At 0514 a.m. on April 22nd, 1942, the first shift arrived at a construction site that didn’t exist three months earlier. Senica, Illinois, population 987. The men carried lunch pales and thermoses. Most had never seen an ocean. None had built a ship. By nightfall, they would begin constructing vessels designed to storm beaches under machine gun fire.

The impossible had a deadline, 18 months. The enemy had a head start of 3 years. If you’re interested in stories about ordinary people doing extraordinary things under impossible conditions, consider subscribing. We uncover the engineering and human drama behind World War II’s most overlooked achievements. The strategic problem was simple to describe, brutal to solve.

By spring 1942, the United States faced two oceans, three continents, and a logistics nightmare that would define the entire war. The German Yubot campaign had sunk over 2.4 million tons of Allied shipping in 6 months. Every convoy to Britain risked obliteration. Every supply line to North Africa stretched beyond sustainability.

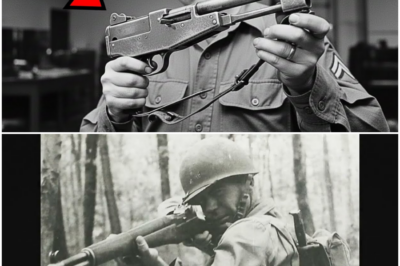

And the invasion of Europe, still years away, would require a vessel that didn’t exist in sufficient numbers. The landing ship tank, the LST, a flatbottomed, shallow draft ship capable of crossing oceans and beaching directly onto hostile shores. It needed to carry 30 tanks, 200 men, and enough fuel and ammunition to sustain them through the first 72 hours of combat.

Britain had 12. America had none. The War Department estimated they would need 300 minimum. They had 18 months to build them. The mathematics were unforgiving. Traditional shipyard production timelines measured construction in years, not months. A destroyer took 14 months from keel to commissioning. A Liberty ship built with revolutionary modular techniques still required 42 days.

An LST was larger than a Liberty ship, more complex than a destroyer, and the Navy wanted them faster than either. The initial estimates suggested 24 months per vessel. That timeline was unacceptable. By the time the first 100 ships were completed, the strategic window for invasion would have closed. The enemy would have fortified every beach from Norway to Greece.

The advantage of surprise would be lost. So the Navy cut the timeline in half, then cut it again. 12 months, then 8. The engineers protested. The welding sequences alone required 6 months to complete properly. Testing and sea trials added another three. But the protests were overruled. The deadline wasn’t negotiable.

It was set by enemy production rates, not engineering reality. Germany was building Yubot faster than the Allies could sink them. Japan was fortifying the Pacific faster than America could project force. Time wasn’t a resource. It was a weapon. And the only way to win was to build faster than physics should allow. The LST design itself was a compromise between competing impossibilities.

It had to cross the Atlantic, which meant it needed a seaorthy hull capable of handling 12 ft swells and 40 knot winds. But it also had to beach on hostile shores, which meant it needed a flat bottom that could run a ground without capsizing. Seaorthy hulls are deep drafted. Beaching vessels are shallow drafted.

The two requirements were mechanically contradictory. The solution was a hybrid design that satisfied neither requirement perfectly, but addressed both adequately. The bow was rounded for ocean travel. The stern was squared for stability during beaching. The keel was flat but reinforced with longitudinal stringers to prevent flexing under wave stress.

The result was a ship that wallowed in rough seas, rolled unpredictably in crosswinds and handled like a barge in anything above 10 knots. Crew members called it the large, slow target. But it worked. It carried tanks. It survived ocean crossings. It beed under fire. That was enough. Traditional shipyards couldn’t meet the demand.

East Coast facilities were already overwhelmed with destroyer and carrier production. West Coast yards focused on Liberty ships and troop transports. The Navy needed capacity that didn’t exist and workers who weren’t already building something else. So they looked inland to rivers, to farmland, to towns where men knew tractors, not turbines.

Senica, Illinois, sat on the Illinois River 80 mi southwest of Chicago. It had good rail access, flat land, and deep water during spring floods. That was enough. In January 1942, the Chicago Bridge and Iron Company received authorization to construct a shipyard on a cornfield. No blueprints, no precedent, just an urgent directive from Washington and the weight of history pressing down on frozen mud.

