Dakota Territory, 1886. While neighbors rushed to finish their log cabins before winter, one Norwegian homesteader was just getting started on something they’d never seen. He built a second wall around his entire cabin 12 in out from the logs filled with loose hay and moss. His neighbors called it a fence around a house.

They called him wasteful. A perfectly good single wall cabin with tight chinking was all any man needed, they said. He kept building anyway, adding vents at the eaves and a drip gap at the base while they shook their heads. Then the winter of 1886 arrived early.

Blizzard winds hit 35 m hour, driving snow through every gap and crack. Inside standard cabins, water froze solid in pales just feet from the fire. Families burned through cord after cord of wood and still woke to 5° below zero indoors. But that Norwegian’s cabin with the ridiculous second wall. Dawn after dawn, his interior stayed 21° warmer than his neighbors measured and recorded.

What did he understand about wind, dead air, and heat loss that everyone else dismissed as foolish excess? If you value stories of practical wisdom that stood the test of time, make sure to subscribe. We’ve got more documented accounts worth remembering. The Norwegian arrived in Dakota territory in late spring of 1886 with two trunks, a crosscut saw, and ideas about walls that his new neighbors would spend months ridiculing.

Olsen had grown up along Norway’s coast, where winter winds cut through valleys like knives, and he’d learned early that a single barrier rarely stopped what the weather wanted to take. His father had built fish drying sheds with double planking and dead air spaces, and Olsen himself had worked summers at the Bergen Ice House, where they packed sawdust between inner and outer walls to keep winter locked inside through July heat.

Now staking his claim on the high plains, where wind had nothing to stop it for 1,000 mi. He planned to build the same way. By late June, Olsen had his logs up, a 14 by8 ft cabin with 9- ft walls chinked tight and solid like every other homestead in the township. His neighbors nodded approval and expected him to move on to breaking sod and setting fence posts.

Instead, he began setting cedar pickets 36 in apart in a perfect rectangle 12 in outside his log walls. The road overseer, a man named Haric, who’d been on these planes since 1878, stopped by on his weekly rounds and asked what in creation Olsen was building now. “Stormwall,” Olsen said, checking his plumb bob against a picket. “Like they do for ice storage.” Har spat tobacco juice and shook his head.

“That’s a fence around a house. Waste of good lumber.” But Olsen kept working. He cut ledger blocks from 2×4 stock and nailed them between the pickets every 48 in to keep his outer frame true and steady. At turtle the base, he left a 3/4 in gap for drainage and screened it with woven wire to hold his fill material in place.

The whole framework took him 4 days of careful measuring and cutting. And by then, word had spread through the township that the Norwegian was building something peculiar. The outer skin went up in vertical planks, 1×10 roughson boards that Olsen had ordered special from the Jamestown mill. He ran them floor to eve and battened every seam with 1×3 strips spaced 16 to 18 in apart.

At the roof line, he built a small overhang and flashed it with tin to shed snow melt away from the cavity. Under the eaves, he left a half-in vent slot to let moisture escape from whatever he planned to stuff between the walls. Looks like a stockade for a house,” said Martha Brennan, the district school teacher, when she rode past in early August.

“But she said it with curiosity rather than mockery, and she stopped to watch him work.” “Dead air,” Olsen explained, gesturing toward the 12-in gap. “Moving air steals heat. Trapped air holds it.” He’d learned this principle not just from iceous, but from conversations with a Lakota woman who traded sewn goods at the general store.

She told him about tepee liners, inner walls of cloth that created a calm space between the windcatching outer hide and the people inside. The liner trapped a band of still air that stayed warmer and eliminated the drafts that made winter camps unbearable. Olsen had studied her description and realized he could build the same principle into rigid walls.

Through late August and into September, while his neighbors finished harvest and began laying in firewood, Olsen cut and dried prairie hay. He built drying racks from scrap lumber and spent days gathering moss from creek bottoms, spreading it thin to cure in the sun. The hay he cut short and loose, knowing he needed material that would trap air without packing down solid.

