In August 1943, the Solomon Islands campaign was at its brutal peak and American Corsair pilots faced a harrowing reality. Their F4U Corsair’s advertised as the fastest fighters in the Pacific at 417 mph were routinely being outpaced by the Japanese Zeros during actual combat. On paper, the Corsair was supposed to dominate its 2000 horsepower Pratt and Whitney R280 double wasp engine, inverted gullwing design, and meticulously engineered airframe promised unrivaled performance.

and test pilots in Stratford, Connecticut, lauded it as a marvel of aeronautical engineering. But above the tangled jungles and harbors of New Georgia and Munda, where air combat was fought between 10,000 and 15,000 ft, pilots discovered a cruel truth. The lightweight, highly maneuverable Zeros could accelerate away from the Corsaires in level flight at precisely the moments when American pilots needed speed the most.

Major Robert Owens of VMF 215 documented the phenomenon after a disastrous engagement on August 7th over Reneova Harbor. 12 zeros against his squadron. Corsair’s diving from superior altitude, energy and tactics in their favor, yet unable to maintain pursuit when the Japanese fighters leveled off. Three Corsaires returned damaged.

One was lost, and Owens could only note bitterly, “We should have caught them.” The aircraft manual says, “We’re faster, but we’re not faster where it counts.” Squadron after squadron reported similar experiences, and American intelligence, upon examining captured Zeros, found no secret modifications. These underpowered, lightly armored Japanese fighters using only 1,130 horsepower were simply exploiting the physics of the denser air at combat altitudes, turning a theoretical advantage on paper into a deadly vulnerability for American pilots.

Between June and August 1943, Marine Corsair squadrons posted barely positive kill ratios. 1.3 enemy aircraft destroyed for every Corsair lost. A far cry from the dominance promised by the Navy, confidence among pilots eroded. Some even requesting transfers back to the slower but more predictable F4F Wildcats.

It was in this crisis that Staff Sergeant Jim Lefforts, a 31-year-old crew chief from Tut, Indiana, recognized the problem. a farm kid turned marine maintenance expert, lefforts had washed out of flight school due to depth perception issues, but had developed an uncanny ability to understand mechanical systems.

By 1943, he had logged 4,200 maintenance hours on radial engines, keeping Corsair’s flying when parts were scarce and logistics precarious. He noticed something subtle but critical. Returning Corsair’s at 15,000 ft were running cooler than expected, signaling that while the engine had power, it wasn’t being efficiently converted into thrust.

Through careful logging of air speed, engine RPM, and manifold pressure readings, lefforts discerned a clear pattern. At combat altitude, Corsair’s were losing 35 to 45 mph of potential speed, and the culprit was the propeller. Hamilton Standard’s three-bladed 13 ft 4-in propeller had been optimized for 25,000 ft, assuming future air battles would occur at high altitudes against European style bomber formations. Its 47.

5° blade pitch, perfect for thin air, was choking in the denser Pacific air at 10,000 to 15,000 ft. Like a car stuck in the wrong gear, unable to transfer engine power to forward motion. Regulations forbade field modifications, the propellers were government property, factory set to precise tolerances, and unauthorized changes could result in court marshall, dishonorable discharge, or even manslaughter charges if a modification caused a crash.

But Lefertz, having attended seven memorial services for pilots whose Corsaires were correct on paper but hopeless in reality, decided the risk was worth it. Over two nights, using a slide rule, Hamilton standard engineering specifications, and basic physics, he recalculated the optimal blade pitch for the dense combat air, determining that a reduction of just 2.

5° from 47.5° to 45° at the effective radius would allow the propeller to bite efficiently into the thicker air, converting engine power into thrust and recovering the lost 40 mph. per hour. Under the cover of darkness on August 12th, 1943, Leferts and two trusted mechanics, Corporal Eddie Brinks and Private First Class Tommy Hang, set to work on aircraft 17, assigned to First Lieutenant Bob Mccclure, a pilot who had narrowly survived multiple engagements where Zeros had simply outrun him.

They jacked the Corsair’s tail, removed the 130lb propeller, and carefully heated each blad’s route to 400° F, just enough to make the aluminum malleable, but avoid weakening its structure. Using a 30-foot pipe wrench, they twisted each blade with painstaking precision, monitoring displacement with a makeshift measuring jig and painstaking calculations until the three blades had been successfully repitched to 45°.

By 0 340 hours, aircraft 17’s propeller was complete, looking factory new, but aerodynamically transformed. The next morning, Major Greg Boington, unaware he was testing a modified propeller, taxied and took off for a routine patrol. At 15,000 ft, pushing the throttle to the firewall, the air speed needle climbed past expected limits, settling at 412 mph, an unprecedented gain of 40 mph.

Boington repeated the tests in shallow climbs, dives, and level flight, consistently verifying the improvement. Upon landing, he immediately sought out lefforts and demanded the modification be applied to every Corsair in the squadron. By August 18th, all 18 operational aircraft in VMF 214 had received the modification, and the combat results were immediate.