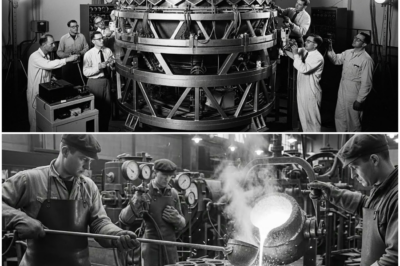

The first challenge wasn’t steel, it was space. An LST measured 328 ft long and 50 ft wide. To build 157 of them, the shipyard would need fabrication sheds, welding bays, cranes capable of lifting 90 ton bow sections, and launch ramps strong enough to slide 4,000 ton vessels into a river that wasn’t always deep enough to hold them. Construction began in February.

Workers poured foundations while snow covered the ground. By March, steel frames rose from the mud like skeletal cathedrals. By April, the first keel plates were laid. Speed wasn’t optional. It was the only variable they controlled. Germany wasn’t waiting. Japan wasn’t slowing down. And every day without an LST was another day the Allies couldn’t take a beach.

The workers came from everywhere. Farmers who’d lost land during the depression. miners from southern Illinois coal towns, welders from Chicago steel mills, women whose husbands were already overseas, high school boys who lied about their age. The draft had taken the youngest and strongest.

What remained were men over 35, teenagers, and women entering industrial work for the first time. None of it mattered. The shipyard didn’t care about resumes. It cared about showing up and learning fast. Training lasted three days. Welding instruction consisted of here’s the torch, here’s the seam, don’t burn through.

Rivet teams learned by watching then doing. Crane operators practiced on empty hooks until their hands stopped shaking. Mistakes were inevitable. Welds cracked, plates warped, rivets popped under stress. But the supervisors were patient in a way the calendar wasn’t. They taught the same lesson twice, three times, as many times as it took.

Because firing someone meant delaying a ship, and delaying a ship meant men died on a beach somewhere they’d never heard of. The rhythm of the work became muscle memory. Dayshift started with the 6:00 whistle. Workers clocked in, collected their tool assignments, and moved to their stations before the sun cleared the horizon. Welders checked their torches.

Riveters loaded pneumatic hammers. Crane operators tested cable tension and hydraulic pressure. By 6:15, the yard was alive with the sound of metal on metal, a constant percussion of hammers, saws, grinders, and the deep bass rumble of cranes moving overhead. The noise was overwhelming at first. New workers wore cotton in their ears, but it didn’t help much.

After a few weeks, the hearing loss became permanent. Most workers accepted it as the cost of employment. Deaf welders could still see the seam. Deaf riveters could still feel the hammer’s recoil. The work didn’t require hearing, only precision and endurance. The physical toll accumulated in layers. Welders developed chronic eye strain from arc flash.

Even with protective goggles, the ultraviolet light burned patterns into their retinas. Some went partially blind by age 40. Riveters suffered joint damage, elbows, shoulders, wrists from the constant vibration of pneumatic tools. Crane operators developed neck and back problems from 12-hour shifts spent looking up.

The medical station treated these injuries with aspirin, ice packs, and advice to take a day off. Few did. Missing a shift meant losing pay. Losing pay meant missing rent or falling behind on war bonds. So, they worked through the pain, modified their techniques to compensate, and developed private strategies for managing what the body couldn’t heal.

Some drank, some smoked, some found religion, others just endured. The work demanded endurance more than anything else. Not heroism, not brilliance, just the ability to show up in pain and do it again. By summer, the yard employed 6,700 workers across two shifts. The day crew started at 6:00 a.m. The night crew took over at 6:00 p.m.

12 hours on, 12 hours off, 7 days a week. Sundays were optional, but few took the option. The work was repetitive, exhausting, and maddeningly precise. Each LST required 3,400 tons of welded steel. Every joint had to be watertight. Every rivet had to seat flush. A single weak seam could flood a tank deck mid ocean.

A single misaligned plate could crack under wave stress and doom 200 men. The workers understood this. It wasn’t abstract. Their brothers, sons, and neighbors were crossing the Atlantic in ships someone else built. Now it was their turn. They carried that weight into every shift. They carried it home in their shoulders and hands. They carried it in silence because words couldn’t hold what the work demanded.