He calculated roughly 120 cubic feet of fill for the cavity around his cabin walls, and he wanted every bit of it dry as paper and light as possible. That hail rot by Christmas, predicted Harwick during another visit. Mice will nest in it. You’ll have the whole wall full of vermin. Ice houses use sawdust, Olen replied. Stays dry if you vent it right.

By October, the mockery had settled into a steady pattern. Every man in the township had an opinion about the fence around Olsen’s house, and none of the opinions were favorable. They called it wasteful because he’d used 1,200 board feet of lumber for an outer skin that served no structural purpose.

They called it foolish because everyone knew tight chinking and a hot fire were all any cabin needed. They called it excessive because the gap between walls was wide enough to walk through, and who needed that much dead space around a perfectly good log house? But Olsen kept working.

He filled the cavity carefully, tamping the loose hay and moss to approximately 3 to four pounds per cubic foot, dense enough to stay put, but light enough to trap maximum air. At the top of each wall section, he tacked muslin as a windcheck to prevent the fill from settling and creating cold spots. For doors and windows, he hinged the outer planks like shutters so they could swing open for access, but seal tight against weather.

The work took him two months total, which was 6 weeks longer than most men needed to finish a cabin completely. His neighbors watched him labor through September heat and into October cold, shaking their heads at the time and money he was throwing at a problem that didn’t exist.

When the first snow dusted the ground in mid-occtober, and Olsen was still adjusting his eve vents and door seals, they figured they’d have proof soon enough that one good wall was better than two poor ones. What they didn’t understand was the physics Olsen had learned from ice storage and adapted from Plains Indian wisdom. A blizzard wasn’t just cold. It was moving air under pressure.

That movement created infiltration through every gap and crack, overwhelming whatever insulation a single wall might provide. But a sacrificial outer skin could take the wind’s force while a dead air cavity broke its circulation. The principles were sound, the materials were proven, and the measurements were precise. By first snow, Olsen’s cabin was ready to demonstrate what his neighbors dismissed as the winter delusion of a stubborn immigrant who didn’t know when to quit building. The first test came earlier than anyone expected.

October 15th brought 3 ft of powder snow in 18 hours, driven by winds that bent fence posts and stripped bark from cottonwoods. The storm arrived without the usual warning signs. No Mar’s tales in the western sky. no drop in barometric pressure that old-timers could feel in their bones. One day the prairie lay brown and ready for winter, the next it disappeared under drifts that reached cabin eaves and buried wagon ruts completely.

Harwick woke that first morning to find ice an inch thick in his water pale, sitting just 4 feet from his banked stove. The interior walls of his cabin wore a coating of frost, where his breath had condensed and frozen during the night. He rekindled his fire with shaking hands and watched the flames struggle against drafts that seemed to come from every direction at once.

Outside, the wind howled at sustained speeds above 35 mph, with gusts that rattled his door in its frame and sent puffs of snow through gaps he’d thought were sealed tight. By dawn, Harwick’s thermometer read 22° below zero outside, but inside his cabin felt barely warmer than freezing.

He’d burned through his evening firewood allocation and half of the next day’s supply just trying to maintain enough heat to prevent his water from turning solid. The problem wasn’t his stove or his wood. It was the wind driving cold air through every microscopic crack in his single wall construction while simultaneously sucking heated air out through other gaps on the leeward side.

Martha Brennan faced the same physics at her cabin a mile south. She’d banked her fire carefully before bed, leaving a bed of coals that should have lasted until morning. Instead, she woke to a cold stove and interior temperatures that made her breath visible in cloudy puffs.

Ice had formed on the inside surface of her logs, creating a crystalline coating that grew thicker as her body heat met the frozen wood. She wrapped herself in every quilt she owned, and struggled to restart her fire with fingers so stiff she could barely strike a match. The mechanism destroying their comfort was invisible but relentless.

Blizzard winds create pressure differentials that turn any structure into a giant bellows. Air gets forced through the tiniest gaps on the windward side while heated interior air gets sucked out through openings on the Lee. A single log wall, no matter how carefully chinkedked, presents hundreds of potential infiltration points where wind driven cold can penetrate.

