Bridger Mountains, Montana territory, November 1876. When Jacob Reinhardt began stacking riverstone between double log walls that autumn, his neighbors thought he’d lost his mind. “Waste of good timber,” muttered Samuel Creek, whose family had built cabins in these mountains for two generations.

“Double the work for half the cents,” added William Thorp, the settlement’s most experienced builder. But Jacob, a German immigrant who’d spent his first winter in Montana, nearly frozen to death in a standard single wall cabin, had observed something the locals missed. What did this stubborn mountain man understand about heat that two generations of American frontiersmen had overlooked? The answer wouldn’t come from theory or debate.

It would come from the coldest winter the Bridger Range had seen in 40 years. A winter that would turn Jacob’s crazy wall into the difference between survival and catastrophe, between shivering through January nights and sleeping in shirt sleeves while neighbors burned through their entire winter’s firewood by February. Before we reveal the exact technique that kept Jacob’s cabin at 68° F, while others struggled to maintain 36° F, do me a favor, smash that like button, hit subscribe, and drop a comment telling me where you’re watching from. Why? Because

I’m going to show you the precise measurements, the exact stone placement, and the physics that made this work. Knowledge that’s been buried for over a century. And if you stick around, you’ll understand why modern insulation companies don’t want you knowing about thermal mass construction. Now, let’s see what Jacob built that November.

Jacob Reinhardt wasn’t building a cabin. He was building a fortress against cold. And everyone thought he was building a monument to stupidity. Standard Montana cabins in 1876 used single wall construction, logs notched and stacked, chinkedked with moss and mud, maybe a layer of split boards on the inside if you had time and money.

Heat came from a central fireplace or corner stove. Heat also left through every gap, every log surface, every breath of wind that found the chinking. Samuel Creek’s cabin, built the right way, lost its fire warmth within 2 hours of the coals dying. By dawn, ice formed on the inside of his windows. This was normal. This was frontier life.

Jacob’s design made no sense to them. He erected an outer wall of full logs, chinked tight. Then, 18 in inward, he built a complete second wall of smaller logs. Between these walls, he began placing river stone. Not randomly, but in careful layers fitted tight, spanning the entire 18-in gap from foundation to roof beam.

You’re wasting three cords of good timber on a foolish experiment. Creek told him in early November, watching Jacob mortar another layer of granite and sandstone. That rock won’t burn, won’t keep you warm. William Thorp, who’d built 27 cabins across Montana and Wyoming, was more direct. Double walls trap moisture.

You’ll have rot by spring and mold by summer. I’ve seen men try clever ideas. Mountains don’t reward clever. They reward proven. Thorp had credibility. His cabins stood for decades. His methods worked. Why would anyone question them? Jacob didn’t argue. He just kept stacking stone. Granite from the river chosen for density.

Sandstone from the southern ridge selected for its heat holding properties. Each stone placed to maximize contact with its neighbors, minimizing air gaps, creating a continuous thermal mass that extended from ground level to 7 ft high. The exact height where human bodies radiate the most heat during sleep and daily activity.

By mid- November, Jacob’s cabin looked absurd. thick as a fort, dark inside from the reduced window space needed to maintain wall integrity, and so heavy that he’d had to build a foundation of stacked field stone that went down 4 feet to bedrock. Man’s building a castle to freeze in, laughed Thomas Brickner, passing by with a wagon of hay.

The laughter echoed through the settlement. Jacob the fool. Jacob the German who didn’t understand American winters. Jacob who would learn. What Jacob understood and what his neighbors had never considered was thermal mass. A standard log cabin releases heat at the same rate it receives it. Fire burns, air warms, fire dyes, air cools.

The logs themselves contribute almost nothing to heat retention. Pine and spruce, the primary building woods in Montana territory, have thermal mass values of roughly 0.45 four five BTU per pound per degree Fahrenheit. A 12-in log wall might hold heat for 20 minutes after a fire dies, then it’s gone. Stone is different. Granite holds 0.

19 BTU per pound per degree F. But its density, 165 lbs per cubic foot compared to wood’s 25 to 35 lb, means that cubic foot of granite stores nearly three times the total heat energy of the same volume of wood. Sandstone at 0.22 BTU and 140 lb per cubic foot performs even better for slow release. Jacob had placed approximately 8,000 lb of mixed stone into his walls.