The construction method was modular, a technique borrowed from cargo ship production, but adapted for the LST’s unique design. Each vessel was divided into sections: bow, midship, stern, tank deck, and superructure. These sections were pre-fabricated in separate bays, then moved by rail-mounted cranes to the main assembly area.

Workers welded them together like puzzle pieces, each seam checked three times before final approval. The bow section was the most complex. It housed the massive hinged doors that would open directly onto enemy beaches. The doors had to be strong enough to withstand wave pressure during ocean crossings, yet light enough to operate manually under fire.

Engineers designed a hydraulic system, but it failed during testing. So, they simplified it. Chains and counterwes, muscle and leverage. It worked. That became the rule. Ifcomplexity failed, simplify until it didn’t. Each bow section weighed 90 tons and required six weeks to fabricate. The doors themselves were constructed from quarterinch steel plate reinforced with I-beam bracing.

They measured 30 ft wide and 15 ft tall, large enough to accommodate a Sherman tank with inches to spare on either side. The hinge mechanism was the critical failure point. Early designs used roller bearings, but salt water corroded them within weeks. The replacement design used bronze bushings packed with heavy grease. Simple, primitive, effective.

The doors opened on a 45° angle, creating a ramp that extended from the bow deck to the beach. When fully loaded, the ship’s draft brought the deck within 3 ft of the water line. The ramp bridged that gap. Tanks rolled off at 5 mph speeds, engines roaring, treads biting sand within seconds of leaving the deck.

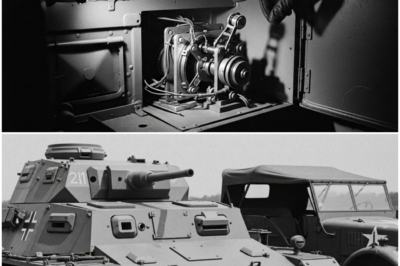

The process took 90 seconds per tank. Multiply that by 30 tanks, and the entire offload could be completed in 45 minutes if everything worked perfectly. It rarely did. The midship section contained the engine room, fuel tanks, and crew quarters. Two gray marine diesel engines, each generating 900 horsepower, drove twin screws at the stern.

The engines were reliable, but underpowered. A fully loaded LST could manage 11 knots in calm seas. In rough weather, that dropped to six or seven. The fuel capacity was 160,000 gallons, enough for a transatlantic crossing with minimal reserve. Navigation required constant attention. The flat bottom design made steering unpredictable. Crosswinds pushed the bow off course.

Following seas lifted the stern and reduced propeller bite. Beam seas caused rolling that could exceed 30°. Experienced crews learned to anticipate these behaviors. New crews didn’t. Several LSTs capsized during shakedown cruises. Others ran a ground in harbors. The Navy accepted these losses as training expenses.

Better to lose a ship in friendly waters than under fire. The tank deck ran the length of the ship, an open steel corridor wide enough for two Sherman tanks side by side. No internal bulkheads, no compartmentalization. If the hull breached, the entire deck would flood in minutes. The Navy knew this. The crews would know this. But speed and capacity mattered more than safety margins.

An LST wasn’t designed to survive a torpedo hit. It was designed to deliver armor to a beach, offload under fire, and leave before the enemy adjusted range. Survivability was secondary to function. That logic haunted the workers. They built these ships knowing their flaws, knowing the compromises, knowing that somewhere on some beach those compromises might kill the men inside.

But they also knew the alternative. Without LSTs, there would be no invasion. Without an invasion, the war would drag on for years. So they kept welding, kept riveting, kept building ships that had to be good enough because perfect wasn’t possible in 18 months. The welding process consumed most of the construction timeline.

Each LST required over 47,000 linear feet of welded seams, nearly 9 m of continuous metal fusion. The welds had to be watertight, structurally sound, and capable of flexing under stress without cracking. Achieving this required precise heat control, consistent rod speed, and clean base metal. Any contamination, rust, oil, moisture would weaken the weld.