On August 19th, eight Corsaires intercepted 15 zeros escorting bombers. And in an engagement lasting just 11 minutes, VMF to Andadri Hetoat 14 claimed seven confirmed kills with no significant damage to their own aircraft. Pilots described the experience as revolutionary. For the first time, they could dictate engagement terms, deciding when to fight and when to disengage, leveraging the Corsair’s superior speed to exploit Zeros’s weaknesses rather than being constrained by physics.

The unauthorized modifications spread rapidly. Other squadrons intrigued and desperate to regain an edge visited Munda airfield to observe, learn, and replicate Leffort’s technique, often without formal permission. By September, kill ratios across modified Corsair squadrons had skyrocketed from 1.3 to 1 to over 11:1.

When the Navy Bureau of Aeronautics discovered the field modifications, a formal investigation was launched, threatening court marshal for lefforts, Boyington, and Major Bailey. The initial assessment labeled the changes as criminal negligence and reckless endangerment. But the combat data, pilot testimony, and independent engineering review told a different story.

The propellers were structurally sound. The modifications dramatically improved performance and the risks had been expertly managed. By October 1943, the Navy quietly acknowledged the specifications were wrong for combat altitude. And in November, formal technical orders were issued standardizing Leffort’s 45° pitch across all F4U1 and F4U1A Corsair’s retrofits proceeded immediately.

And by early 1944, thousands of Corsairs were combat optimized with improved thrust and speed, fundamentally changing air tactics in the Pacific. The modification allowed pilots to engage on their terms, extended their survivability, and directly contributed to the Corsair becoming the dominant carrier-based fighter in the theater, ultimately achieving kill ratios of 14 to1 by the end of the war.

Lefforts, who never received an official medal, continued his work training mechanics, and his innovation became a case study in adaptive field engineering, influencing procedures through Korea and beyond by bending propeller blades 2.5° at a time. Jim Lefforts didn’t just fix a plane. He reshaped the Pacific Air War, proving that the people closest to the problem can sometimes outenineer entire bureaus of experts and that innovation under pressure can change the course of history.

News

Inside Willow Run Night Shift: How 4,000 Black Workers Built B-24 Sections in Secret Hangar DT

At 11:47 p.m. on February 14th, 1943, the night shift bell rang across Willow Run. The sound cut through frozen…

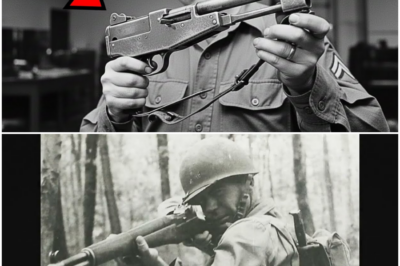

The $16 Gun America Never Took Seriously — Until It Outlived Them All DT

The $16 gun America never took seriously until it outlived them all. December 24th, 1944. Bastonia, Belgium. The frozen forest…

Inside Seneca Shipyards: How 6,700 Farmhands Built 157 LSTs in 18 Months — Carried Patton DT

At 0514 a.m. on April 22nd, 1942, the first shift arrived at a construction site that didn’t exist three months…

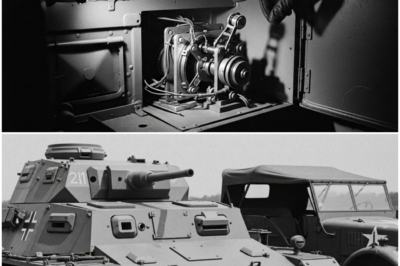

German Engineers Opened a Half-Track and Found America’s Secret DT

March 18th, 1944, near the shattered outskirts of Anzio, Italy, a German recovery unit dragged an intact American halftrack into…

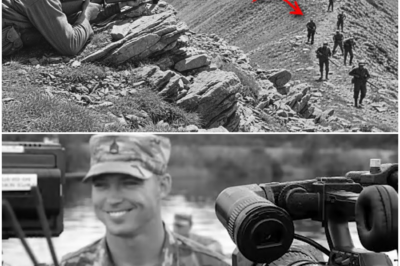

They Called the Angle Impossible — Until His Rifle Cleared 34 Italians From the Ridge DT

At 11:47 a.m. on October 23rd, 1942, Corporal Daniel Danny Kak pressed his cheek against the stock of his Springfield…

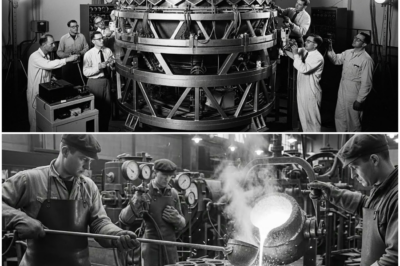

The Trinity Gadget’s Secret: How 32 Explosive Lenses Changed WWII DT

July 13th, 1945. Late evening, Macdonald Ranchhouse, New Mexico. George Kistakowski kneels on the wooden floor, his hands trembling, not…

End of content

No more pages to load