At 11:47 p.m. on February 14th, 1943, the night shift bell rang across Willow Run. The sound cut through frozen Michigan air, sharp and metallic, echoing off aluminum walls and concrete floors. 4,000 workers moved through the darkness toward Hangar 7. Their footsteps crunched on gravel paths dusted with snow.

Their breath formed clouds in the sub-zero cold. Most of them were black. Nearly all of them were invisible to history. They walked past the main assembly lines where daylight photographers captured white workers riveting B24 fuselages for news reels and propaganda films. Flashbulbs illuminated those scenes. Reporters took notes.

Life magazine sent writers to document American industry at war. But Hangar 7 existed in a different world. No cameras, no reporters, no official records of who built what inside those walls. The workers passed through a side entrance marked only with a number. No sign identified the building’s purpose. The hangar doors closed at midnight.

What happened next would help win the war, but America wasn’t ready to admit who made it possible. If you’re interested in untold stories from World War II, stories about the people who built victory in silence, consider subscribing. This channel exists to remember what others chose to forget.

Willow Run was supposed to be Henry Ford’s masterpiece, a mileong assembly line designed to mass-produce B24 Liberator bombers faster than any factory in history. The building itself was unprecedented. 67 acres under one roof, 3 million square ft of production space. Ford promised the government one bomber every hour.

That meant 24 aircraft per day, 720 per month. The promise was made in 1941 when America wasn’t even at war yet. By early 1943, with American forces fighting on two fronts, Ford wasn’t even close to delivering. The main assembly line produced 12 aircraft per day when they needed 30. Fuselage sections arrived late from subcontractors. Wing assemblies didn’t fit because measurements were off by fractions of an inch.

Riveting teams fell behind schedule every single shift. Quality control rejected one in five completed sections. The bottleneck wasn’t the machines. The equipment was state-of-the-art. Hydraulic presses capable of shaping aluminum sheets into curves precise enough to cut through air at 290 mph. Pneumatic riveters that could drive 5/8 in rivets through double layered aluminum in under 2 seconds.

overhead conveyor systems that moved 15,000 lb fuselage sections with the precision of a watch maker. The machinery worked perfectly. The problem was human. The bottleneck wasn’t the machines. It was the mathematics of prejudice. In 1942, the United States military needed bombers faster than Detroit could build cars.

But Detroit’s workforce had a problem. White workers refused to train black workers. Union locals blocked black employees from skilled positions. Factory managers assigned black laborers to janitorial duties, loading docks, and material transport, never to the assembly line itself. This wasn’t inefficiency, it was policy.

The UAW’s local 50 at Willow Run had negotiated contracts that explicitly restricted where black workers could be placed. Ford’s management, desperate to avoid strikes, complied. But by February 1943, the numbers no longer allowed for compliance. The Army Air Forces needed 2,000 B-24s immediately.

Ford was contractually obligated to deliver. The daylight crews couldn’t meet the quota. Someone at Ford’s production office realized they had a workforce they weren’t using. 4,000 black workers, employed but underutilized, trained but restricted. The solution was as simple as it was cowardly. Put them on the night shift in a separate hanger where no one would see.

Hangar 7 sat on the northern edge of Willow Run, isolated from the main production floor. It had been used for experimental modifications and repair work. In February 1943, it became something else, a shadow factory. The official work orders listed it as auxiliary fuselage assembly. The real purpose was to solve Ford’s production crisis without triggering a white worker strike. The plan was efficient.

The morality was absent. The 4,000 workers assigned to Hangar 7 weren’t volunteers. They were reassigned without warning. Most had been working day shifts in material handling or facility maintenance. On February 10th, 1943, they received new shift assignments. midnight to 8:00 a.m. No explanation, no additional pay.

The work was different, though. For the first time, black workers at Willow Run would be building airplanes, not cleaning up after the people who did. Inside hangar 7, the layout mirrored the main assembly line, but compressed. Fuselage sections moved on overhead trolleys suspended from steel I-beams 40 feet above the floor.