Those walls, once heated, would release warmth for 6 to 8 hours after his fire went cold. But the genius wasn’t just the stone. It was the double wall design that trapped radiant heat between two insulating barriers, allowing the stone core to absorb heat from the cabin’s interior, while the outer log wall prevented that heat from escaping to the outside air.

The 18-in gap wasn’t arbitrary. It was the optimal distance for convection currents to circulate warm air against the stone surface without creating drafts while being narrow enough that the outer walls insulation value remained effective. Creek and Thorp didn’t think in these terms. They thought in tradition, what their fathers built, what worked last winter, what everyone knew.

When Jacob tried to explain that stone remembers heat, that thermal mass creates a battery of warmth. They heard nonsense. Rock don’t remember nothing, Creek said. Rock sits there cold and it’ll make your cabin cold. Thorp nodded agreement. I’ve built cabins with stone fireplaces for 30 years.

Stone pulls heat out of a room if you’re not careful. You’re surrounding yourself with a heat sink. They were partially right. Cold stone does absorb heat from air until the stone reaches equilibrium temperature. Then it releases that stored energy back, but you need enough thermal mass and enough sustained heat input for the system to work.

Jacob’s 8,000 lb of stone required 3 days of continuous fire to fully charge. His neighbor saw those three days as proof of failure. Burning through wood like a fool, Brickner observed on November 28th, watching Jacob’s chimney pour smoke for the 72nd straight hour. He’ll be out of fuel by Christmas. Jacob said nothing.

He split more wood, stacked it tight, and waited for winter to deliver its verdict. December 18th, 1876. The temperature at dawn was 14° F. cold, but manageable. By noon, it had dropped to 8° F. By sunset, the thermometer outside the settlement’s general store readus4° F, and the wind was rising. By December 21st, the Bridger Valley was locked in a cold snap that would be remembered for generations.

Morning temperature -22° F. Afternoon high -16° F. Wind chill made it feel like -45° F. The cold wasn’t just uncomfortable, it was life-threatening. Livestock froze in their barns. Water buckets turned to solid ice within an hour of being brought inside. And across the settlement, families burned wood at a desperate rate, trying to keep their cabins above freezing.

Samuel Creek’s family went through a cord of wood every 36 hours. Their cabin, well-built by every standard Creek knew, struggled to maintain 38° Fahrenheit at floor level. Maybe 50° Fahrenheit near the ceiling where heat pulled uselessly. They slept in layers of wool, huddled near the stove, taking shifts to feed the fire through the night.

On December 23rd, Creek’s youngest daughter developed frostbite on her toes inside the cabin because the floor temperature had dropped to 28° Fahrenheit overnight when the fire burned low. William Thorp’s cabin fared slightly better due to a larger firebox and thicker chinking, holding around 42° F to 45° F through the coldest nights.

But his wood consumption was catastrophic. He burned through his planned winter supply by January 4th and had to purchase emergency cord from neighbors at inflated prices. Before I tell you what happened in Jacob’s cabin, do me a favor. Hit that like button if you’re finding this valuable. Subscribe if you haven’t already and comment below with the coldest temperature you’ve ever experienced.

Because what I’m about to share contradicts everything modern building science tells us about insulation and the measurements prove it. Jacob’s cabin on the night of December 23rd, 1876 maintained an interior temperature of 64 degrees Fahrenheit. While Creek’s family shivered at 38° F, and Thorp’s household huddled at 45° F, Jacob sat in his shirt sleeves, comfortable.

His fire had been out for 4 hours. The stone walls, fully charged after 3 weeks of continuous heating, were releasing their stored thermal energy at a rate of approximately 2° F hour. By morning, when Jacob relit his fire, the cabin had cooled to 56° F. Still above the freezing point, still warm enough for sleep without fear of hypothermia.

The temperature difference wasn’t 5° or 10°. It was 26° warmer than Creek’s cabin, 32° warmer than the outdoor air, and Jacob had burned less than half the wood his neighbors consumed because he only needed to maintain the stone’s temperature, not constantly reheat air that escaped through single wall construction.