Quality control inspectors used X-ray equipment to check critical seams, but most welds were verified visually. A good weld showed consistent ripples, minimal spatter, and no visible gaps. A bad weld looked rough, uneven, or porous. Inspectors marked bad welds with chalk. Welders ground them out and redid them. No arguments, no shortcuts.

The ship wouldn’t float if the welds didn’t hold. And if the ship didn’t float, nothing else mattered. The launch process was unlike any other shipyard in America. Traditional yards used dry docks or slipways that extended directly into deep water. Senica didn’t have that luxury.

The Illinois River was shallow, only 9 ft deep during low water. An LST drew 4 ft when empty, 14 ft when loaded. That meant launches had to be timed with spring floods when the river temporarily swelled to 18 ft. Missed the window and the ship sat stranded on the bank until the next flood cycle. The solution was brutal and effective.

Greased wooden skids. Each LST sat on a cradle of timber rails coated with thick layers of soap and tallow. Workers removed the support beams holding the ship in place. Gravity did the rest. The vessel slid down the ramp, gained speed, and hit the water with enough momentum to carry it into the river’s center channel.

The impact was violent. Steel groaned. Welds screamed. Water surged over the bow deck. Sometimes the ship rocked so hard it nearly capsized. But it floated. Every time it floated, and every time the workers on the bank watched in silence, waiting to see if their work would hold. It always did. Not because the ships were perfect, butbecause the men who built them understood that good enough on time saved more lives than perfect, too late.

By the end of 1942, Senica had launched its first 12 LSTs. By mid 1943, the yard was producing eight ships per month. The pace was relentless. Sections moved from fabrication to assembly in 48 hours. Welding crews worked in rotating teams, never stopping, never slowing. Quality inspectors walked the decks with chalk and hammers, marking flaws that had to be fixed before the ship could leave.

Some defects were structural, cracked welds, misaligned frames, weakened rivets. Others were minor, paint inconsistencies, loose fittings, cosmetic issues that wouldn’t affect seaorthiness. The inspectors ignored the minor problems. There wasn’t time. If it floated, if it held tanks, if the engines turned and the doors opened, it passed. That was the standard.

Not ideal, not safe by peacetime metrics, but faster than the enemy, and that was the only metric that mattered. The human cost of this speed was measured in injuries, not deaths, but the injuries were constant. Welders suffered flash burns from ark light, temporary blindness that lasted hours, sometimes days.

Rivet crews lost fingers in pneumatic hammers. Crane operators misjudged loads and dropped steel plates that crushed feet, shattered knees, bent spines. The shipyard had a medical station staffed by two nurses and a retired doctor. They treated an average of 30 injuries per week. Most were minor cuts, bruises, sprains. Some were not. Three men died during construction.

One fell from scaffolding. One was crushed between a crane and a steel plate. One drowned when a section slipped during a river test and pinned him underwater. Their names were added to a memorial plaque near the main gate. Work continued the next day. The war didn’t pause for grief. Neither did the shipyard.

The workers developed rituals to manage the weight. Every completed LST was christened with a bottle of champagne, usually donated by local businesses or workers families. The bottle was smashed against the bow just before launch. If it didn’t break on the first swing, it was considered bad luck. Superstition maybe.

But in a job defined by uncertainty, small rituals provided structure, control over the uncontrollable. After each launch, the dayshift gathered near the river to watch the ship float down river toward the Mississippi. They didn’t cheer, didn’t celebrate, just watched, acknowledged, then returned to the next hull waiting in the assembly bay.

There were always more, always another keel to lay, another bow to weld, another ship that had to be finished before someone needed it on a beach they’d never see. Winter in Illinois tested the shipyard in ways combach never would. Temperatures dropped below zero. Ice formed on the river in sheets thick enough to walk on. The cranes froze.

Welding torches wouldn’t light. Steel became brittle, prone to cracking under stress. Workers wore three layers of clothing, gloves so thick they could barely grip tools and wool caps that didn’t stop the cold from penetrating. The work didn’t stop couldn’t stop. The Navy didn’t issue weather exemptions, so the shipyard adapted.

Diesel heaters were positioned near welding stations. Canvas tarps were draped over work areas to trap heat. Night shifts became more dangerous. Visibility dropped. Footing became treacherous on ice sllicked decks and exhaustion compounded every risk. Accidents increased. A welder slipped on frozen scaffolding and fell 20 ft.

