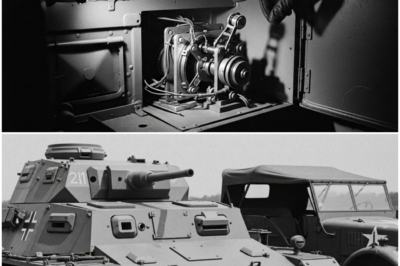

September 1944, Henchel and Sone factory, Castle, Germany. Master craftsman Hinrich Mueller positioned the optical rangefinder assembly into the King Tiger turrets mounting bracket. The device required precise calibration, exactly 1.320 m between lenses.

Mueller had spent 3 hours handitting the brackets to accommodate minor variations in the turret casting. Each rangefinder was individually calibrated, manually adjusted until the optical alignment achieved perfection. Down the production line, another craftsman was hand fitting interleved road wheels, the overlapping suspension system that distributed the King Tiger’s 70 ton weight.

Each wheel required careful spacing, precise shimming, individual adjustment. One wheel took nearly an hour to install correctly. The King Tiger had 18 road wheels per side, 36 wheels total, 36 hours of skilled labor just for road wheels. In the final assembly bay, workers applied zimmerit antimagnetic coating by hand, a cement-like paste that prevented magnetic mines from adhering to armor.

The coating had to be spread evenly, then scored with a special tool to create ridges. The entire hull had to be coated. The process took two full days per tank. At peak production in September 1944, Henchel managed to complete six to seven King Tigers per week. That was their absolute maximum output, about one tank per day when everything went perfectly.

Each King Tiger required approximately 14,000 man hours to build. 300 skilled machinists worked on each vehicle. Parts were hand fitted because tolerances were too tight for mass production. The same week, 4,800 m away in Grand Blanc, Michigan, Fisher Body plant number two, part of General Motors, was completing 25 M4 Sherman tanks every single day.

25 tanks per day. Every day from a single factory, the Fisher body assembly line ran continuously. Every 58 minutes, another Sherman rolled off the production floor. complete, functional, ready for combat. Each Sherman required approximately 1,200 man-h hours to build. The workers were mostly women with 2 weeks of training. The parts were interchangeable. Nothing was hand fitted.

Germany was building one of the world’s most fearsome tanks using 19th century craftsman techniques. America was stamping out adequate tanks using 20th century mass production. The King Tiger was superior in every measurable combat characteristic. The Sherman would win the war anyway, not because it was better, because America could build it faster than Germany could destroy it.

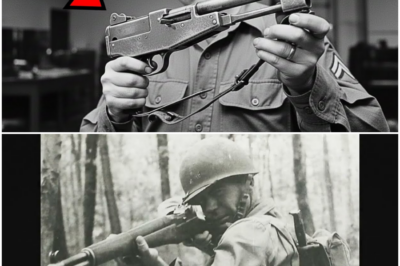

The Panza Kfagen Tiger 2, officially designated Tiger House B, commonly called Koix Tiger, King Tiger, represented the pinnacle of German tank design. Development began in October 1942 as a successor to the Tiger 1. The goal was to combine the Tiger 1’s armor protection with the Panther’s sloped armor design, mounting the devastating 8.8 cm KWK 43 L71 gun.

The specifications were extraordinary. Weight 69.8 tons combat loaded. Armor 150 mm frontal hull 185 mm frontal turret 80 mm sides. Gun 8.8 cm KWK43L71 capable of penetrating 193 mm of armor at 1,000 m. Engine Maybach HL230P30 producing 700 horsepower. Crew five commander, gunner, loader, driver, radio operator. Maximum speed 25.7 mph on roads, 10 to 11 mph cross country.

The King Tiger could engage and destroy any Allied tank from ranges exceeding 2,000 m while remaining effectively immune to return fire when hauled down. Sherman 75mm guns couldn’t penetrate King Tiger frontal armor at any range. Even the Sherman 76mm gun introduced in 1944 required pointblank flank shots for penetration. But building such a tank was extraordinarily difficult.

The Henchel facility at Casle, the only factory authorized to produce King Tigers, employed approximately 8,000 workers at peak production. Only 300 of them were skilled enough to work on King Tiger assembly. These craftsmen had trained for years.

They understood precision machining, metal fatigue characteristics, tolerance stacking, and optical alignment. They could hand fit components to within 0.01 01 mm tolerances. Production began in January 1944. Initial output was pathetic. One tank that entire month. By February, output reached 12 tanks. March saw 19 completed. The learning curve was steep because every King Tiger was essentially customuilt.