The logs themselves become thermal bridges, conducting exterior cold directly to interior surfaces where it radiates into living spaces. 3 mi northeast, the midwife Sarah McKenna was making her rounds between homesteads, checking on families with young children and elderly members who couldn’t survive extended exposure to subfreezing indoor temperatures.

At the Johansson place, she found the family huddled together in one corner, burning chair legs to supplement their dwindling firewood supply. The baby’s lips had taken on a bluish tinge despite being wrapped in wool blankets. At the Morrison cabin, the old grandfather sat so close to the stove that his clothes nearly caught fire. Yet his hands remained too cold to hold a coffee cup steadily. Each cabin told the same story of thermal defeat.

Families were burning 1 and a half to twice their normal evening wood allocation just to raise interior temperatures to 40 or 45° by bedtime. Water pales froze solid overnight despite being placed near stoves. Moisture from cooking and breathing condensed on interior walls and froze into sheets of ice that made the logs themselves feel colder to the touch.

The wind wasn’t just lowering exterior temperatures. It was actively pumping heat out of supposedly sealed structures. Meanwhile, at Olsen’s doublewalled cabin, a different set of physics was playing out. The Norwegian had banked his fire the same way as his neighbors, with the same amount of wood in the same careful arrangement of coals, but his outer plank wall was taking the wind’s full force, creating turbulence and pressure relief in the 12-in cavity filled with loose hay and moss.

The actual log structure sat in relatively still air, protected from the convective pumping that was defeating every other cabin in the township. The loose fibrous fill in Olsen’s wall cavity was performing exactly like the sawdust and tan bark used in commercial ice houses. Each strand of hay and clump of moss created tiny air pockets that couldn’t circulate freely.

Moving air steals heat through convection, but trapped air, held motionless by fibrous material, becomes an insulating barrier. The principle was so fundamental that ice house operators had relied on it for decades to preserve winter ice through summer heat, and now it was working in reverse to preserve winter heat through blizzard cold.

By the third day of the storm, the temperature differential had become impossible to ignore. Harwick made the bitter trudge through kneedeep snow to check on his Norwegian neighbor, expecting to find Olsen in the same desperate straits as everyone else. Instead, he found the immigrant calmly splitting kindling in his cabin, working in shirt sleeves, while snow continued to pile against his outer walls.

Olsen’s water pail showed no ice formation. His interior walls remained free of frost. Most remarkably, his evening fire had lasted through the night with enough coals remaining to restart easily at dawn. The contrast was so stark that Harwick initially suspected some trick, a hidden stove or secret fuel source that explained the impossible warmth. The explanation was simpler and more profound.

Dead air trapped between fibrous materials creates an insulating barrier that wine cannot penetrate. The outer wall absorbed the storm’s mechanical energy while the inner wall remained in a zone of thermal stability. This wasn’t magic or luck. It was applied physics that any ice house foreman could have explained.

Adapted by a man who understood that the same principles preserving cold in summer could preserve heat in winter. The storm raged for seven more days, and with each dawn, the difference became more pronounced. Single wall cabins were losing the battle against infiltration, while Olsen’s double shell was winning it through superior engineering disguised as excessive construction.

On the fourth morning of the blizzard, Olsen began keeping a ledger. He’d noticed Martha Brennan’s careful recordkeeping during her visits to measure school children’s progress, and he understood that numbers would carry more weight than claims when his neighbors finally asked how his cabin stayed warm.

Each dawn at 6:00, he recorded paired temperature readings using a mercury thermometer he’d purchased from the Jamestown hardware store. One measurement at the outer sill where his plank wall met the ground. Another at the interior log surface 3 ft from his stove. The results were consistent and dramatic.

On October 19th, with his stove banked to coals since midnight, the outer sill read 14 degrees below zero, while the interior log wall registered 7° above, a 21° difference. October 20th showed similar results, -6 outside the planks, plus 5 at the inner logs. Day after day, the temperature differential held between 17 and 23° with the best single reading reaching 21° of protection.

Harwick arrived on the seventh day, desperate enough to ask direct questions. He found Olsen writing figures in a small leather notebook, carefully documenting what seemed impossible. “How’s your fire lasting all night?” Harwick demanded. His own cabin required constant feeding to maintain any heat at all. Olsen showed him the smoke test first.