He survived but never returned to work. A crane operator lost three fingers to frostbite after his gloves tore during an overnight shift. The medical station ran out of bandages, aspirin, and sympathy. The workers kept coming, kept working, because the alternative, going home, admitting defeat, letting the schedule slip, felt worse than the cold.

The war wouldn’t wait for spring. Neither would they. The river itself became an adversary. During spring floods, the water rose fast, sometimes 3 ft in 24 hours. Launch schedules had to be accelerated or delayed based on water level predictions that were often wrong. Too low and the ship grounded before reaching the main channel.

Too high and the launch ramp was submerged, making the cradle release unpredictable. Engineers monitored river gauges every 6 hours. When the water level hit 16 ft, the launch window opened. They had 48 hours before the flood peaked and began receding. During those 48 hours, the shipyard launched as many vessels as possible, sometimes three or four in a single day.

The process was chaotic. Crews worked in rotating shifts to prepare each ship. Cradles were greased. Support beams were cut. Chains were attached to slow the descent if the ship slid too fast. And then gravity took over. The ship moved slowly at first, then faster, then impossibly fast, hitting the water with a sound like thunder. Spray erupted.

The hull rocked. Workers on the bank heldtheir breath until the ship stabilized. Then they moved to the next one. There was always a next one. Women made up nearly 30% of the workforce by 1943. They welded, riveted, operated cranes, inspected hulls, and managed supply logistics. The work didn’t differentiate by gender, only by competence.

A weak weld was a weak weld regardless of who made it. A missed rivet was a missed rivet. The supervisors judged results, not assumptions. That didn’t eliminate prejudice, but it reduced it to irrelevance. The ships didn’t care who built them. Neither did the men who would sail them into combat. So the women worked the same shifts, carried the same tools, and bore the same scars.

Some had husbands overseas. Some had sons in uniform. Others had no personal connection to the war beyond the radio broadcasts and ration books. It didn’t matter. They showed up. They learned. They built. And when the war ended, many of them would be dismissed, sent home, told their labor was temporary.

But the ships they built weren’t temporary. Those ships crossed the Atlantic, stormed Normandy, landed at Sicily, and carried tanks into Germany. The women who built them knew this, remembered this, carried it. The supply chain that fed Senica was a logistical marvel in itself. Every LST required 3,400 tons of steel plate delivered by rail from mills in Pittsburgh and Gary.

The steel arrived in standardized sheets/4 in/ in and 3/4 in thickness cut to rough dimensions but requiring final shaping on site. Each shipment took 4 days to arrive and had to be offloaded, sorted, and stored before the next shipment came in. Delays were constant. Rail cars were diverted to higher priority destinations.

Steel mills struggled to meet demand for both ship building and tank production. Quality control issues occasionally resulted in entire batches being rejected, rust contamination, incorrect alloy composition, or dimensional variances that couldn’t be corrected. When shipments were delayed, the yard couldn’t stop. Workers improvised.

They scavenged steel from completed sections to patch incomplete ones. They reworked rejected plates by grinding off surface rust and recutting to size. They learned to work around shortages the way soldiers learned to work around supply failures by adapting, improvising, and accepting that perfection was a luxury they couldn’t afford.

Beyond steel, the ships required hundreds of other components. Diesel engines, propeller shafts, pumps, valves, electrical wiring, navigation equipment, life rafts, fire suppression systems, and anti-aircraft guns. Each component came from a different supplier. Each had its own lead time. Each could delay the entire ship if it arrived late or defective.

The logistics office tracked thousands of parts across dozens of suppliers using nothing more sophisticated than typewriters, filing cabinets, and telephone calls. The system worked because the people running it understood urgency. When a part was delayed, they called every day until it shipped. When a part arrived damaged, they requisitioned a replacement and juryrigged a temporary solution.

When suppliers couldn’t meet demand, they found alternate sources, sometimes purchasing civilian equipment and modifying it for military use. The bureaucracy was minimal, the decision-making was fast, and the mistakes, inevitable, frequent, costly, were corrected in real time without blame or delay.