The interled road wheel system designed to distribute weight and improve mobility required each wheel to be individually spaced and shimmed. If one wheel was misaligned, the entire suspension had to be disassembled and refitted. In field conditions, if a single inner road wheel broke, mechanics had to remove multiple outer wheels to access it, a process that could take 8 hours under combat conditions.

The optical rangefinder capable of determining target distance to within 100 meters at 2,000 m had to be calibrated for each specific turret. Variations in turret casting meant no two rangefinders could be installed identically. Each required individual adjustment by master optitians. The zimmerit coating applied to prevent magnetic mine attachment was mixed on site to exact specifications.

Workers spread it by hand, scoring it with special tools to create a distinctive riged pattern. The process was labor intensive, timeconuming, and required constant quality control to ensure proper adhesion and thickness. By September 1944, production peaked at approximately 30 King Tigers for the entire month.

That was the absolute maximum Henchel could achieve, about one tank per day, assuming no disruptions, adequate materials, and full staffing. Then came the Allied bombing raids. Five massive air strikes between September 22nd and October 7th, 1944 destroyed 95% of the Henchel plant’s floor space. Estimated loss, 657 King Tigers that could have been built, but weren’t. When production resumed, output never recovered.

By March 1945, when Allied forces captured Kasle and shut down the Henchel facility, only 489 King Tigers had been completed. 489 in 14 months against an order for 1,500 tanks. Each one was a masterpiece of engineering. Each one was tactically dominant and there weren’t enough of them to matter. The M4 Sherman medium tank was never intended to be the best tank in the world.

It was intended to be good enough and produced in overwhelming numbers. Weight 33 tons M4 A2 variant. Armor 51 mm frontal hull 76 mm frontal turret. Gun 75mm M3 early models or 76 millime M1 A2 late models. Engine twin GM 6046 diesel engines M4 A2 producing 410 combined horsepower. Crew 5 commander, gunner, loader, driver, assistant driver.

Maximum speed 26 mph on roads, 15 mph cross country. The Sherman couldn’t match the King Tiger in any direct combat metric. Its armor was inadequate against the 88mm gun. Its gun couldn’t penetrate King Tiger frontal armor. It was lighter, smaller, and individually inferior. But the Sherman had one overwhelming advantage.

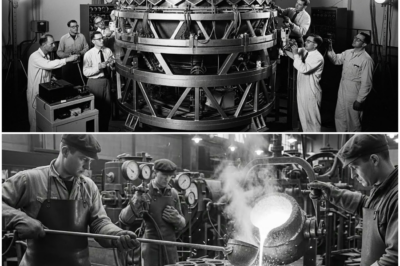

America could build them faster than Germany could destroy them. Fisher Body plant number two in Grand Blanc, Michigan, opened in April 1942 specifically to produce tanks. The 452,000q ft facility was designed from the ground up for assembly line production. General Motors applied every lesson learned from decades of automobile manufacturing to tank production.

The key innovation, interchangeable parts. Unlike German tanks where components were hand fitted to accommodate manufacturing variations, Sherman parts were machined to such precise tolerances that any part could fit any tank. A transmission from one Sherman could be installed in another with no modification.

Road wheels, tracks, turrets, engines, everything was standardized. This standardization transformed production. Fisher Body could hire workers with minimal experience, train them for two weeks, and put them on the assembly line. They didn’t need master craftsmen. They needed people who could read blueprints, operate torque wrenches, and follow assembly procedures.

By late 1943, Fisher Body Grand Blanc was completing one M4 A2 Sherman every 58 minutes, 25 tanks per day, 175 tanks per week, 700 tanks per month. one factory, one assembly line, 700 tanks monthly, more than Germany’s entire King Tiger production for the entire war. The workers were predominantly women. At peak production, 68,000 people worked for Fisher Body across all facilities with approximately 30.

7% being women by the end of 1943. Many had never worked in manufacturing before the war. Some were former teachers, secretaries, or homemakers. They learned to weld, rivet, machine parts, and assemble complex mechanical systems in weeks. Compare that to German tank production, which required skilled machinists with years of training.

Germany couldn’t replace skilled workers lost to conscription or casualties. America trained replacements in 2 weeks and put them on the assembly line. The assembly process was ruthlessly efficient. Sherman holes moved down the line on wheeled carriages. At each station, workers installed specific components.