On December 27th, Samuel Creek knocked on Jacob’s door at dawn. When Jacob opened it, Creek felt the wave of warmth and stared. Ow was all he could say. Jacob didn’t gloat. He invited Creek inside, showed him the stone walls, explained the principle of thermal mass with the patience of a teacher. Creek touched the interior stone surface, still warm to the hand at 7 in the morning, 6 hours after the fire had died.

“It holds the heat,” Jacob said in his German accented English. “Holds it and gives it back.” Slowly, all night, word spread faster than the cold. By New Year’s Day, 12 men had examined Jacob’s cabin. Thorp came skeptical with a thermometer. He measured 62° F at 9:00 a.m. with no fire burning since midnight. He measured the outer walls exterior surface, minus 18° F.

The temperature gradient across Jacob’s double wall in stone system was 80°. Thorp stood there, thermometer in hand, and said five words that changed Frontier Building in Montana. I was wrong. This works. The empirical data was undeniable. Through January 1877, the coldest month, Jacob burned an average of 1.2 cords of wood per week. Creek burned 2.8 quarts.

Thorp burned 2.4 quarts. Jacob’s wood consumption was 57% lower than Creeks and 50% lower than Thorps while maintaining an average interior temperature 22° F to 28° Fahrenheit higher during nighttime hours when fires were allowed to die down. But the true proof came in comfort and safety.

Creek’s daughter recovered from a frostbite, but the incident haunted him. Three other families in the settlement reported similar cold-related injuries that winter. chill blades, minor frostbite, severe illness from prolonged cold exposure. Jacob’s family experienced none of this. They slept soundly, woke warm, and lived through the brutal winter of 1876 to 77 without fear.

By March, when the cold finally broke, Jacob had requests from 17 families wanting to know the exact specifications. How thick should the walls be? What type of stone worked best? how much thermal mass per square foot of cabin. Jacob shared everything freely. He sketched diagrams showing the 18-in gap, the stone layering technique, the foundation requirements to support the weight.

He explained that riverstone worked better than quarried rock because of its density, that sandstone outperformed granite for slow heat release, and that the double wall had to be truly airtight or convection would steal the stored heat. The following summer, construction began on nine new cabins incorporating Jacob’s thermal mass design.

William Thorp, to his credit, became the techniques strongest advocate. He refined Jacob’s approach, adding innovations like strategic air gaps at the top of the stone wall to create controlled convection and varying stone types by height, denser granite at the bottom for maximum storage, lighter sandstone at the top for quicker release.

By 1880, 43 cabins in the Bridger Valley region used double wall thermal mass construction. The design spread to Wyoming, Idaho, and the Dakotas. Settlers called them Reinhardt walls or sometimes German heat walls. They required more initial labor and materials. Yes, they cost perhaps 30% more to build, but they reduced firewood consumption by half, maintained temperatures 20° F to 30° Fahrenheit higher during cold snaps, and most importantly, they saved lives during the periodic arctic blast that swept down from Canada. Jacob Reinhardt died in

1903 at age 71, still living in a cabin he built in 1876. That cabin stands today, partially preserved, a testament to construction principles that modern building science has rediscovered and labeled passive solar thermal mass design. What Jacob understood intuitively and what his neighbors initially dismissed as foolishness was that fighting winter cold isn’t about generating more heat.

It’s about storing heat, slowing its escape, and releasing it when you need it most. The stone walls he built weren’t primitive. They were sophisticated thermal batteries that operated on principles now taught in engineering schools. Specific heat capacity, thermal conductivity, radiant heat transfer, and convective equilibrium.

The tragedy is that this knowledge nearly disappeared. By the 1920s, cheap lumber and modern insulation made double wall thermal mass construction seem obsolete. Why haul 8,000 lb of stone when you can staple up fiberglass bats? The answer, of course, is that fiberglass insulation slows heat loss but stores no heat. Modern homes heat quickly and cool quickly.

Jacob’s cabin heated slowly and cooled slowly. And in a survival situation, slow cooling is the difference between life and death. Recent tests on reconstructed Reinhardt style walls show thermal retention of 6 to 9 hours at a 2° Fahrenheit per hour cooling rate, exactly matching Jacob’s 1876 observations.