The goal wasn’t perfection. It was completion. and completion required flexibility that no manual could teach. In early 1944, the Navy issued new specifications. The LST design was modified to include additional anti-aircraft guns, reinforced deck plating, and improved engine ventilation. Senica adapted within 2 weeks.

Engineers retrained workers. Assembly sequences were revised. Supply chains shifted to accommodate new materials. The modifications added 3 days to the construction timeline. The yard absorbed the delay by extending shifts and eliminating non-essential inspections. By March, the new LSTs rolled out on schedule.

The modifications were good ones. They saved lives, but they also revealed a hard truth. Perfection was iterative and iteration required time the war wouldn’t give. So the ships left imperfect, carrying improvements that would be tested in combat, refined in blood, and incorporated into the next hall. That was the cycle. Build, test, fail, adapt, repeat. It wasn’t elegant.

It wasn’t safe, but it was faster than the enemy’s ability to stop it. The strategic impact of Senica’s production became clear in the summer of 1944. Operation Overlord, the Allied invasion of Normandy, required 236 LSTs. Senica provided 43 of them. On June 6th, those ships crossed the English Channel, beed on Omaha, Utah, Gold, Juno, and Sword, and offloaded the armor that would break through German defenses.

The ships took casualties. Mines tore open holes. Artillery fire shattered super structures. Aircraft strafed exposed decks. 14 LSTs were lost in the first 72hours. But the rest kept running, kept beaching, kept delivering tanks, trucks, fuel, and ammunition until the beach head was secure. The men who built those ships in Senica never saw the invasion.

They listened on radios, read reports in newspapers, wondered if their ship was one of the ones that made it or one of the ones that didn’t. They never knew. The Navy didn’t track individual holes that way. But it didn’t matter. Every ship they built was someone’s ship. Every tank delivered was someone’s chance to survive the first hour.

That was enough. The performance of LSTs under combat conditions revealed both their strengths and their fatal vulnerabilities. The shallow draft that allowed beach landings also made them susceptible to mines. German forces had seated the approaches to Normandy with contact mines, pressure mines, and magnetic mines designed to detonate beneath ship’s keels.

LSTs with their flat bottoms triggered these mines more frequently than deeper drafted vessels. When a mine detonated beneath an LST’s tank deck, the explosion had nowhere to dissipate. The blast ripped through the hull, flooding the entire deck within minutes. Crews had almost no time to evacuate. Some ships sank in under 5 minutes.

Survivors described the sound not a loud explosion, but a dull thump followed by the groan of steel buckling. Then water, cold, fast, unstoppable. The tank deck became a trap. Tanks broke loose from their chains and shifted as the ship listed. Men were crushed. Others drowned in compartments that flooded before they could reach the exits.

The official casualty reports listed numbers. 14 ships lost, 387 men killed. But behind those numbers were welders from Senica who’d spent six weeks perfecting the seams on a bow section that split apart in 30 seconds. Riveters who’d inspected every plate on a hole that settled to the bottom of the English Channel with its cargo still chained to the deck.

Artillery fire posed a different kind of threat. LSTs carried minimal armor, just enough to protect the engine room and bridge from small arms fire. Anything larger punched through. German 88 mm guns positioned on coastal bluffs could penetrate an LST’s hull at ranges exceeding 2,000 yards. The ships had no defense against this.

Their top speed of 11 knots meant they couldn’t maneuver effectively. Their anti-aircraft guns were useful against low-flying aircraft, but couldn’t elevate high enough to target cliff-mounted artillery. So, the LSTs relied on smoke screens, naval gunfire support, and speed, what little they had to survive the run to the beach.

Some made it, others didn’t. The ones that didn’t became burning wrecks, beached and abandoned, their holes smoldering for days after the battle moved inland. Reconnaissance teams later cataloged the damage. Holes the size of barrels punched through the superructure. Entire sections of deck peeled back like tin cans and bodies still inside, charred beyond identification.

Those reports made it back to the War Department. They didn’t make it back to Senakica. The workers never knew how many of their ships survived. They only knew how many they’d built. 157. And they hoped that was enough. By August 1944, General George Patton’s third army was racing across France faster than supply lines could sustain.

