the 80 years that followed. mode.

News

Iraqi Republican Guard Was Annihilated in 23 Minutes by the M1 Abrams’ Night Vision DT

February 26th, 1991, 400 p.m. local time. The Iraqi desert. The weather is not just bad. It is apocalyptic. A…

Inside Curtiss-Wright: How 180,000 Workers Built 142,000 Engines — Powered Every P-40 vs Japan DT

At 0612 a.m. on December 8th, 1941, William Mure stood in the center of Curtis Wright’s main production floor in…

The Weapon Japan Didn’t See Coming–America’s Floating Machine Shops Revived Carriers in Record Time DT

October 15th, 1944. A Japanese submarine commander raises his periscope through the crystal waters of Uli at what he sees…

The Kingdom at a Crossroads: Travis Kelce’s Emotional Exit Sparks Retirement Fears After Mahomes Injury Disaster DT

The atmosphere inside the Kansas City Chiefs’ locker room on the evening of December 14th wasn’t just quiet; it was…

Love Against All Odds: How Taylor Swift and Travis Kelce Are Prioritizing Their Relationship After a Record-Breaking and Exhausting Year DT

In the whirlwind world of global superstardom and professional athletics, few stories have captivated the public imagination quite like the…

Taylor Swift and Travis Kelce Swap the Spotlight for the Shop: Inside Their Surprising New Joint Business Venture in Kansas City DT

In the world of celebrity power couples, we often expect to see them on red carpets, at high-end restaurants, or…

End of content

No more pages to load