Transmission here, suspension there, engine at the next station, turret at the final position. Every worker performed the same task repeatedly, becoming extraordinarily proficient through repetition. Quality control was continuous. Inspectors checked every component at every stage. Defects were identified immediately and corrected before they propagated down the line. Finished tanks underwent brief function tests.

Engine start, transmission check, turret traverse, gun elevation, then were driven onto rail cars for shipment. From raw steel to finished tank, approximately 1,200 man hours. Compare that to the King Tigers, 14,000 man-hour. Nearly 12 times as long. Fisher Body Grand Blanc produced 11,385 M4 Sherman tanks between April 1942 and May 1945. That’s one factory.

General Motors operated multiple tank production facilities. Chrysler built Shermans at the Detroit Tank Arsenal. Ford, American Locomotive Company, Baldwin Locomotive Works, Lima Locomotive Works, Press Steel Car Company, Pacific Car and Foundry Company, and Federal Machine and Welder Company. All built Sherman variants.

Total Sherman production 49,234 tanks of all variants from 1942 to 1945. 49,234 tanks. Germany built 489 King Tigers. The arithmetic is brutal. America produced 100 Shermans for every King Tiger Germany built. But the disparity becomes even more striking when examining manh hours. King Tiger 14,000 man hours per tank times 489 tanks equals 6,846,000 man hours total.

Sherman fisher body alone, 1200 man-h hours per tank times 11,385 tanks equals 13,662,000 man-h hours. One American factory invested twice as many man-hour as the entire German King Tiger program and produced 23 times as many tanks. Expand to all Sherman production. 49,234 tanks times 1,200 man-h hours equals 59,80,800 man hours.

59 million man-h hours building Shermans, 7 million man-h hours building King Tigers. America invested 8 times as much labor and produced 100 times as many tanks. This is what industrial capacity looks like. This is what happens when a nation with massive manufacturing infrastructure converts that infrastructure to military production using modern mass production techniques.

Germany never had a chance. Lieutenant Colonel William B. Lovely commanded a Sherman tank battalion in Europe. His afteraction reports documented the brutal reality of Sherman versus King Tiger combat. One of his Shermans turned the corner of a house and got off three shots at the front of a panther. All bounced off.

The Sherman then backed behind the corner and was disabled by a shot penetrating two sides of the house plus the tank. That was against a panther, a medium tank. King Tigers were even more dominant. The standard American tactical doctrine for engaging King Tigers was don’t. If you encountered a King Tiger, call for air support, artillery, or tank destroyers.

If you absolutely had to engage with Shermans, the doctrine called for four to five Shermans maneuvering simultaneously to flanking positions. The first Shermans would die. Their job was to draw the King Tiger’s attention and fire. While the King Tiger was reloading, approximately 8 seconds per shot, the flanking Shermans would attempt close-range shots at side or rear armor. It was a numbers game.

Sacrifice two or three Shermans to kill one King Tiger. Brutal, costly, but mathematically sustainable because America had 50 Shermans for every German heavy tank. German tankers knew this. SS Obersharfur Rudolph von Ribbentrop who commanded King Tigers in Normandy later wrote, “We could destroy any Allied tank at ranges they couldn’t even reach us.

But for every tank we destroyed, three more appeared, then five more, then 10. Eventually, you run out of ammunition or get flanked or get hit by artillery.” It didn’t matter how good our tanks were. There were always more Shermans. This was the fundamental asymmetry. The King Tiger was tactically superior.

It could destroy any Allied tank with a single shot from ranges that made return fire impossible. But Germany couldn’t build enough King Tigers to hold territory against enemies who could afford to sacrifice three tanks to kill one. The King Tigers tactical superiority meant nothing when mechanical failures immobilized more tanks than combat losses.

The 700 horsepower Maybach HL230 engine was designed for the 45tonon Panther. The King Tiger weighed 70 tons, 55% heavier. The engine was constantly overworked, overheated, and overstressed. Transmission failures were endemic. The Maybach OLV OG40 1216 transmission connected to the Henchel L81 double radius steering system couldn’t handle the sustained stresses of moving 70 tons cross country.

Irwin Aers Henel’s chief designer later admitted the failure occurred because the Tiger 2 went into production without considering the test results. The first operational deployment illustrated the problem. SS Heavy Pancer Battalion 501 arrived on the Eastern Front with 45 King Tigers. Only eight were operational. The rest suffered final drive failures, transmission breakdowns, or engine problems. They never saw combat.