The trolleys ran on tracks, moving sections from station to station with mechanical precision. Each section weighed 3,000 lb. The aluminum skin was 0040 in thick, thinner than a dime. Strong enough to withstandcombat damage at altitudes where the temperature dropped to 40 below zero. Riveting stations lined both sides of the assembly path.

Each station had two work platforms, one inside the fuselage, one outside. The inside worker held the bucking bar. The outside worker operated the pneumatic hammer. They worked in darkness most of the time. The fuselage interior had no lighting until final assembly. The workers used handheld lamps that cast shadows across aluminum ribs and stringers.

The metal reflected light in strange patterns. It felt like working inside a rib cage made of steel. Hydraulic presses shaped aluminum into bulkheads. The presses operated at 2,000 lb of pressure per square inch. The sound they made when forming metal was deep and resonant, like thunder contained in a box. The operators learned to read the sound.

A clean press sounded smooth. A metal flaw produced a crack in the tone. Experienced press operators could identify a stress fracture before the metal failed. The workspace was functional, not comfortable. Lighting was dimmer than the main floor. The ceiling fixtures were spaced farther apart to save on electricity costs.

Workers brought their own supplemental lights. Mechanics lamps with spring-loaded clips, flashlights wrapped in tape to protect the lenses. The lighting created pools of brightness surrounded by shadow. You could see your workstation clearly. Everything else existed in varying degrees of darkness. Ventilation was worse than the main assembly area.

Hangar 7 had been designed for storage and repair work, not continuous production. The air circulation system moved air at onethird the rate of the main building. Metal dust hung in the air like fog. Aluminum particles from drilling and grinding. Steel fragments from cutting operations. The workers wore cloth masks, but the masks only stopped the largest particles.

By the end of each shift, everyone’s lungs felt coated. The noise was identical to the main floor. Metal on metal. Pneumatic hammers firing 60 times per minute. The hiss of compressed air bleeding from connections. The grinding sound of drill bits cutting through aluminum. The hydraulic wine of the overhead trolley system. The building breathed like a machine that never rested.

After the first week, most workers lost the ability to hear highfrequency sounds. Their ears adapted to continuous assault by simply shutting down certain ranges. Conversation required shouting even when you stood 2 ft away from someone. Most communication happened through hand signals and rhythm. The work assignments were precise teams of six workers per fuselage section.

Two riveters, two buckers, one inspector, one logistics coordinator. The roles were designed for interdependence. No one person could complete a section alone. Each section required 4,800 rivets installed to tolerances measured in thousandth of an inch. The rivet holes were pre-drilled by machines, but the rivets themselves had to be installed by hand.

Each rivet had to be inserted at exactly 90° to the surface. The bucking bar had to be held flush against the manufactured head while the hammer struck the driven head. The force had to be consistent. Too little pressure and the rivet wouldn’t form properly. Too much and the aluminum around the hole would crack. A single misaligned rivet could compromise structural integrity at 25,000 ft altitude.

At that height, the air pressure inside the fuselage was three times the pressure outside. The aluminum skin had to hold that differential across the entire surface area. One weak rivet could start a crack. One crack could propagate across multiple panels. Catastrophic structural failure could happen in under 6 seconds.

The workers knew this. They were told during training an inspector held up a failed rivet and said this killed 10 men over Hamorg there was no margin for error. There was also no assumption these workers could succeed. The training period lasted 3 days. White supervisors from the main assembly line were rotated in to provide instruction.

Most of them resented the assignment. They arrived late and left early. Some refused to demonstrate techniques more than once. When a black worker asked a question, the supervisor would often ignore it or respond with deliberate vagueness. One supervisor, when asked to explain the proper angle for installing a rivet on a curved surface, said, “You’ll figure it out or you won’t.” Then he walked away.