He lit his pipe and blew a stream of smoke toward the outer wall, where it immediately bent horizontal and disappeared through invisible gaps between the planks. Then he repeated the test at the interior log surface, holding a feather near the chinking, the feather barely stirred. “Outer wall takes the wind,” Olsen explained.

“Inner wall sits in still air.” The physics were becoming clear through demonstration. The 12-in cavity filled with loose hay and moss was creating what ice house operators called a cold buffer, a sacrificial zone that absorbed the storm’s energy before it reached the structural wall. Commercial ice houses used the same principle with sawdust or tan bark packed between inner and outer partitions.

The fibrous fill trapped air in countless tiny pockets, preventing the circulation that would otherwise pump heat away through convection. Harwick studied Olsen’s fuel consumption with growing disbelief. The Norwegian’s evening wood bundle, measured by the arm load and stacked for counting, was 35 to 45% smaller than what Harwick needed to achieve the same interior temperature.

Both men aimed for 52 to 55° by 8:00 each evening, a reasonable target for frontier comfort. But where Harwick burned six to eight split logs reaching that goal, Olsen needed only four or five pieces of similar size. The difference lay in heat retention rather than heat generation. Harwick’s single wall cabin was fighting constant infiltration with cold air streaming through microscopic gaps while warm air escaped through others. His stove worked against a continuous thermal drain that made efficient heating impossible.

Olsen’s double wall had eliminated that drain by creating a dead air barrier that wind could not penetrate. Martha Brennan arrived on the eighth day to document the phenomenon herself. As the district school teacher, she kept weather records for the territorial government and understood the value of systematic measurement.

She brought her own thermometer and spent an hour taking readings at various points around both cabins. At Harwick’s place, she recorded interior lows of minus5 to + 5° just before dawn with ice forming in water pales throughout the night.

At Olsen’s cabin, she found steady readings between + 10 and +4° at the same pre-dawn hour with no ice formation anywhere inside. The mechanism deepened under scrutiny rather than falling apart. Modern understanding of insulation centers on trapped air. The principle that motionless air creates thermal resistance while moving air destroys it. Straw bale construction developed decades later would demonstrate R values of 1 to 2 and 4/10 per inch by using dense straw to trap air in fibrous matrices.

Olsen’s loose hay and moss, while less dense, operated on identical physics. Each strand created microscopic air pockets that couldn’t circulate freely, building thermal resistance through stillness rather than density. The analogy to tippy liners became more relevant as the storm continued. Plains tribes had used inner cloth walls for generations, creating a 3 to 9 ft gap that trapped calm air and controlled drafts.

The principle was identical, an outer skin to catch the weather, an inner wall for living, and dead air between them for thermal protection. The Lakota woman who’d explained liner construction to Olsen at the general store had unknowingly described the same physics that made ice house insulation work. By the 10th day, Olsen’s temperature differentials were averaging plus 18 to plus 20° between outer and inner wall surfaces.

His fuel savings remained consistent at roughly 40% less wood consumption for equivalent interior comfort. Most importantly, his cabin maintained livable conditions without the desperate measures his neighbors were adopting.

Burning furniture, sleeping fully clothed under multiple blankets or abandoning outlying rooms to concentrate heat in single spaces. The storm finally broke on October 22nd, leaving the township buried under drifts that would take weeks to melt. But the thermal lessons were permanently recorded in Olsen’s ledger and in the memories of neighbors who had experienced the difference between fighting the wind and deflecting it.

The double wall had proven itself not through theory, but through measurable performance during the worst conditions the Dakota territory could deliver. When Harwick finally asked to see the construction details, Olsen walked him through the method without commentary or self- congratulation. the 12-in cavity, the loose fill at 3 to four pounds per cubic foot, the ventilation slots that prevented moisture buildup, the sacrificial outer skin that took weather damage while preserving the structural logs.

Every element served a measurable function in creating thermal stability that single walls could not match. The killing week had ended, but its lessons would spread through the township as neighbors realized that excessive preparation had proven to be exactly sufficient preparation and that principles borrowed from ice storage and plains Indian wisdom could mean the difference between survival and surrender when winter decided to test what men had built against its fury.