They broke down and route to the front. The Panzer Lair Division received their first five King Tigers in June 1944 for the Normandy campaign. All five broke down before they could engage the enemy. Crews destroyed them to prevent capture. Even when King Tigers reached combat, reliability was abysmal.

The interled road wheel system designed to distribute weight became a maintenance nightmare. Mud and debris packed between wheels, freezing overnight on the Eastern Front. Crews had to thaw the suspension with blowtorrches before the tanks could move. In wet conditions, a single damaged inner wheel required eight hours to replace because outer wheels had to be removed first. Fuel consumption was catastrophic.

The King Tiger consumed approximately 1 mile for every 4.2 gall of fuel. Germany was desperately short of fuel by 1944. King Tigers frequently ran out of fuel mid operation, becoming immobilized pill boxes until fuel trucks arrived, if they arrived. The Sherman, by comparison, was mechanically reliable.

The twin GM 6046 diesel engines in the M4 A2 variant were derived from proven commercial bus engines. They were reliable, maintainable, and fuel efficient. Sherman crews could perform basic field maintenance with standard tools. Transmission failures were rare.

The simple suspension system using vertical ute springs required minimal maintenance. When Shermans broke down, and they did, repair was straightforward because parts were interchangeable and readily available. When King Tikkers broke down, repair required specialized tools, skilled mechanics, and parts that often didn’t exist in field supply stocks.

Field reports documented that approximately 50 of the 489 King Tigers built were lost to mechanical failure or abandonment, not combat. That’s more than 10% of total production abandoned because they couldn’t be repaired or recovered. Why did Germany build the King Tiger? The answer reveals fundamental strategic blindness that doomed the Nazi war effort.

German doctrine emphasized qualitative superiority, building the best individual weapons regardless of cost or production constraints. This philosophy worked when Germany faced smaller enemies with limited industrial capacity. It failed catastrophically against the United States and Soviet Union. German military planners knew they couldn’t match Allied production.

They believed superior weapons would compensate for inferior numbers. One Tiger should defeat three Shermans. One King Tiger should defeat five. The arithmetic was compelling in theory. In practice, it failed because one, production ratios exceeded combat loss ratios. Germany needed each King Tiger to destroy 100 Shermans to match production rates. That was impossible.

Even the best crews rarely achieved more than 10 kills before mechanical failure, fuel exhaustion, or overwhelming numbers forced withdrawal or destruction. Two, training and crew quality couldn’t scale. German tank crews were superb when they had time to train. By 1944, new crews received minimal training before deployment.

A hastily trained crew in a King Tiger was inferior to an experienced crew in a Sherman, and America had far more crews and far more training capacity. Three, logistics became impossible. King Tigers required specialized recovery vehicles, skilled mechanics, precision parts, and enormous fuel supplies. Germany’s logistic system couldn’t support them. Allied bombing destroyed supply lines.

Fuel shortages immobilized tanks. Spare parts didn’t reach the front. Even when Germany had operational King Tigers, they often sat immobilized, waiting for fuel or parts. Four, tactical superiority meant nothing strategically. Individual King Tiger versus Sherman engagements favored Germany. But wars aren’t won by individual tank duels.

They’re won by sustained campaigns where logistics, production capacity, and force replacement determine outcomes. America could afford to lose three Shermans to kill one King Tiger and still have numerical superiority afterward. Germany couldn’t afford to lose any King Tigers because replacements weren’t available.

General Patton, whose third army faced King Tigers in France, publicly defended the Sherman. The Sherman has a greater mobility, allowing it to attack the enemy strategically rather than with brute force. Since the Third Army became operational, our total tank casualties have amounted to 1,136 tanks.

During the same period, we have accounted for 2,287 German tanks. Patent understood what German planners didn’t. Quantity has a quality all its own. Superior individual weapons don’t win wars when you can’t build enough of them to hold territory against an enemy with overwhelming production capacity.

At Grand Blanc High School in Michigan, a bronze plaque displays a letter from General Patton thanking the people of Grand Blanc for building what he called the best tank. Patton’s praise was partly political, maintaining morale among the workers who built his tanks, but it also reflected a crucial truth. The Sherman wasn’t the best tank because of its specifications.

It was the best tank because it could be built in overwhelming numbers by workers who learned the job in 2 weeks. Those workers were predominantly women. With able-bodied men conscripted from military service, American industry turned to women to fill the void. At Fiser Body, women constituted 30.7% of the workforce by end of 1943. Many had never worked in manufacturing.