The assumption was that black workers lack the precision required for aircraft assembly. This assumption had shaped American industry for generations. Black workers were considered suitable for manual labor, loading, hauling, cleaning, work that required strength but not skill. The idea that they could master the fine motor control and spatial reasoning required for aircraft assembly was considered improbable at best.

That assumption was about to be tested at scale. The workers in Hangar 7 understood whatwas being assumed about them. They also understood that failure would confirm the prejudice. Success might not change minds, but failure would reinforce them. So, they trained themselves. After the supervisors left, the workers stayed. They practiced on scrap aluminum sections set aside for waste.

They taught each other. The riveters who picked up the technique quickly showed the others. They developed pneummonics to remember sequences. They created their own quality standards that exceeded the official specifications. On the first night of full production, February 15th, 1943, Hangar 7 completed eight fuselage sections. The target was 12.

Each section took an average of 7 hours to complete. The workers had aimed for six. They fell short. The main assembly line with twice the workforce and better equipment and supervisors who had trained for months instead of days completed 14 sections. Management considered the night shift a failure. They scheduled a review for the end of the week.

If production didn’t improve, the experiment would end. The workers would return to their previous assignments as janitors and material handlers. The bottleneck would remain. Ford would continue missing its contractual obligations, but at least the social order would be preserved. By February 22nd, 7 days later, Hangar 7 completed 17 sections.

The mainline completed 16. The reversal happened because the workers in Hangar 7 stopped trying to replicate the methods they’d been taught. They developed their own approaches. The riveting teams realized that the standard technique designed for workers operating in good lighting on easily accessible surfaces didn’t work in the cramped, poorly lit interior of a fuselage section. So, they modified it.

They learned to rivet by sound and feel instead of sight. The bucker inside the fuselage couldn’t see the driven head of the rivet. He learned to feel the vibration pattern through the bucking bar. A properly formed rivet produced a specific frequency. An improper one felt different.

The experienced buckers could identify a bad rivet by the fourth hammer strike and signal the riveter to stop. They also changed their working positions. The official training taught workers to stand perpendicular to the work surface. But inside a fuselage section, there often wasn’t room to stand at all. The workers learned to rivet while crouched, while kneeling, while lying on their backs with their knees braced against structural ribs.

They learned to hold the pneumatic hammer at angles the training manual said were impossible. They made the impossible routine. The inspectors developed their own techniques. Most of them had no formal engineering training. They’d been promoted from the riveting teams because they demonstrated an intuitive understanding of how metal behaved under stress.

They learned to identify stress fractures by running their hands along seams. Metal that was about to fail felt different. It vibrated at a slightly different frequency when tapped. The inspectors carried small hammers and they would tap each rivet and listen. A solid rivet sounded clean. A loose one produced a hollow tone.

By March, the inspectors could check a 100 rivets in under 10 minutes and identify every single flaw. No one at Ford’s management acknowledged the reversal. The production reports were filed separately. Hangar 7’s output was classified under auxiliary assembly rather than primary production. This allowed management to meet contractual obligations to the Army Air Forces without publicly crediting the workers who made it possible.

The reports sent to Washington showed Willow Run meeting its quotas. The reports didn’t specify which assembly line produced which components. The bureaucratic fiction was maintained. Quality control reports from March 1943 show something remarkable. Hangar 7’s rejection rate was 3.2%. The main assembly line’s rejection rate was 8.7%.

Fewer sections required rework. Fewer rivets failed inspection. The sections coming out of hangar 7 were structurally superior by every measurable standard. The night shift workers weren’t just faster, they were better. This efficiency wasn’t accidental. The workers in Hangar 7 understood what was at stake.

Every fuselage they built would carry 10 men into combat. a pilot, a co-pilot, a bombardier, a navigator, a flight engineer, a radio operator. Four gunners, 10 men whose survival depended on whether the rivets held when the aircraft hit turbulence at 25,000 ft or when German anti-aircraft fire punctured the fuselage or when the entire plane shook from the recoil of its own weapons.