The second storm arrived on November 3rd with 40 mph winds and temperatures that dropped to 38° below zero. This time the crisis was immediate and life-threatening. At the Morrison cabin, the grandfather’s breathing became labored in air so cold it burned his lungs. The Johansson baby developed a rattling cough that worsened each night as interior temperatures fell below freezing despite a fire that consumed their remaining chair legs and half their floorboards.

Sarah McKenna made her rounds on the second day and found conditions that demanded immediate action. At three separate cabins, she discovered families burning their furniture to supplement exhausted wood supplies while water froze solid in containers placed directly beside red-hot stoves.

The wind was driving infiltration so severe that heated air disappeared as fast as fires could produce it. Frostbite was beginning to threaten fingers and toes of children and elderly who couldn’t generate enough body heat to compensate for the thermal drain when families began appearing at Olsen’s door asking for shelter.

He opened his outer shutters without hesitation and walked them through the Y of his construction. Harwick arrived first with his wife and two young sons, followed by the Morrisons carrying blankets and the failing grandfather. The Johansson’s came last, the mother clutching her coughing baby while the father dragged a sack of their remaining possessions through kneedeep snow.

11 people crowded into Olsen’s 14x 18 ft cabin, but the double wall system proved capable of handling the increased load. The Norwegian added extra muslin baffles at the vestibule he’d built around his outer door, creating an air lock that reduced infiltration by another 10 to 15%.

He demonstrated this improvement by holding burning pipe tobacco near the floor at the inner door threshold, where the smoke now deflected less than an eighth of an inch instead of the quarterin movement they’d seen before the baffles went up. The refugee families experienced thermal stability they hadn’t felt in weeks. Water containers remained liquid throughout the night.

Children stopped shivering and could remove their outer coats indoors. The grandfather’s labored breathing eased as he no longer had to work against frigid air that stressed his aged lungs. Most remarkably, the combined evening fuel burn for all 11 people was 30% less per person than what the individual families had been consuming in their failed single wall cabins.

Olsen spent the third day teaching emergency retrofits to neighbors who still clung to their own claims. The technique was simple but effective. Lash staked plank screens 8 to 12 in off the windward walls. Stuffed the gap with loose straw from barn reserves. Then line the interior walls with blankets or muslin to limit drafts.

The materials were crude compared to his planned construction, but the physics remained sound. Harwick implemented the emergency method first using rough boards and bailing wire to create a sacrificial windscreen along his cabin’s north and west faces.

He packed the gap with straw from his livestock feed and hung wool blankets inside to create an additional air barrier. Within 48 hours, his pre-dawn interior temperatures had risen 12 to 16° compared to the previous week’s readings. Not as effective as Olsen’s full double shell, but survivable. The Morrison family followed the same approach on their cabin, focusing their retrofit efforts on the bedroom where the grandfather slept.

They used canvas wagon covers instead of planks for the outer screen and filled the gap with hay salvaged from their summer cutting. The improvement was immediate and measurable. Frost stopped forming on the interior log surfaces, and the old man’s breathing returned to normal rhythms during sleep.

Martha Brennan documented the emergency retrofits with the same careful measurement she’d applied to Olsen’s original construction. Her records showed that even crude temporary double walls produced interior temperature gains of 10 to 18° when winds exceeded 30 mph. The effect was less pronounced during calm periods, but became critical during storm conditions when infiltration reached life-threatening levels.

The Johansson baby recovered within 5 days of moving into Olsen’s cabin, where steady interior warmth allowed her small body to fight off the respiratory infection that had developed in constantly cold air. Sarah McKenna noted that the child’s improvement coincided directly with exposure to consistent temperatures above freezing, something that had been impossible to maintain in the family single wall homestead.

By November 10th, the immediate crisis had passed, but the lessons were permanently embedded in community memory. Families who had experienced thermal stability behind double walls could no longer ignore the fundamental inadequacy of single wall construction in high wind environments.