They learned welding, riveting, machining, hydraulics, electrical systems, and assembly procedures through brief training programs. Training consisted of multiple classes preparing workers for jobs they’d never completed before, 2 weeks typically.

Then they were on the assembly line building combat vehicles that would be shipped directly to Europe or the Pacific. Compare that to German tank production which required skilled machinists with years of training. Germany couldn’t replace skilled workers lost to military conscription or casualties. The Henchel facility at Castle employed forced labor from concentration camps, but unskilled forced labor couldn’t perform the precision work required for king tiger production. American industry didn’t need precision craftsmen because American engineering had eliminated the

need for hand fitting. Interchangeable parts meant anyone with basic training could assemble a Sherman. The quality came from precision manufacturing at the component level, not from skilled assembly at the final production stage. This was the fundamental innovation that won the war.

Germany built tanks the way craftsmen build furniture. Each piece individually fitted, hand adjusted, personally perfected. America built tanks the way Ford built cars. Standardized components, assembly line production, minimal skill required. One approach created masterpieces. The other created war-winning production capacity.

By April 1945, the war in Europe was ending. Allied forces had captured the Henchel facility at Castle. King Tiger production stopped at 489 units. Fisher Body Grand Blanc was still running, still producing Shermans, still completing 25 tanks per day. The final counting was brutal. King Tigers built 489. King Tigers operational in May 1945, fewer than 20.

King Tigers destroyed in combat approximately 250. King Tigers lost to mechanical failure or abandonment approximately 50. King Tigers captured intact. Multiple examples exist in museums. Shermans built all variants, all factories, 49,234. Shermans lost in combat approximately 4,000 in Europe, thousands more in Pacific.

Sherman’s operational at war’s end, tens of thousands. The Sherman casualty rate was horrific. Crews called them Ronssons after the cigarette lighter because they lit the first time every time. The 75 mm gun was inadequate against German heavy armor. Crews knew they were outmatched, but they won anyway because for every Sherman destroyed, two more arrived, then five more, then 10.

The replacement rate exceeded the casualty rate. German tank forces fought brilliantly, destroyed Allied armor at impressive ratios, and lost anyway because they couldn’t destroy tanks faster than America could build them. The King Tiger represented German engineering at its finest. a nearly perfect tank, individually superior to anything the Allies fielded.

And it meant nothing because wars aren’t won by superior weapons. They’re won by logistics, production capacity, and the ability to sustain operations despite casualties. Germany built masterpieces that required 14,000 man-h hours and 300 skilled craftsmen each.

America stamped out adequate tanks with 1,200 man-h hours and workers who learned the job in 2 weeks. One approach created 489 examples of perfection. The other created 49,234 examples of adequacy and adequacy produced in overwhelming numbers crushed perfection every single time. The arithmetic was always going to win. The craftsmen at Henchel, spending hours handfitting optical rangefinders and individually calibrating road wheels, never had a chance against the assembly line at Grand Blanc, stamping out another Sherman every 58 minutes.

One King Tiger a week, 25 Shermans a day. The war was decided the moment those production rates became reality.

News

Inside Willow Run Night Shift: How 4,000 Black Workers Built B-24 Sections in Secret Hangar DT

At 11:47 p.m. on February 14th, 1943, the night shift bell rang across Willow Run. The sound cut through frozen…

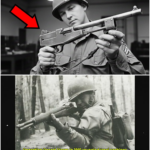

The $16 Gun America Never Took Seriously — Until It Outlived Them All DT

The $16 gun America never took seriously until it outlived them all. December 24th, 1944. Bastonia, Belgium. The frozen forest…

Inside Seneca Shipyards: How 6,700 Farmhands Built 157 LSTs in 18 Months — Carried Patton DT

At 0514 a.m. on April 22nd, 1942, the first shift arrived at a construction site that didn’t exist three months…

German Engineers Opened a Half-Track and Found America’s Secret DT

March 18th, 1944, near the shattered outskirts of Anzio, Italy, a German recovery unit dragged an intact American halftrack into…

They Called the Angle Impossible — Until His Rifle Cleared 34 Italians From the Ridge DT

At 11:47 a.m. on October 23rd, 1942, Corporal Daniel Danny Kak pressed his cheek against the stock of his Springfield…

The Trinity Gadget’s Secret: How 32 Explosive Lenses Changed WWII DT

July 13th, 1945. Late evening, Macdonald Ranchhouse, New Mexico. George Kistakowski kneels on the wooden floor, his hands trembling, not…

End of content

No more pages to load