If the rivets failed, those men died. Not in abstract future combat, but in immediate catastrophic structural failure. The fuselage would tear open. The aircraft would break apart in midair. 10 men would fall four miles to their deaths. There was no room for the luxury of resentment. The work demanded precision. They delivered it. But theydelivered more than that.

They delivered a level of care that exceeded what was required because they understood that their work was a form of moral statement. Every perfect rivet was proof. Every completed section was evidence. They were building more than bombers. They were building an argument. By April 1943, Hangar 7 was outproducing the main assembly line by 22%.

21 fuselage sections per day compared to 17. Ford’s production office began quietly shifting more work to the night shift. Wing assembly, tail section fabrication, bomb bay door installation, nose turret mounting brackets. The official explanation was efficiency optimization. The real reason was that the workers in Hangar 7 were faster, more reliable, and less likely to walk off the job over contract disputes.

The main assembly line had gone on strike twice in early 1943, both times over integration issues. White workers refused to work alongside black workers in skilled positions. The United Auto Workers Local 50 supported the strikes. The union argued that integrating the assembly lines would undermine worker solidarity and create tension that would hurt production.

The strikes lasted 3 days each. Production stopped completely. The army air forces threatened to cancel contracts. Ford management negotiated by agreeing to keep the assembly lines segregated. Hangar 7 never stopped. The night shift understood that stopping meant losing the only opportunity they had to prove their capability.

They worked through both strikes. While the main assembly line sat silent, Hangar 7 ran at full capacity. If you’re still watching, thank you. Stories like this take time to research and produce. If you’d like to see more untold histories from the Second World War, subscriptions help make that possible. The secrecy surrounding Hangar 7 wasn’t just internal policy.

It was enforced systematically. Photographers were prohibited from entering the building. Security guards at the entrance had explicit instructions. No cameras beyond this point. No exceptions. Newsre teams filming at Willow Run for the Office of War Information were directed away from the northern hangers. When they asked what was in those buildings, they were told it was classified repair work.

Not technically a lie, but not the truth either. The official narrative of Ford’s war production featured white workers exclusively. This wasn’t oversight. It was orchestrated. The War Production Board worked with the Office of War Information to create a specific image of American industry at war. That image required showing America’s factories staffed by workers who looked like the audiences watching the news reels in movie theaters.

White workers, male workers, workers who fit the acceptable definition of who built American power. Black workers assembling bombers didn’t fit the image the government wanted to project. The Roosevelt administration needed public support for the war effort. That support depended on maintaining certain assumptions about American capability.

One of those assumptions was that black Americans worked in support roles, not production roles. They could load bullets, but they didn’t make them. They could clean aircraft, but they didn’t build them. Showing black workers doing skilled technical work would challenge that assumption. The administration decided the challenge wasn’t worth the risk.

But the planes didn’t care who built them. Aircraft don’t recognize prejudice. Metal doesn’t know the color of the hands that shaped it. Rivets hold or they don’t. Welds fail or they don’t. The laws of physics are morally neutral. By June 1943, onethird of all B24 fuselage sections leaving Willow Run came from hangar 7. Those sections were integrated into aircraft that flew missions over occupied Europe.

They became part of bombers with tail numbers that appeared in official records. Aircraft that were photographed over Germany. Aircraft that were documented in afteraction reports filed by crews who flew them. Aircraft that were celebrated when they returned home. None of the coverage mentioned where the fuselages were made.

None of the records listed the workers who built them. The crews who flew those bombers never knew. When they walked around their aircraft during pre-flight checks, running their hands along the fuselage skin, checking the rivets, they had no idea those rivets had been installed by workers who weren’t allowed to drink from the same water fountains as the dayshift workers at the same factory.