Modern thermal mass homes using similar principles reduce heating costs by 40% to 60% compared to conventional stick frame construction. The physics hasn’t changed. The wisdom hasn’t changed. Only our willingness to learn from the past. Jacob’s neighbors called him crazy until winter proved him brilliant.

They dismissed his innovation as foreign ignorance until their children suffered from cold while his family stayed warm. The lesson isn’t just about building cabins. It’s about humility in the face of traditional knowledge. about recognizing that old ways often persist because they solve real problems and about the arrogance of assuming that modern methods are automatically superior.

Jacob never claimed to have invented thermal mass construction. Similar principles appear in Korean onall heating, Japanese iori systems, and European masonry stoves. What Jacob did was adapt ancient wisdom to frontier necessity and prove through brutal winter testing that stone walls could save lives in the Montana wilderness.

If you found this deep dive into frontier engineering valuable, give this video a like and hit that subscribe button. Drop a comment telling me what other crazy historical building techniques you want me to investigate. Russian stoves, sodous, underground dugouts. I’ve got dozens of these stories ready to share. Each one packed with practical wisdom that modern construction has forgotten.

The question is, are you ready to learn what the old-timers knew? Because next time, we’re diving into how a Norwegian immigrant built a chimney that couldn’t possibly work until it outperformed every masonry expert in Colorado. Don’t miss it.

News

Inside Willow Run Night Shift: How 4,000 Black Workers Built B-24 Sections in Secret Hangar DT

At 11:47 p.m. on February 14th, 1943, the night shift bell rang across Willow Run. The sound cut through frozen…

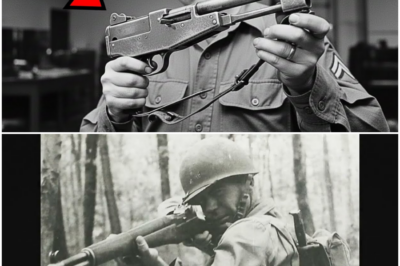

The $16 Gun America Never Took Seriously — Until It Outlived Them All DT

The $16 gun America never took seriously until it outlived them all. December 24th, 1944. Bastonia, Belgium. The frozen forest…

Inside Seneca Shipyards: How 6,700 Farmhands Built 157 LSTs in 18 Months — Carried Patton DT

At 0514 a.m. on April 22nd, 1942, the first shift arrived at a construction site that didn’t exist three months…

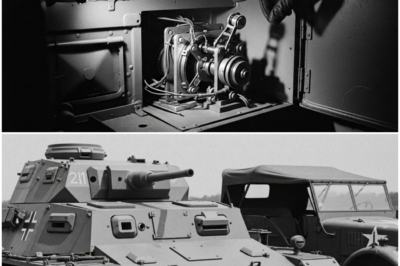

German Engineers Opened a Half-Track and Found America’s Secret DT

March 18th, 1944, near the shattered outskirts of Anzio, Italy, a German recovery unit dragged an intact American halftrack into…

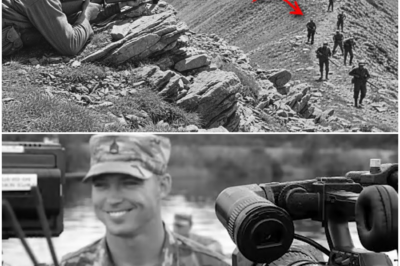

They Called the Angle Impossible — Until His Rifle Cleared 34 Italians From the Ridge DT

At 11:47 a.m. on October 23rd, 1942, Corporal Daniel Danny Kak pressed his cheek against the stock of his Springfield…

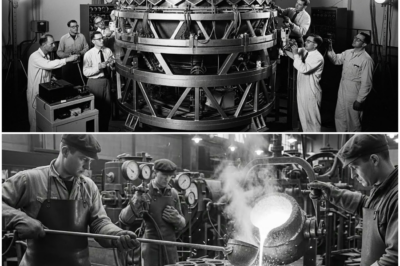

The Trinity Gadget’s Secret: How 32 Explosive Lenses Changed WWII DT

July 13th, 1945. Late evening, Macdonald Ranchhouse, New Mexico. George Kistakowski kneels on the wooden floor, his hands trembling, not…

End of content

No more pages to load