His tanks outran their fuel. His infantry outran their ammunition. Logistics became the limiting factor. Not German resistance, but the inability to deliver enough material fast enough to maintain momentum. The solution was the same as it had always been, LSTs. They fied supplies across the channel, up French rivers, and directly onto improvised docks near the front lines.

Patton’s tanks carried Senica steel. His supply convoys rolled off Senica ramps. The farm hands who built those ships made his advance possible. Not through heroism, not through sacrifice, through competence, speed, and the willingness to show up every day and build something that had to work because failure wasn’t survivable.

Patton’s advance toward the Rine was constrained by a problem no tactical brilliance could solve. fuel. His armor divisions consumed 400,000 gallons per day. Resupply convoys traveling overland from Normandy took 4 days to reach the front, assuming the roads weren’t clogged with refugees, damaged by air strikes, or interdicted by German counterattacks.

The Red Ball Express, a dedicated truck convoy system, helped but couldn’t keep pace with Patton’s speed. By September, his tanks were idling with empty fuel cells while supply depots in Normandy held millions of gallons that couldn’t be delivered fast enough. The LST provided a solution.

Instead of trucking fuel across hundreds of miles of contested territory, LSTs loaded fuel drums directly at English ports crossed the channel and sailed up the sane river to within 20 m of Patton’s forward positions. The fuel was offloaded onto smaller barges, then trucked the final distance. The entire process took 36hours instead of 4 days.

That 36-hour advantage allowed Patton to resume his advance in late September, pushing toward the German border, while other Allied armies remained stalled due to supply shortages. The Ryan crossing in March 1945 represented the culmination of LST utility in the European theater. Patton’s plan required crossing a river 1,200 ft wide under fire with enough armor and infantry to establish a bridge head before German forces could organize a counterattack.

Conventional bridging equipment was too slow. Pontoon bridges took hours to assemble and were vulnerable to artillery fire. The LST offered an alternative, mobile bridging. Engineers modified several LSTs by welding additional ramps to the bow, effectively creating floating bridges that could position themselves against the riverbank and offload vehicles directly onto the opposite shore.

The modification took 3 days. The Rine crossing took less than 12 hours. Patton’s tanks rolled off LSTs onto German soil while engineers were still assembling permanent bridges downstream. The speed of the crossing prevented German forces from establishing effective defensive positions. By the time they reacted, American armor was already 10 mi inland.

The LSTs that made this possible were built by farm hands in Senica, who’d never seen the Rine, who didn’t know Patton, who had no understanding of grand strategy or operational tempo. They just built ships, and those ships became bridges. and those bridges became victories. The final LST rolled off Senica’s assembly line in November 1945, 5 months after Germany surrendered, 3 months after Japan.

The war was over, but the shipyard kept building until the contract was fulfilled. 157 ships delivered on time. The workers were laid off in waves. The first cuts came in September. The final shift ended on November 30th. They cleaned their tools, turned in their badges, and walked out through gates that would be padlocked by December.

Some returned to farms. Some moved to Chicago for factory work. Some stayed in Senica, working jobs that felt smaller after what they’d done. The shipyard itself was dismantled. Cranes were sold for scrap. Fabrication sheds were torn down. The launch ramps were left to erode into the riverbank. Within two years, almost nothing remained.

No historical marker, no museum, just fields returning to corn and soybeans. The community of Senica transformed during those 18 months in ways that couldn’t be easily reversed. The population swelled from under a thousand to over 7,000 when you included workers who commuted from surrounding towns. Housing couldn’t keep up.

Workers slept in shifts. Boarding houses rented beds by the hour with one man sleeping while another worked. Temporary barracks were constructed near the shipyard, housing 200 workers in wooden structures that leaked during storms and froze during winter. The town’s single grocery store ran out of supplies by Tuesday every week.

Rationing was supposed to distribute food equitably, but the shipyard workers needed more calories than ration books allowed. Black markets emerged. Farmers sold directly to workers, bypassing official channels. The local sheriff ignored these transactions. Everyone understood the situation. The workers were building the ships that would end the war.

If they needed extra butter or eggs to do it, the law could look the other way. The social fabric strained under the pressure. Established families resented the influx of outsiders. Longtime residents complained about noise, traffic, and the loss of small town tranquility. Bar fights increased. The single doctor medical practice became overwhelmed.