There was one exception. In May 1943, an Army Air Force’s officer named Colonel James Atwood visited Willow Run to inspect production quality. His assignment was to determine why B24s from Willow Run had a lower mechanical failure rate than B-24s produced at the Consolidated plant in San Diego. The data showed a measurable difference.

Willowr run aircraft suffered fewer structural failures in combat, fewer emergency landings due to equipment malfunction.The difference was small but consistent across hundreds of aircraft. Colonel Atwood was sent to find out why. He toured the main assembly line first. He spent 6 hours watching the production process. He interviewed supervisors.

He reviewed quality control reports. He found nothing unusual. Then he asked to see the auxiliary hangers. Management tried to redirect him. They offered to show him the experimental modifications section. They suggested a tour of the paint facility. Atwood insisted on seeing all production areas. He entered hangar 7 at 2:00 a.m.

on May 12th, 1943. He stayed for 4 hours. He didn’t announce himself. He walked the floor like any other inspector. He watched the riveting teams. He saw workers installing rivets in darkness using techniques he’d never seen in any training manual. He watched an inspector identify a stress fracture by touch alone.

He picked up a completed fuselage section and examined the rivet pattern. Every rivet was flush. Every seam was clean. He pulled out a feeler gauge and checked the gaps between panels within tolerance. every single measurement. He inspected completed sections waiting for transport. He found one with a repair tag, a section that had been rejected during initial inspection and sent back for rework.

He examined the repaired area. He couldn’t find the repair. The rework had been done so precisely that the repaired section was indistinguishable from the original manufacturing. He asked a supervisor about the repair procedures. The supervisor showed him the log. The repair had taken 45 minutes.

The same repair on the main assembly line typically took 3 hours. Colonel Atwood reviewed the quality control logs. He compared them to the logs from the main assembly line. The data was clear. Hangar 7’s sections were superior by every metric. Fewer rejections, faster repairs, better precision. He asked the supervisor how this was possible.

The supervisor said the night shift workers were highly motivated. Atwood asked why they were on the night shift instead of the main line. The supervisor didn’t answer. Atwood’s report filed on May 18th, 1943 stated that Hangar 7’s production standards exceeded the main assembly line in every measurable category. He recommended expanding the night shift operation.

He suggested transferring the best practices observed in hangar 7 to the main assembly line. He recommended recognizing the night shift workers with commendations for exceptional production quality. His report was 18 pages long. It included detailed technical analysis. It included photographs of the work he’d observed.

It included specific recommendations for implementation. The recommendation was ignored. Expanding Hangar 7 would require acknowledging its existence. That acknowledgment would raise questions. Ford’s management and the War Production Board weren’t prepared to answer. Questions about why skilled workers had been restricted to night shifts.

Questions about why the best production numbers were being generated by workers who weren’t allowed to use the same facilities as other workers. questions about what it meant that the official narrative of American war production was systematically excluding the people doing some of the best work. Those questions didn’t have acceptable answers, so they weren’t asked.

The night shift remained classified as auxiliary work. The workers remained invisible. Colonel Atwood’s report was filed and forgotten. It wouldn’t be rediscovered until 1993 in a box of declassified War Department documents donated to the National Archives. Inside Hangar 7, the rhythm never changed. Midnight to 8:00 a.m. 6 days a week, sometimes seven when production demands increased.

The same teams, the same stations, the same sound of metal shaping metal. The workers developed a culture separate from the main factory. They brought food from home and shared meals during the 3:00 a.m. break. Cornbread, fried chicken, collarded greens kept warm in thermoses. They ate together at makeshift tables constructed from wooden pallets and scrap aluminum.

They talked about their families, about the war, about what they would do when it ended. They sang while they worked, not loud enough to disrupt production, but loud enough to maintain morale. Gospel hymns, mostly work songs with rhythms that matched the pace of the riveting. Sometimes someone would start a song and the entire hanger would pick it up.