The emergency retrofits had proven that the principle worked even with crude materials and hasty installation. Olsen’s vestibule modification became a standard recommendation for anyone attempting the double wall method. The airlock effect reduced infiltration at the most vulnerable point, the door threshold, where human traffic created unavoidable gaps. Smoke tests showed that proper vestibule baffles could eliminate most floor level drafts that otherwise undermined interior heating efforts. The social dynamics of the township shifted during those crowded days in Olsen’s cabin. Men

who had mocked the fence around a house found themselves asking detailed questions about gap width, fill materials, and ventilation requirements. The Norwegian answered without criticism or self- vindication, sharing measurements and techniques as practical information rather than personal triumph.

When the second storm finally broke, 11 people had survived severe cold that would have killed some of them in single wall shelters. The grandfather lived, the baby recovered, and families returned to their own claims with firsthand knowledge of what thermal stability felt like.

More importantly, they carried practical methods for achieving that stability using materials and techniques within reach of any homesteader willing to invest the labor. The emergency retrofits remained in place through the rest of winter, providing measurable comfort improvements and fuel savings that validated the double wall principle under realworld conditions.

What had begun as one man’s excessive construction had become a community survival strategy, proven not through argument, but through the simple fact that people stayed warm when wind tried to freeze them. Spring came early in 1887, but by then the request for construction details had already begun.

Harwick was the first to ask, appearing at Olsen’s door in late March with a notebook and a measuring tape. He wanted dimensions, spacing intervals, and a complete bill of materials. Not for himself, he claimed, but for his brother-in-law, who was planning to homestead the following year. Olsen provided the information without commentary.

12-in cavity minimum, cedar pickets at 36-in spacing, ledger blocks every 48 in, 1×10 planks for the outer skin with 1×3 battens, half-in vent slots at the eaves. Martha Brennan made the second formal request, this time for inclusion in her annual report to the territorial education office. She had documented the thermal performance through two major storms and wanted to preserve the technical details for other frontier teachers who might face similar challenges in remote schoolhouses.

Olsen walked her through the entire system, the woven wire screening at the base gap, the muslin windcheck above the loose fill, the tin flashing that shed melt water away from the cavity, the hinged outer shutters that provided storm protection for windows and doors. By summer, three of the seven nearby homesteads had ordered lumber for permanent double wall construction.

The Morrison family committed first, investing in a complete retrofit that would protect their grandfather through another winter. They chose a 14-in cavity instead of 12, using sawdust from the Jamestown mill, where hay was scarce. The wider gap allowed for denser packing while maintaining the dead air principle that made the system effective.

The blacksmith who serviced stoves throughout the township noted practical differences at cabins with double walls. He found fewer smoke back problems and steadier draws because the inner walls sat in calm air rather than fighting constant pressure differentials. His repair visits dropped significantly at doublewalled structures and he began recommending masonry sleeves for stove pipes and better door seals to homesteaders attempting their own versions of Olsen’s method.

Construction details spread through informal networks rather than formal instruction. Neighbors observed each other’s building techniques during barn raisings and harvest cooperation, noting gap widths, fill materials, and ventilation strategies. The Johansson’s opted for a 16-in cavity filled with a mixture of sawdust and moss, reasoning that wider spacing would provide better insulation despite higher material costs.

The Brennan’s chose 12 in, but used all sawdust, following ice house practice more closely than Olsen’s original hay and moss combination. Results from the second winner validated the method across multiple implementations. Martha Brennan kept detailed fuel consumption records for all three double wall cabins, documenting 25 to 40% reductions in evening wood requirements to reach 55° interior targets.

More importantly, none of the retrofitted homes experienced frozen water containers indoors during storm periods, and all maintained pre-dawn temperatures above 10° throughout January’s worst cold snaps. The Johansson baby thrived through her second winter, showing none of the respiratory distress that had nearly killed her the previous year.

Sarah McKenna attributed the improvement directly to consistent interior warmth that allowed the child’s developing lungs to function normally rather than fighting constant cold stress. The grandfather Morrison lived to see spring and credited his survival to sleeping in air that stayed above freezing throughout the night.

Maintenance requirements proved manageable but consistent. Outer plank skins needed rebattening every 3 to 5 years as weather loosened the strips that sealed vertical joints. Hay and moss fill required replacement every 2 to 3 years, particularly after wet seasons when moisture penetrated the cavity despite ventilation slots.