The two- room schoolhouse had to expand to accommodate children whose families had relocated for shipyard work. Not everyone adapted well. Some workers quit after a few weeks, unable to handle the physical demands or the social isolation of a town that didn’t want them. Others stayed but withdrew, working their shifts, returning to boarding houses, speaking to no one.

The psychological toll of the work went unagnowledged. There was no language for it yet. No concept of industrial fatigue or repetitive stress trauma. Workers who broke down were simply labeled as weak and replaced. Those who endured did so by developing private coping mechanisms. Drinking, religion, denial. The work demanded everything.

The community had nothing left to give. So people learned to live in parallel, existing in the same space but occupying different realities. The workers built ships. The town’s people endured the disruption. And when the war ended, both groups wanted the same thing, for everything to go back to the way it was.

It never did. The LSTs built at Senica served in every major amphibious operation of World War II. Normandy, southern France, Sicily, Anzio, Ewima, Okinawa. They carried British tanks into Burma, Australian troops into New Guinea, Soviet forces into occupied Europe under land lease agreements.Some were converted into hospital ships.

Others became repair vessels. A few were sold to Allied navies after the war and served into the 1970s. The last Senica built LST was decommissioned in 1974, 30 years after it slid into the Illinois River on greased wooden skids. By then, the workers who built it were in their 60s and 70s. Some had died.

Most had forgotten the hull numbers and launch dates. But they remembered the weight of the work, the injuries, the exhaustion, the pride. Not the loud performative pride of parades and medals, but the quiet pride of knowing they’d done something that mattered when it mattered most.

If stories like this resonate with you, stories about the invisible people who shaped history, consider subscribing. We bring these forgotten moments back into focus, one documentary at a time. The Senica shipyard’s legacy isn’t written in stone. It’s written in steel, scattered across ocean floors, rusting and shipbreaking yards, and preserved in a handful of maritime museums.

The workers left no monuments, no memorials, no grand speeches about duty and sacrifice. They built ships because the country needed ships. They worked because the work was there. And when the work ended, they went home. That’s the story. Not dramatic, not cinematic in the Hollywood sense, but true in a way that Hollywood rarely captures.

Ordinary people, impossibly short timelines, and results that changed the course of a war. 6,700 farm hands, welders, riveters, and crane operators, 157 ships, 18 months, and a general who crossed the Rine on steel they’d never seen, carrying tanks they’d never touched into a victory they helped build but would never claim.

The Illinois River still flows past Senica. The fields still grow corn. And somewhere in a military archive or a veteran’s attic, there’s a photograph of a ship sliding into the water. Workers watching from the bank, wondering if their work would hold. It did every time. Not because it was perfect, but because it was finished.

And in war, finished always beats perfect. Always.

News

Inside Willow Run Night Shift: How 4,000 Black Workers Built B-24 Sections in Secret Hangar DT

At 11:47 p.m. on February 14th, 1943, the night shift bell rang across Willow Run. The sound cut through frozen…

The $16 Gun America Never Took Seriously — Until It Outlived Them All DT

The $16 gun America never took seriously until it outlived them all. December 24th, 1944. Bastonia, Belgium. The frozen forest…

German Engineers Opened a Half-Track and Found America’s Secret DT

March 18th, 1944, near the shattered outskirts of Anzio, Italy, a German recovery unit dragged an intact American halftrack into…

They Called the Angle Impossible — Until His Rifle Cleared 34 Italians From the Ridge DT

At 11:47 a.m. on October 23rd, 1942, Corporal Daniel Danny Kak pressed his cheek against the stock of his Springfield…

The Trinity Gadget’s Secret: How 32 Explosive Lenses Changed WWII DT

July 13th, 1945. Late evening, Macdonald Ranchhouse, New Mexico. George Kistakowski kneels on the wooden floor, his hands trembling, not…

America Lost Malaysian Tin in 1942 — So Engineers Reinvented The Soup Can DT

February 15th, 1942. Singapore. When British Lieutenant General Arthur Persal surrendered Singapore to Japanese forces, 85,000 Allied troops became prisoners…

End of content

No more pages to load