The sound would weave through the industrial noise. Human voices synchronized with machine percussion. The songs weren’t recorded. The traditions weren’t documented. But they existed. They were real. They mattered to the people who shared them. One worker, a riveter named Thomas Crawford, kept a personal journal. He’d been a teacher before the war, history and English at a segregated high school in Detroit.

He joined Willow Run in January 1943 because the pay was better and because he wanted to contribute to the war effort. He expected to work in themail room or the cafeteria. Instead, he was assigned to Hangar 7. He wrote in his journal during breaks. The entries were brief, factual. He wrote like he was documenting evidence for a future trial.

February 20th, 1943. Finished 19 sections tonight. Hands still shaking. The pneumatic hammer vibrates everything. Can’t hold a pencil steady anymore. Worth it. March 5th, 1943. Inspector found a crack I missed during initial riveting. stress fracture along the frame joint. I would have signed off on it. He caught it.

That crack would have killed 10 men at altitude. Won’t happen again. April 12th, 1943. Heard they’re sending our sections to England to the Eighth Air Force. Hope they hold. Hope the crews come home. Nobody here will ever know whether our work saved lives or not, but we’ll know we did everything possible to make it right. The journal wasn’t discovered until 1989 in a box of his belongings donated to a local historical society by his daughter after Crawford died.

It’s one of the few firstirhand accounts of Hangar 7 that still exists. The entries reveal something the official records don’t. The workers knew their contributions were being erased in real time. They understood that the planes they built would be credited to others. Crawford wrote about this explicitly. He understood the injustice.

But he also understood something more important. Crawford wrote on July 3rd, 1943, “Nobody’s going to remember us. That’s fine. The boys in those planes will come home. That’s what matters.” By August 1943, Hangar 7 employed 5,200 workers. The expansion happened quietly. New workers were recruited from Detroit’s black neighborhoods with promises of steady employment and skilled labor positions.

The pay was the same as the main assembly line. The conditions were worse. The opportunity was unprecedented. Applications exceeded available positions by a factor of seven. The workers who were accepted understood they were participating in something larger than a job. They were disproving a lie that had shaped American industry for generations.

The production numbers tell part of the story. Between February 1943 and August 1945, Hangar 7 produced 8,400 fuselage sections, 3,200 wing assemblies, and 1,900 complete tail sections. Those components were integrated into B-24 Liberators that flew 28,000 combat missions. The bombers that carried sections built in Hangar 7 dropped 180,000 tons of ordinance on strategic targets across Europe and the Pacific.

12 Medal of Honor recipients flew in aircraft that contained parts assembled by the night shift at Willow Run. None of them ever knew who built the planes that kept them alive. The war ended in August 1945. Willow Run’s production contracts were cancelled within a week. The main assembly line shut down on August 20th.

Hangar 7 closed on August 22nd. The workers were given two weeks severance pay. No ceremony, no acknowledgement, no record of their service beyond payroll documents that listed them as general laborers. Ford Motor Company’s official history of Willow Run, published in 1946, makes no mention of Hangar 7.

The production statistics are attributed to the main assembly line. The photographs in the company archives show only white workers. This wasn’t an accident of history. It was an active eraser. Some of the workers from Hangar 7 tried to stay in skilled manufacturing after the war. Most were turned away. The skills they had demonstrated during the war didn’t translate into post-war opportunities.

Union locals that had tolerated their presence during the national emergency reverted to exclusionary practices once the crisis passed. The jobs they had held at Willow Run disappeared. The recognition they deserved never arrived. Thomas Crawford returned to his pre-war job as a janitor at a Detroit elementary school.

He never spoke publicly about his work at Willow Run. His journal discovered decades after his death contains one final entry dated August 23rd, 1945. It’s over. We did what they said we couldn’t. Nobody cares. But we know in 1997 a researcher named Dr. Angela Morrison began investigating discrepancies in Willow Run’s production records.