Sawdust fill lasted longer but cost more initially, creating a trade-off between labor frequency and material expense. The method’s reputation spread beyond the immediate township through correspondence networks that connected frontier communities. County agents began including double wall construction details in their agricultural bulletins, treating the technique as proven field practice rather than experimental innovation.

The approach aligned with established ice house insulation methods, giving it technical credibility that helped overcome resistance to frontier improvisation. By 1890, the double wall principle had appeared in formal agricultural extension publications. A correspondent for the Dakota farmer wrote detailed articles on dead air insulation, complete with diagrams showing proper cavity widths, fill densities, and ventilation requirements.

The technique was described as particularly valuable in high wind regions where standard chinking could not prevent infiltration during severe weather events. Modern building science would later validate every aspect of Olsen’s original method.

Dead air remains the fundamental insulating principle in contemporary construction with moving air destroying thermal resistance while trapped air providing it. Fibrous materials like straw continue to demonstrate respectable R values by preventing air circulation within wall cavities. High wind infiltration still overwhelms inadequate thermal barriers, making windresistant construction essential in exposed locations.

The physics Olsson had borrowed from ice house practice and plains Indian wisdom became standard frontier survival knowledge within a decade of his first double wall cabin. Homesteaders throughout the northern plains adopted variations of the method, adjusting cavity widths and fill materials to local conditions while maintaining the core principle of sacrificial outer walls protecting structural inner walls through dead air barriers.

What had begun as one Norwegian’s excessive preparation became documented best practice for extreme climate construction. The method required more initial labor and materials than single wall building, but the thermal performance and fuel savings justified the investment across multiple building seasons. Most importantly, families stayed warm and survived weather that had proven lethal in conventional construction.

The legacy lived in practical terms rather than grand recognition. Children grew up healthy in consistently heated homes. Elderly members survived winters that would have killed them in drafty cabins. Fuel consumption dropped to sustainable levels that preserved precious wood supplies for essential uses beyond heating.

On the plains, where wind never stopped testing what men built against its force, Olsen’s method had taken the teeth out of winter before it could reach the wall where people lived and families endured.

News

Iraqi Republican Guard Was Annihilated in 23 Minutes by the M1 Abrams’ Night Vision DT

February 26th, 1991, 400 p.m. local time. The Iraqi desert. The weather is not just bad. It is apocalyptic. A…

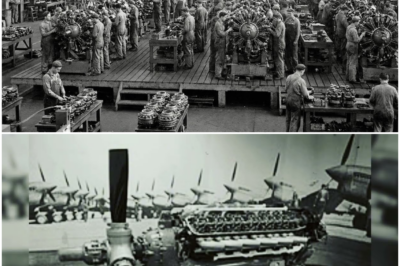

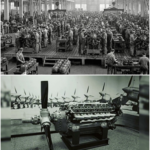

Inside Curtiss-Wright: How 180,000 Workers Built 142,000 Engines — Powered Every P-40 vs Japan DT

At 0612 a.m. on December 8th, 1941, William Mure stood in the center of Curtis Wright’s main production floor in…

The Weapon Japan Didn’t See Coming–America’s Floating Machine Shops Revived Carriers in Record Time DT

October 15th, 1944. A Japanese submarine commander raises his periscope through the crystal waters of Uli at what he sees…

The Kingdom at a Crossroads: Travis Kelce’s Emotional Exit Sparks Retirement Fears After Mahomes Injury Disaster DT

The atmosphere inside the Kansas City Chiefs’ locker room on the evening of December 14th wasn’t just quiet; it was…

Love Against All Odds: How Taylor Swift and Travis Kelce Are Prioritizing Their Relationship After a Record-Breaking and Exhausting Year DT

In the whirlwind world of global superstardom and professional athletics, few stories have captivated the public imagination quite like the…

Taylor Swift and Travis Kelce Swap the Spotlight for the Shop: Inside Their Surprising New Joint Business Venture in Kansas City DT

In the world of celebrity power couples, we often expect to see them on red carpets, at high-end restaurants, or…

End of content

No more pages to load