She noticed that the documented output from the main assembly line didn’t match the number of B24s that were actually delivered. The numbers were off by thousands of components. She requested access to Ford’s internal production archives. Most of the documents related to auxiliary operations had been destroyed in a 1958 warehouse fire, but she found payroll records, time cards, shift assignments. She found hanger 7.

Morrison spent 3 years tracking down survivors. She interviewed 42 former workers from the night shift. Most of them were in their late 70s or early 80s. Some had never told their families about the work they did during the war. One man interviewed in 1999 said he didn’t think anyone would believe him. Another said he assumed it didn’t matter anymore.

Morrison’s research was published in2001 under the title The Invisible Assembly line, Africanamean Workers and the Mass Production of the B-24 Liberator. The book received limited attention. It wasn’t reviewed in major publications. It didn’t prompt any official recognition from Ford Motor Company or the United States government.

But it did something more important. It confirmed that what happened in Hangar 7 actually happened. In 2010, the Smithsonian’s National Museum of African-American History and Culture added a small exhibit about Willow Run’s night shift. The exhibit includes Crawford’s journal, photographs of Hangar 7 taken after the war, and a fragment of a B-24 fuselage with rivets still intact.

The plaque describes the workers as essential contributors to America’s industrial war effort. It’s accurate. It’s insufficient, but it exists. The rivets are still holding. If this story mattered to you, consider subscribing. History doesn’t remember itself. We have to do that work. Every subscription helps ensure these stories continue to be told.

Thank you for watching.

News

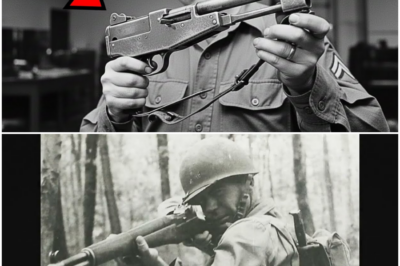

The $16 Gun America Never Took Seriously — Until It Outlived Them All DT

The $16 gun America never took seriously until it outlived them all. December 24th, 1944. Bastonia, Belgium. The frozen forest…

Inside Seneca Shipyards: How 6,700 Farmhands Built 157 LSTs in 18 Months — Carried Patton DT

At 0514 a.m. on April 22nd, 1942, the first shift arrived at a construction site that didn’t exist three months…

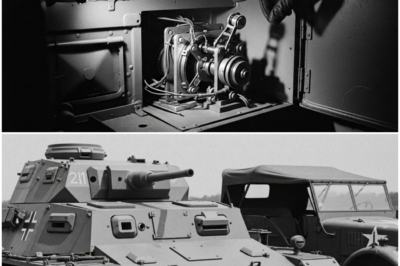

German Engineers Opened a Half-Track and Found America’s Secret DT

March 18th, 1944, near the shattered outskirts of Anzio, Italy, a German recovery unit dragged an intact American halftrack into…

They Called the Angle Impossible — Until His Rifle Cleared 34 Italians From the Ridge DT

At 11:47 a.m. on October 23rd, 1942, Corporal Daniel Danny Kak pressed his cheek against the stock of his Springfield…

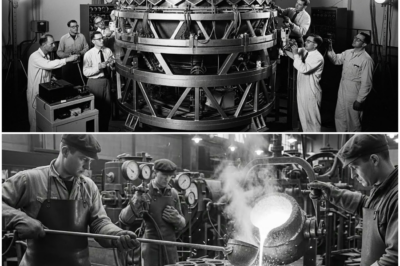

The Trinity Gadget’s Secret: How 32 Explosive Lenses Changed WWII DT

July 13th, 1945. Late evening, Macdonald Ranchhouse, New Mexico. George Kistakowski kneels on the wooden floor, his hands trembling, not…

America Lost Malaysian Tin in 1942 — So Engineers Reinvented The Soup Can DT

February 15th, 1942. Singapore. When British Lieutenant General Arthur Persal surrendered Singapore to Japanese forces, 85,000 Allied troops became prisoners…

End of content

No more pages to load